Hey all,

Came to this forum searching for a solution to my problems. Seems like there's some very knowledgeable users on here and apparently a lot of the advice given has worked for many people.

Unfortunately I have continued to have issues and am now at a bit of a loss.

I bought the wheel super cheap, knowing it had issues. But reading these forums and having heard the symptoms from the previous owner, I felt confident that it was a cracked hall sensor mount or loose magnet.

It arrived and I powered it on and sure enough, it wouldn't calibrate, just twitched limply from left to right periodically. Hopeful that a recalibration using that PC software linked on the PCars forum might just cure it, I ran it and sure enough the wheel seemed fine following the procedure, appearing to complete it's power on auto calibration fine. I also ensure that it was on the latest firmware and all my drivers were up to date. I took it for a few laps of the Red Bull Ring in PCars2 but after no more than 3 laps, the FFB had diminished significantly.

I exited PCars2 and opened the TX Control Panel in Windows and tested with the test effects to rule out a PCars issue. The test effects were also considerably weaker, confirming it was the wheel. Another symptom was the rotation speed which was slower going left and faster going right. I confirmed this by moving the wheel by hand to the left and the centre spring fired it right back to centre quickly. Moving the wheel by hand to the right and letting go resulted in a limp and slow move left back to centre.

I unplugged the wheel and plugging back in resulted in the failure to auto calibrate and just twitching left and right every now and again.

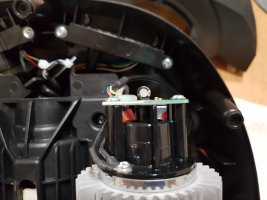

I cracked open the case and inspected the hall sensor mount. The mount was not cracked at any point and was perfectly fine. The magnet was securely fixed to the motor shaft. I remade the solder joints on the hall sensor board where the wire attached as they didn't look fab and cleaned the magnet and hall sensor board with 99% IPA.

Leaving the cover off and putting the fan into forced cooling mode to rule out overheating, I reran the manual calibration tool and the wheel auto calibrated fine on next plug in.

I then repeated the test on Red Bull Ring but sure enough, the FFB went weak at the same point. Feeling the fins on the motor, it was barely warm. Same issues in the TX Control Panel test forces and same slow left rotation speed problems.

It might just be goosed but I'm hopeful somebody here may know of other avenues of investigation. Would be supremely grateful for any pointers.

If you made it this far then well done, and thanks for reading!

Came to this forum searching for a solution to my problems. Seems like there's some very knowledgeable users on here and apparently a lot of the advice given has worked for many people.

Unfortunately I have continued to have issues and am now at a bit of a loss.

I bought the wheel super cheap, knowing it had issues. But reading these forums and having heard the symptoms from the previous owner, I felt confident that it was a cracked hall sensor mount or loose magnet.

It arrived and I powered it on and sure enough, it wouldn't calibrate, just twitched limply from left to right periodically. Hopeful that a recalibration using that PC software linked on the PCars forum might just cure it, I ran it and sure enough the wheel seemed fine following the procedure, appearing to complete it's power on auto calibration fine. I also ensure that it was on the latest firmware and all my drivers were up to date. I took it for a few laps of the Red Bull Ring in PCars2 but after no more than 3 laps, the FFB had diminished significantly.

I exited PCars2 and opened the TX Control Panel in Windows and tested with the test effects to rule out a PCars issue. The test effects were also considerably weaker, confirming it was the wheel. Another symptom was the rotation speed which was slower going left and faster going right. I confirmed this by moving the wheel by hand to the left and the centre spring fired it right back to centre quickly. Moving the wheel by hand to the right and letting go resulted in a limp and slow move left back to centre.

I unplugged the wheel and plugging back in resulted in the failure to auto calibrate and just twitching left and right every now and again.

I cracked open the case and inspected the hall sensor mount. The mount was not cracked at any point and was perfectly fine. The magnet was securely fixed to the motor shaft. I remade the solder joints on the hall sensor board where the wire attached as they didn't look fab and cleaned the magnet and hall sensor board with 99% IPA.

Leaving the cover off and putting the fan into forced cooling mode to rule out overheating, I reran the manual calibration tool and the wheel auto calibrated fine on next plug in.

I then repeated the test on Red Bull Ring but sure enough, the FFB went weak at the same point. Feeling the fins on the motor, it was barely warm. Same issues in the TX Control Panel test forces and same slow left rotation speed problems.

It might just be goosed but I'm hopeful somebody here may know of other avenues of investigation. Would be supremely grateful for any pointers.

If you made it this far then well done, and thanks for reading!