Tiago, I was triyng to find you becouse I needed help with the hall sensors, of couse like you I'm not big fan of this, But I really hate the plastic on simracing like shifter g27, but finally I could make a code for halls sensor. Thank you for your video, really was very help for my. I'm also making a H pattern shifter and seq shifter, but now I need focus on my handbrake. ohh here is the video with hall sensors. Just the concept that I will put on my H pattern Shifter.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HS6-GT – DIY H-Pattern Shifter

- Thread starter Bitacaia

- Start date

Hi GSingle!Making good progress...

The three parts of the main case are printed in Black Filament-PM CFJET (PETG+Carbon Fibre) and the two parts of the offset selector are printed in Polymaker PCMAX (Polycarbonate). These should stand up well to the roller bearing and hopefully no need for POM.

View attachment 417626

View attachment 417627

I made a few modifications:

Very pleased with progress so far and thanks to Tiago for the hard work put into this design. The effort that went into this is evident from the quality of the design.

- Added two extra holes on the top surface so I can support the finished shifter on 4040 profiles at both ends. Created an extra part that is flush with the top plate of the gear lever an creates two extra mounting points at the other end.

- Reversed the nuts/bolts that hold the lever to the top face of the shifter, so the nuts are captive inside and the bolts, hex button heads, are on the outside, for cleaner look.

- Recessed the bolts holding the bottom case and changed to M6x35mm Allen Cap head bolts so that the bottom is flat with nothing sticking out.

- Going to look at mounting hall effect sensors rather than microswitches.

Just waiting for the rest of the hardware and gear lever to arrive although I'm having real trouble trying to find the M5x25x8oD round nuts. Can find plenty of 20mm ones, but none that are 25mm long and 8mm OD.

When finished its going here:

View attachment 417630

I really like the clean look of the Bottom Case.

Although is cool to have Petg with Carbon fiber, I don´t believe the Outer Cases will require such a good material. Simple PLA do the work. But if you can afford it, it is perfect. And I like the shine of the material.

The "Offset Lever" can take advantage with this material, for sure!!! I hope you make a reliability report!

In relation to the Hall sensor. I never made available any 3d model to fix them (I think). so, i put a link for them here:

Fusion 360:

Stl:

HS6_GT-HES_HOLDER.stl

drive.google.com

drive.google.com

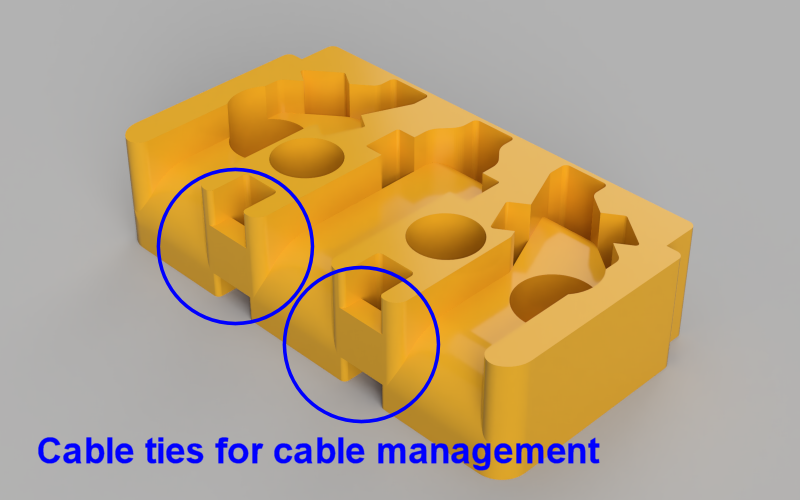

The blue marking are holes to put zip-ties for electric cable management.

I hope you can make arduino sketches. I made a very simple one, since I'm not got at it. The one available for the microswitches was made by other user. And he implemented the Reverse function on the 6th gear slot. Using my basic sketch, and adapting the Reverse gear, for me would be impossible. I hope you can find a solution for that

any more question, feel free to ask.

Tiago Viana

Hi Mr Pucho.Tiago, I was triyng to find you becouse I needed help with the hall sensors, of couse like you I'm not big fan of this, But I really hate the plastic on simracing like shifter g27, but finally I could make a code for halls sensor. Thank you for your video, really was very help for my. I'm also making a H pattern shifter and seq shifter, but now I need focus on my handbrake. ohh here is the video with hall sensors. Just the concept that I will put on my H pattern Shifter.

