You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mobile Driving/Flying Cockpit with Motion and Tactile ( Build )

RCHeliguy

Premium

At long last, I'm pleased to see that character banished from the forum. Hopefully Discord follows suit.

Contributed nothing but shithousery from day one.

I agree completely, but don't be sure he is gone yet.

EDIT: I've received quite a few messages from people on FB and Discord who echo your sentiment about TonyMM. I just heard that some people actually did try to verify his identity and they never found record of anyone with his reported name in GT2.

Who is Simracer_911 or Funracing ? Their accounts were being used to react to his and my recent comments but they have never messaged on RaceDepartment and have completely private accounts.

Last edited:

Problem for me is that these are hard to find. Is there a central store or something like that where these can be found?Paying for profiles is not something that sits well with the Simhub developer, Wotever. So this is going to be a very tricky subject. Does one selling profiles need to pay a commission to Simhub for the ability to create and share those profiles? The business model is very messy given the program being utilised belongs to no one in the Simtag venture.

I've forgotten about the profiles. I don't foresee them coming to anyone that is not part of the internal beta testing program and honestly it's not worth the hassle. The amount of recently shared effects and profiles, completely free and for the love of the hobby, is more than enough to enjoy tactile with whatever units you have.

Last edited:

Problem for me is that these are hard to find. Is there a central store or something like that where these can be found?

Unfortunately not. The Simhub Discord has some spread across the bass shaker channels and I've collected my fair share and put them into a library of sorts if and when I ever need to bring them up again. I tend to just keep the most relevant stuff for me, create a profile out of it and move on.

I do agree that having some sort of depository for user created effects ala SimVibe with SimXperience but at this stage there is no such thing. I'm surprised that there hasn't been a channel created for hosting user created effects in the Discord server. It would seem the most obvious way to collate and organise things.

RCHeliguy

Premium

Hopefully this bit of drama is over now.

I like to believe it's obvious from the content of this 3 year long build thread that working on my rig is a passion project for me and like many here at Race Department I do take some pride in my rig and have enjoyed sharing my journey to date.

I've tried to document how I've done things to give others ideas and since I got a 3D printer and have been able to design things for my sim rig that others could use, I've shared them here.

www.thingiverse.com

www.thingiverse.com

I have found that Thingiverse has some issues and some of my projects do not display under my profile and it is sometimes hard to even point people to projects that won't even show up for me anymore.

While I won't take down my Thingiverse page, I'm planning to migrate all of my projects over to the Prusa Printers site which seems better managed. I believe Prusa is doing a good job to create an open space for 3D print files and has been adding new features and evolving their 3D file repository features in a way that works better and they are trying to open it up. The key to me is that it always works.

www.prusaprinters.org

www.prusaprinters.org

My STL files will always be there to be sliced for any printer. However Prusa is setup to take my PrusaSlicer files in a useful way that tells you how much filament will be used and what the print time will be if you use the same settings as I did and allow me to include any supports if needed etc.. Since PrusaSlicer also has profiles for other printers this may also make it easier to just switch a project profile in PrusaSlicer to an Ender 3 for example while keeping everything else the same.

As far as metal work goes.

I did upgrade to a licensed version of Fusion 360. I decided that I had gotten some great use out of Fusion 360 over the last year plus and they they deserved my support. I also like the additional unlocked features. I'm considering having some parts outsourced and if I have good luck with these parts, I'll likely share the drawings for them as well.

I've had people ask me for drawings of some of the parts that I've hand machined in my garage and I may revisit some of those.

I'm also finally scheduled for that Bridgeport Mill class next Saturday so I will have access to the mill in my local Maker Space which should be fun.

As always this about the journey, having fun and sharing. Let's try to keep this positive

I like to believe it's obvious from the content of this 3 year long build thread that working on my rig is a passion project for me and like many here at Race Department I do take some pride in my rig and have enjoyed sharing my journey to date.

