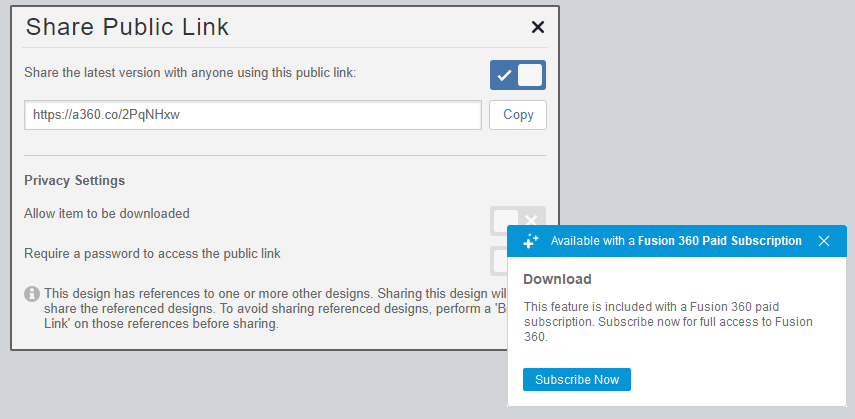

Funny... i tried to make a new link, but i have this problem... I don´t know what it means... Does just the first option allow you do have access to the parametric models? Or it needs to be the Download option activated?

The share link is the same as the one in the first post. So, i have now clue what to do.

The share link is the same as the one in the first post. So, i have now clue what to do.