How can i help you with the Hall sensors? From the video you have it working!

What type of hall sensor you are using? I like to use a linear effect Hall sensor. That means, it can detect the distance of the magnetic field, giving you more control over the activation point of the gear over the software side. If you use a switch type Hall Sensor, then you need to play with the magnetic field force of the magnet for the activation point.

I use this one:

Allegro A1301 or A1302 (i don´t know exactly the one i have, but they are the same)

best regards

Tiago Viana

Would be happy to change the sketch for hall sensors, should be quite straight forward. Might need some sort calibration mode as magnets can change over time. Maybe a gear change from 5th to 2nd gear within a second and then go 1-2-3-4-5-6 to calibrate. This would allow the on and off values for the hall sensors to be established automatically, with a small safety margin added, and then stored in (pseudo) EEPROM. Would be nice to also have a single LED so that we could be certain we're in calibration mode (flashing). This LED would also be good for the 6th to 1st reverse mode, as we could be certain reverse was selected, although I guess it would be on-screen too. Where could we put an LED? Another idea might be to add a switch on the column to add 7th gear, a bit like overdrive on on old cars, although routing wires would be very difficult with the sx200 shifter.Hi GSingle!

I really like the clean look of the Bottom Case.

Although is cool to have Petg with Carbon fiber, I don´t believe the Outer Cases will require such a good material. Simple PLA do the work. But if you can afford it, it is perfect. And I like the shine of the material.

The "Offset Lever" can take advantage with this material, for sure!!! I hope you make a reliability report!

In relation to the Hall sensor. I never made available any 3d model to fix them (I think). so, i put a link for them here:

Fusion 360:

Stl:

HS6_GT-HES_HOLDER.stl

drive.google.com

View attachment 417697

The blue marking are holes to put zip-ties for electric cable management.

I hope you can make arduino sketches. I made a very simple one, since I'm not got at it. The one available for the microswitches was made by other user. And he implemented the Reverse function on the 6th gear slot. Using my basic sketch, and adapting the Reverse gear, for me would be impossible. I hope you can find a solution for that

any more question, feel free to ask.

Tiago Viana

Graham

Hi Tiago,

Nearly finished building my shifter. I had to modify the STL you posted to hold the hall effect sensors as there wasn't enough clearance. As the sensor holder sits closer to the selector it was fouling on the internal structure of the upper case. I also enlarged the holes for the cable ties on the underside of the holder as using cable ties on the top fouls the two round nuts that protrude from the selector. To help with cable management I also added two loops for cable ties.