I've tried to document how I've done things to give others ideas and since I got a 3D printer and have been able to design things for my sim rig that others could use, I've shared them here.

RCHeliGuy's Thingiverse Profile

Having a lot of fun after assembling my first 3D printer in September 2020. Loving Fusion 360 that I've been learning since then as well. I think my designs are interesting, but I am very new to 3D printing and just using default settings from PrusaSlicer. I also know my STL files are...

I have found that Thingiverse has some issues and some of my projects do not display under my profile and it is sometimes hard to even point people to projects that won't even show up for me anymore.

While I won't take down my Thingiverse page, I'm planning to migrate all of my projects over to the Prusa Printers site which seems better managed. I believe Prusa is doing a good job to create an open space for 3D print files and has been adding new features and evolving their 3D file repository features in a way that works better and they are trying to open it up. The key to me is that it always works.

Printables

My STL files will always be there to be sliced for any printer. However Prusa is setup to take my PrusaSlicer files in a useful way that tells you how much filament will be used and what the print time will be if you use the same settings as I did and allow me to include any supports if needed etc.. Since PrusaSlicer also has profiles for other printers this may also make it easier to just switch a project profile in PrusaSlicer to an Ender 3 for example while keeping everything else the same.

As far as metal work goes.

I did upgrade to a licensed version of Fusion 360. I decided that I had gotten some great use out of Fusion 360 over the last year plus and they they deserved my support. I also like the additional unlocked features. I'm considering having some parts outsourced and if I have good luck with these parts, I'll likely share the drawings for them as well.

I've had people ask me for drawings of some of the parts that I've hand machined in my garage and I may revisit some of those.

I'm also finally scheduled for that Bridgeport Mill class next Saturday so I will have access to the mill in my local Maker Space which should be fun.

As always this about the journey, having fun and sharing. Let's try to keep this positive

RCHeliguy

Premium

RCHeliguy

Premium

I'm making a pre-emptive request. I'm going to try to make some vinyl decals this week. It could go well or I may have some learning curve obstacles to figure out.

But the vector art that I got is Race Bass related. Is it OK that I talk about what is involved in creating a vinyl decal with this artwork without creating yet another Race Bass discussion?

So far I've got an svg file and my maker space is setup to use Inkscape. They have a smaller Sihlouette Cameo vinyl cutter.

However it appears that they mostly use the larger format vinyl cutter below.

I'm thinking about making a white decal about 250mm long that could go on the side of my seat and possibly another in black about 185mm long that would fit between the slots of profile.

So far I've learned about:

1. artwork preparation in inkscape. I still have more to learn here.

2. "weeding" where you peel off all the vinyl that you don't want. This is frequently done with tweezers.

3. Putting an adhesive application panel over that.

4. Finally applying the vinyl rubbing it into place and carefully pulling back the application panel.

It doesn't look like rocket science, but I'm sure that there is a lot I haven't figured out yet.

But the vector art that I got is Race Bass related. Is it OK that I talk about what is involved in creating a vinyl decal with this artwork without creating yet another Race Bass discussion?

So far I've got an svg file and my maker space is setup to use Inkscape. They have a smaller Sihlouette Cameo vinyl cutter.

However it appears that they mostly use the larger format vinyl cutter below.

I'm thinking about making a white decal about 250mm long that could go on the side of my seat and possibly another in black about 185mm long that would fit between the slots of profile.

So far I've learned about:

1. artwork preparation in inkscape. I still have more to learn here.

2. "weeding" where you peel off all the vinyl that you don't want. This is frequently done with tweezers.

3. Putting an adhesive application panel over that.

4. Finally applying the vinyl rubbing it into place and carefully pulling back the application panel.

It doesn't look like rocket science, but I'm sure that there is a lot I haven't figured out yet.

Mark:

We all live and learn vicariously thanks to your relentless and intrepid charges into new areas and the extensive amount of time you put into your excellent reports.

Given the range of your projects, this thread should be called "Rig Improvement!"

Please keep it up regardless of the shrill and loud minority naysayers (they and we know who I am talking about).

Sincerely,

Chris

We all live and learn vicariously thanks to your relentless and intrepid charges into new areas and the extensive amount of time you put into your excellent reports.

Given the range of your projects, this thread should be called "Rig Improvement!"

Please keep it up regardless of the shrill and loud minority naysayers (they and we know who I am talking about).

Sincerely,

Chris

dear rcheli

do not let your great report destroyed

maybe its worth to move all rb discussions out of our rig reports

lets focus on your great diy help

your great thingiverse projects

and so much more we gained in the last years

my 5cent, from a passionate rig report writer

peter

do not let your great report destroyed

maybe its worth to move all rb discussions out of our rig reports

lets focus on your great diy help

your great thingiverse projects

and so much more we gained in the last years

my 5cent, from a passionate rig report writer

peter

Last edited:

I have the Silhouette Cameo 4. Certainly not an expert, but a few things I've learned:

- Personally I've found that the better quality vinyl (ie, branded, or a bit more $) tends to cut better especially for designs that are really intricate. Cheap works too, but my experience is not quite to the same reliability. I also have a large role of gloss black that is for vehicle wrapping, which I have not tried to cut yet, but it is a much higher quality and thickness than the general hobby stuff.

- check/clean the blade. Tiny bits of vinyl or paper can get lodged in there especially after an intricate cut. I've solved many frustrations just by cleaning the blade (even when I couldn't see any debris, a good cleaning helped)

- the trickiest part (I found) is to get the blade depth/pressure just right for your vinyl. The software usually has some profile settings, but usually there is a bit of test cutting involved to get it just right. Too deep and you cut the paper underneath. Too shallow and it won't cut through the vinyl fully. Also the cutting speed can make a difference (sometimes faster, is better.....)

- Make sure you have transfer tape (mine came in bigger roll). You can also re-use it several times without any major issues.

- weeding is a PIA. I use a sort of dental-pick thing. Tweezers are fine, but I just find I can get smaller pieces easier with the pick. If the design is really intricate, sometimes it's better to put the entire piece on the transfer tape first, and then weed the pieces off of the transfer tape (from the back).

Attached was one of my first tries after some experimentation. I'm sure I could do a better job now, but the reality is that it tends to take quite a long time.

- Personally I've found that the better quality vinyl (ie, branded, or a bit more $) tends to cut better especially for designs that are really intricate. Cheap works too, but my experience is not quite to the same reliability. I also have a large role of gloss black that is for vehicle wrapping, which I have not tried to cut yet, but it is a much higher quality and thickness than the general hobby stuff.

- check/clean the blade. Tiny bits of vinyl or paper can get lodged in there especially after an intricate cut. I've solved many frustrations just by cleaning the blade (even when I couldn't see any debris, a good cleaning helped)

- the trickiest part (I found) is to get the blade depth/pressure just right for your vinyl. The software usually has some profile settings, but usually there is a bit of test cutting involved to get it just right. Too deep and you cut the paper underneath. Too shallow and it won't cut through the vinyl fully. Also the cutting speed can make a difference (sometimes faster, is better.....)

- Make sure you have transfer tape (mine came in bigger roll). You can also re-use it several times without any major issues.

- weeding is a PIA. I use a sort of dental-pick thing. Tweezers are fine, but I just find I can get smaller pieces easier with the pick. If the design is really intricate, sometimes it's better to put the entire piece on the transfer tape first, and then weed the pieces off of the transfer tape (from the back).

Attached was one of my first tries after some experimentation. I'm sure I could do a better job now, but the reality is that it tends to take quite a long time.

Attachments

RCHeliguy

Premium

Very nice!

Everything you mentioned makes sense. My maker space has vinyl and transfer tape on hand that I can use.

They keep Oracal 651 vinyl in stock in Red, White and Black. It appears to be 2.5mil thick.