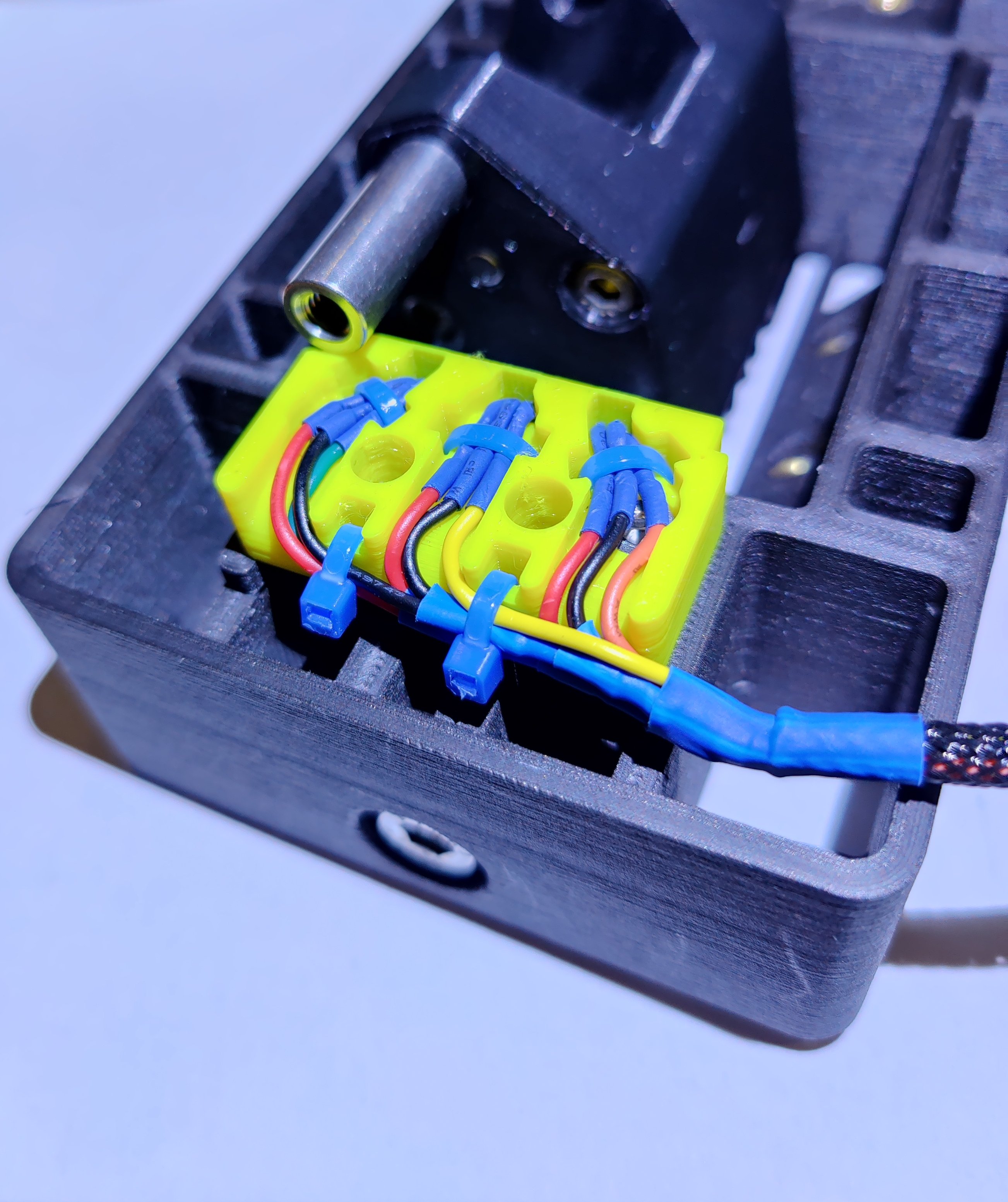

This is the result:

I'm working on an updated sketch that will work with the hall effect sensors and I'll post it when complete. I'm including:

Nearly finished building my shifter. I had to modify the STL you posted to hold the hall effect sensors as there wasn't enough clearance. As the sensor holder sits closer to the selector it was fouling on the internal structure of the upper case. I also enlarged the holes for the cable ties on the underside of the holder as using cable ties on the top fouls the two round nuts that protrude from the selector. To help with cable management I also added two loops for cable ties.

This is the result:

I'm working on an updated sketch that will work with the hall effect sensors and I'll post it when complete. I'm including:

- Access to a mode that stores calibration data for each hall sensor for reliable shifing.

- An optional RGB indicator LED that will show green for neutral, red for reverse, flashing yellow if not connected to a PC and flashing blue when in hall sensor calibration mode.

- Maybe an plug-in 8 segment LED gear indicator.

Last edited:

The petg with carbon fibre looks great! The only way you can share the stl file is by uploading it to google drive (or something similar) and share the link here. I'm going to try printing the offset leaver in polycarbonate too. What magnet did you use and where did you put it?Hi Tiago,

Nearly finished building my shifter. I had to modify the STL you posted to hold the hall effect sensors as there wasn't enough clearance. As the sensor holder sits closer to the selector it was fouling on the internal structure of the upper case. I also enlarged the holes for the cable ties on the underside of the holder as using cable ties on the top fouls the two round nuts that protrude from the selector. To help with cable management I also added two loops for cable ties.

This is the result:

View attachment 419849

I'm working on an updated sketch that will work with the hall effect sensors and I'll post it when complete. I'm including:

I can send the STL if its useful. Don't seem to be able to attach it to a post.

- Access to a mode that stores calibration data for each hall sensor for reliable shifing.

- An optional RGB indicator LED that will show green for neutral, red for reverse, flashing yellow if not connected to a PC and flashing blue when in hall sensor calibration mode.

- Maybe an plug-in 8 segment LED gear indicator.