This is the Vinyl Cutter page that they just put together for their USCutter SC2 34. It says there is typically a 45 degree blade installed and new blades and other things are kept stocked. Apparently this is their go to cutter there.

I was told that the Sihlouette is an older model Cameo or Cameo 2 and doesn't see much use.

I've got my vector art in two files. One is sized to 250mm wide and the other 185mm wide. I'm thinking that I'll just cut them two across and just use the whole roll for simplicity. 2 x white than 2 x black.

They have transfer paper in the store there and it looks like plenty of tools for weeding. I should only need to show up with a USB drive with my two files and go from there. But I could use my laptop as well.

Everything you mentioned makes sense. My maker space has vinyl and transfer tape on hand that I can use.

They keep Oracal 651 vinyl in stock in Red, White and Black. It appears to be 2.5mil thick.

This is the Vinyl Cutter page that they just put together for their USCutter SC2 34. It says there is typically a 45 degree blade installed and new blades and other things are kept stocked. Apparently this is their go to cutter there.

I was told that the Sihlouette is an older model Cameo or Cameo 2 and doesn't see much use.

I've got my vector art in two files. One is sized to 250mm wide and the other 185mm wide. I'm thinking that I'll just cut them two across and just use the whole roll for simplicity. 2 x white than 2 x black.

They have transfer paper in the store there and it looks like plenty of tools for weeding. I should only need to show up with a USB drive with my two files and go from there. But I could use my laptop as well.

Last edited:

Looks like a much more professional machine than the cameo. Surely they have it dialed in for the Oracal so hopefully no issues.

Good luck!!

I have quite a few decals spread around my house now. Racing flag/name decals are popular (like you see on race car windows/bodies) but depends on the flag intricacy.

Depending on what you apply it to, a heat gun can be handy as well. Oracal is really good and you can often fix mistakes in application with the heat gun. Lots of vids on YouTube to give some techniques there.

If it’s a super flat surface and you want zero bubbles, look into the method to apply them with a soap/water mix. It’s also handy to give some movement to align things before sealing them down. Another trick is to use baking paper (the decal will not really stick). So you just tack down one section then slowly remove the baking paper while sealing it down as you go.

Good luck!!

I have quite a few decals spread around my house now. Racing flag/name decals are popular (like you see on race car windows/bodies) but depends on the flag intricacy.

Depending on what you apply it to, a heat gun can be handy as well. Oracal is really good and you can often fix mistakes in application with the heat gun. Lots of vids on YouTube to give some techniques there.

If it’s a super flat surface and you want zero bubbles, look into the method to apply them with a soap/water mix. It’s also handy to give some movement to align things before sealing them down. Another trick is to use baking paper (the decal will not really stick). So you just tack down one section then slowly remove the baking paper while sealing it down as you go.

Last edited:

RCHeliguy

Premium

I'm planning to apply it to the side of my shell seat and possibly to profile, but I'm less sure of that.