Tiago added the magnet holes already. I used these magnets: Magnet Expert 5mm dia x 4mm thick N42 Neodymium Magnet - 0.86kg Pull ( Pack of 20 ): Amazon.co.uk: DIY & Tools

When placing the magnets, make sure that their poles are reversed at either end of the selector, if you don't do this you'll have to customise the sketch to differing polarities for 1-3-5 and 2-4-6. The easiest way is to stick the two magnets together and then reverse one of them. Ideally, you want the north poles sticking out. Just superglue them in the recesses that Tiago already made on the selector.

I've written a new version of sketch for the hall effect sensors. After writing and testing it, it became apparent that a calibration mode was not necessary. Still, I added a parameter so you can tune the sensitivity of the Hall effect sensors if needed although I suspect the default will work fine in most cases. I went with the Honeywell 49E (SS49E) hall effect sensors: 5x Hall Effect Sensor Linear Ratiometric 49E SS49E Electric Bike Throttle Repair 7426000132160 | eBay

I also added support for an indicator light: which shows green in neutral and red in reverse, goes out when in gear.

I need to tune the sketch slightly as the tri-colour LED flickers a bit and will then post the STL for the hall effect holder and the sketch.

Graham

When placing the magnets, make sure that their poles are reversed at either end of the selector, if you don't do this you'll have to customise the sketch to differing polarities for 1-3-5 and 2-4-6. The easiest way is to stick the two magnets together and then reverse one of them. Ideally, you want the north poles sticking out. Just superglue them in the recesses that Tiago already made on the selector.

I've written a new version of sketch for the hall effect sensors. After writing and testing it, it became apparent that a calibration mode was not necessary. Still, I added a parameter so you can tune the sensitivity of the Hall effect sensors if needed although I suspect the default will work fine in most cases. I went with the Honeywell 49E (SS49E) hall effect sensors: 5x Hall Effect Sensor Linear Ratiometric 49E SS49E Electric Bike Throttle Repair 7426000132160 | eBay

I also added support for an indicator light: which shows green in neutral and red in reverse, goes out when in gear.

I need to tune the sketch slightly as the tri-colour LED flickers a bit and will then post the STL for the hall effect holder and the sketch.

Graham

I completed the sketch and fixed the flickering LED. You can can download it here:

drive.google.com

drive.google.com

The updated STL for the Hall effect sensor holder is here:

https://drive.google.com/file/d/1yajACA6yQEs64r3aqhbsdQIl94EKXNiJ/view?usp=sharing

Note: Tiago has already added two recesses to hold the 5mm magnets on the selector, one either end. Note the comment in my previous post today about magnet polarity.

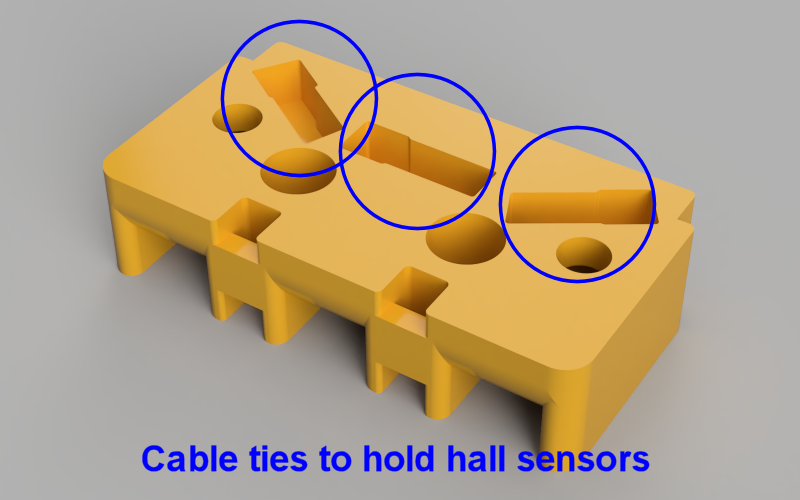

No support material is required for the hall sensor holder, but you will need to clean out one of the holes for each of the cable ties that hold the hall sensors in place. Print it in the orientation of the first image below.

Use the loops on the back edge of the holder for cable ties that aid cable management.

Use the holes on the underside for cable ties that hold the hall sensors in place. Thread the cable ties up from the bottom and then back down again so that close underneath the holder. Use small cable ties so the bulge with the cable tie latch will sit flush with the base of the holder, in each of the 3 square cut-outs.

HS6-GT-Sketch_V1.3_Hall_Effect_Sensors.ino

drive.google.com

drive.google.com

The updated STL for the Hall effect sensor holder is here:

https://drive.google.com/file/d/1yajACA6yQEs64r3aqhbsdQIl94EKXNiJ/view?usp=sharing

Note: Tiago has already added two recesses to hold the 5mm magnets on the selector, one either end. Note the comment in my previous post today about magnet polarity.

No support material is required for the hall sensor holder, but you will need to clean out one of the holes for each of the cable ties that hold the hall sensors in place. Print it in the orientation of the first image below.

Use the loops on the back edge of the holder for cable ties that aid cable management.

Use the holes on the underside for cable ties that hold the hall sensors in place. Thread the cable ties up from the bottom and then back down again so that close underneath the holder. Use small cable ties so the bulge with the cable tie latch will sit flush with the base of the holder, in each of the 3 square cut-outs.

Last edited:

Hi GSingle,

Congratulation on your shifter!!! The work you made is impressive! Thank you for sharing the modified models and Arduino Sketch.

And can you share the your opinion on the shifter? And suggest some improvements!

I will add your information on the first page, and on thingiverse if you don´t mind.

Tiago Viana

Congratulation on your shifter!!! The work you made is impressive! Thank you for sharing the modified models and Arduino Sketch.

And can you share the your opinion on the shifter? And suggest some improvements!

I will add your information on the first page, and on thingiverse if you don´t mind.

Tiago Viana

Changing subject,

I'm posting this impressive video made by Stefan from CNC Kitchen. The idea is to re-melt the plastic from the 3d printed model, so the layers fuse together, and in the end giving a more strength to the part.

and to complement, the original idea:

Since I'm noticing that the layer adhesion is a problem of the Offset Lever, I'm thinking that this trick can help us.

I believe it will be require to print the part with 100% infill, without hollow areas.

If anyone is interest in testing, share the results. I will make the same.

I will go crazy and probably try first with flour because I don't have a good grinder to grind the salt to a fine powder...

Tiago Viana

I'm posting this impressive video made by Stefan from CNC Kitchen. The idea is to re-melt the plastic from the 3d printed model, so the layers fuse together, and in the end giving a more strength to the part.

and to complement, the original idea:

Since I'm noticing that the layer adhesion is a problem of the Offset Lever, I'm thinking that this trick can help us.

I believe it will be require to print the part with 100% infill, without hollow areas.

If anyone is interest in testing, share the results. I will make the same.

I will go crazy and probably try first with flour because I don't have a good grinder to grind the salt to a fine powder...

Tiago Viana

Looks very interesting. I'd wait 3 months and someone will be selling a specialist power for this purpose that gives good results without wrecking all your kitchen equipment. Fine salt power will corrode everything steel it lands on and there was a lot of fine power drifting around. I'm definitely going to keep an eye on this process, but it's too much work at the moment, just like annealing PLA.

Regarding the shifter, I've mounted it but unfortunately the USB plug detached from the Arduino and I now have to take it apart and fit an new Arduino When time permits, I'll re-print the bottom case with the USB connector inside and a cord grip for the USB cable. I don't need to be able to unplug at the shifter end of the cable and I don't want a repeat of this problem.

When time permits, I'll re-print the bottom case with the USB connector inside and a cord grip for the USB cable. I don't need to be able to unplug at the shifter end of the cable and I don't want a repeat of this problem.

I went with the stiffer springs and so far, without using the shifter in-game, I prefer them. I think the shifter could do with some sort of gate mechanism to make it easier when you're moving across the box, otherwise I can see issue with blocked shifts. I had an Idea about profiling the ends of the two M6 round nuts on the selector to assist with this, I wonder if a half chamfer on one side might be enough? The issue would be stopping them spinning round on the M6 bolt from the selector. I'll think about it some more.

I'll post some video once I have it running in game.

Regarding the shifter, I've mounted it but unfortunately the USB plug detached from the Arduino and I now have to take it apart and fit an new Arduino

I went with the stiffer springs and so far, without using the shifter in-game, I prefer them. I think the shifter could do with some sort of gate mechanism to make it easier when you're moving across the box, otherwise I can see issue with blocked shifts. I had an Idea about profiling the ends of the two M6 round nuts on the selector to assist with this, I wonder if a half chamfer on one side might be enough? The issue would be stopping them spinning round on the M6 bolt from the selector. I'll think about it some more.

I'll post some video once I have it running in game.

Last edited:

Hi Graham,Looks very interesting. I'd wait 3 months and someone will be selling a specialist power for this purpose that gives good results without wrecking all your kitchen equipment. Fine salt power will corrode everything steel it lands on and there was a lot of fine power drifting around. I'm definitely going to keep an eye on this process, but it's too much work at the moment, just like annealing PLA.

Regarding the shifter, I've mounted it but unfortunately the USB plug detached from the Arduino and I now have to take it apart and fit an new ArduinoWhen time permits, I'll re-print the bottom case with the USB connector inside and a cord grip for the USB cable. I don't need to be able to unplug at the shifter end of the cable and I don't want a repeat of this problem.

I went with the stiffer springs and so far, without using the shifter in-game, I prefer them. I think the shifter could do with some sort of gate mechanism to make it easier when you're moving across the box, otherwise I can see issue with blocked shifts. I had an Idea about profiling the ends of the two M6 round nuts on the selector to assist with this, I wonder if a half chamfer on one side might be enough? The issue would be stopping them spinning round on the M6 bolt from the selector. I'll think about it some more.

I'll post some video once I have it running in game.

Regarding the gates: I was hoping the round shape of the M6 bolts to be enough to help slot the Offset Lever in the desire position.

But, I have other idea to get the gates more easy to engage. You could shave with a file the M6 Bolts that makes the slot pattern. The way they fit in the case, they don't rotate, the cost of making different shapes is minimal and you can easily replace them without much disassembly.

Tiago Viana

Casting isn't so easy. The process is easy, just melt aluminum on a mould. The problem, you need specific hardware. and if you don't have this hardware, you need to buy... just for making a small part. in the end, you spend so much money for nothing. with that money, you can buy a better and reliable shifter, like the PRO Sim shifter or the Fanatec...Learn how to cast it out of metal and that shifter will be amazing

What do you miss ?

Sorry, I could have been more clear. How do I open the model in fusion? It only seems to open in a web page.

I checked the link, I think Tiago needs to update the link and enable the download permission?

Small update: I did the hall sensor upgrade and it works great! Thanks gsingle for the files. I also printed the offset leaver in polycarbonate with 5 wall lines, hope this works better.

A small question: what springs and size do you guys use?

Small update: I did the hall sensor upgrade and it works great! Thanks gsingle for the files. I also printed the offset leaver in polycarbonate with 5 wall lines, hope this works better.

A small question: what springs and size do you guys use?

Last edited:

Latest News

-

2023 Racing Series Officially in Sim RacingThere are so many sim racing games out there aiming to recreate official real-world racing...

- Angus Martin

- Updated:

- 6 min read

-

Most Played Racing Games On Steam In April 2024Spring has arrived in most of the Northern Hemisphere, and it shows in the player numbers of...

- Yannik Haustein

- Updated:

- 3 min read

-

2024 Formula One Miami Grand PrixFrom new liveries to groundbreaking team personal changes, here's everything that's gone down in...

- Connor Minniss

- Updated:

- 3 min read

-

2003 NASCAR Cup Cars Scanned For iRacingDale Earnhardt Jr. Has been at it again, teasing future iRacing content that will bring those...

- Thomas Harrison-Lord

- Updated:

- 2 min read

-

Automobilista 2: 2024 F1 Liveries For New F-Ultimate Gen 2 CompleteJust in time for the 2024 Miami Grand Prix, the current season's liveries for the reworked...

- Yannik Haustein

- Updated:

- 2 min read

-

PISTA Motorsport: New Dev Log Announces Early Access, Confirms ModsPISTA Motorsport developer REG Simulations is back with another dev log for their project...

- Yannik Haustein

- Updated:

- 3 min read

-

World of Outlaws: Dirt Racing 24 is iRacing’s Dirt Oval SequelA sequel to the critically well-received World of Outlaws: Dirt Racing will slide into view this...

- Thomas Harrison-Lord

- Updated:

- 2 min read