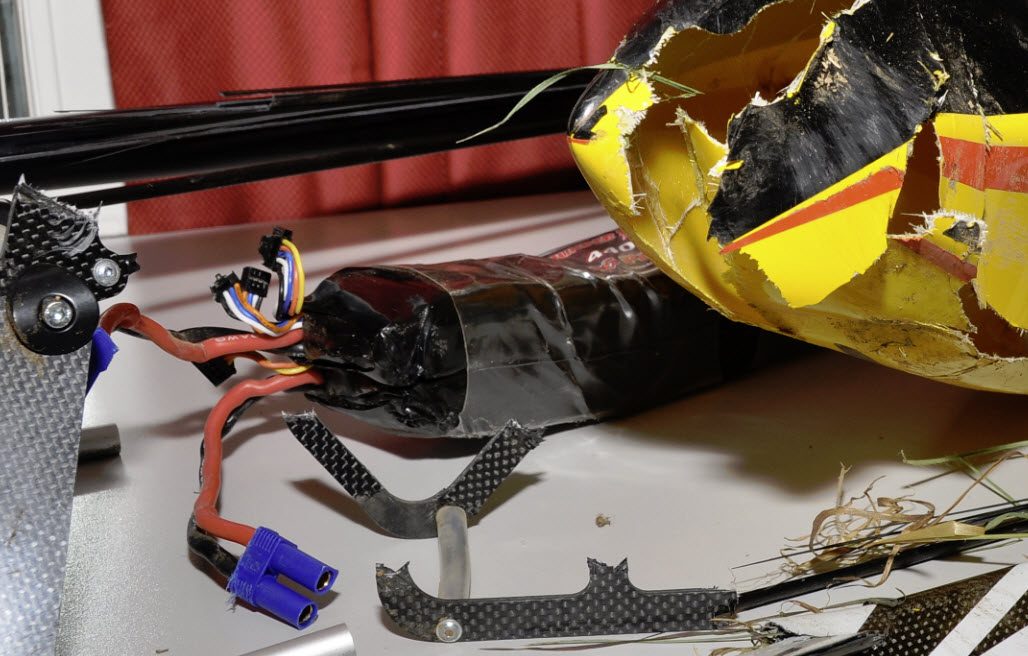

I have a bit of experience applying vinyl using soapy water on my RC Helicopter canopies like the Henseleit TDR in my avatar image. I have never used my heat gun on vinyl before.

The canopy decal is 3 pieces of vinyl and each side has a vinyl comet. It did take some patience to get them perfectly aligned and all the bubbles worked out.

Every crash was a new canopy and more practice applying vinyl

I have a bit of experience applying vinyl using soapy water on my RC Helicopter canopies like the Henseleit TDR in my avatar image. I have never used my heat gun on vinyl before.

The canopy decal is 3 pieces of vinyl and each side has a vinyl comet. It did take some patience to get them perfectly aligned and all the bubbles worked out.

Every crash was a new canopy and more practice applying vinyl

Last edited:

RCHeliguy

Premium

Currently I have a bit of a power cord mess behind my gaming computer that consists of 2 x 6 plug surge outlets.

I have my Computer, front left base station, additional Index power supply, tactile amps, and dsp boxes. The DSP boxes have euro plugs with adapters that make them wide covering 2 plug outlets. So that's 8 plugs. I flip them on and also have a switched plug on my right rear base station.

I wanted to get the outlet tower model with the switch on top since I turn this on manually before I use my gaming computer, but that model had a very long power cord with thin gauge wire and half the surge suppression.

But as soon as I starting thinking about convenience and the fact that I manually flip two switches on opposite ends of the room, I started looking at this Granted there are much less expensive indoor only radio controlled switches but they are only rated for 10A. Lets just hope that they are immune to my rig and don't flip mid game.

Granted there are much less expensive indoor only radio controlled switches but they are only rated for 10A. Lets just hope that they are immune to my rig and don't flip mid game.

I have my Computer, front left base station, additional Index power supply, tactile amps, and dsp boxes. The DSP boxes have euro plugs with adapters that make them wide covering 2 plug outlets. So that's 8 plugs. I flip them on and also have a switched plug on my right rear base station.

I wanted to get the outlet tower model with the switch on top since I turn this on manually before I use my gaming computer, but that model had a very long power cord with thin gauge wire and half the surge suppression.

But as soon as I starting thinking about convenience and the fact that I manually flip two switches on opposite ends of the room, I started looking at this

Last edited:

RCHeliguy

Premium

So now I hear that we have a metal CNC router and CNC plasma cutter coming to the maker space.

Oh hell Yeah!!!!!

Looks like I may be teaching a little Fusion 360 to some members who expressed interest. That could be fun.

Heading over to the maker space this evening to give this vinyl cutting a go and see how it goes.

Oh hell Yeah!!!!!

Looks like I may be teaching a little Fusion 360 to some members who expressed interest. That could be fun.

Heading over to the maker space this evening to give this vinyl cutting a go and see how it goes.

Last edited:

RCHeliguy

Premium

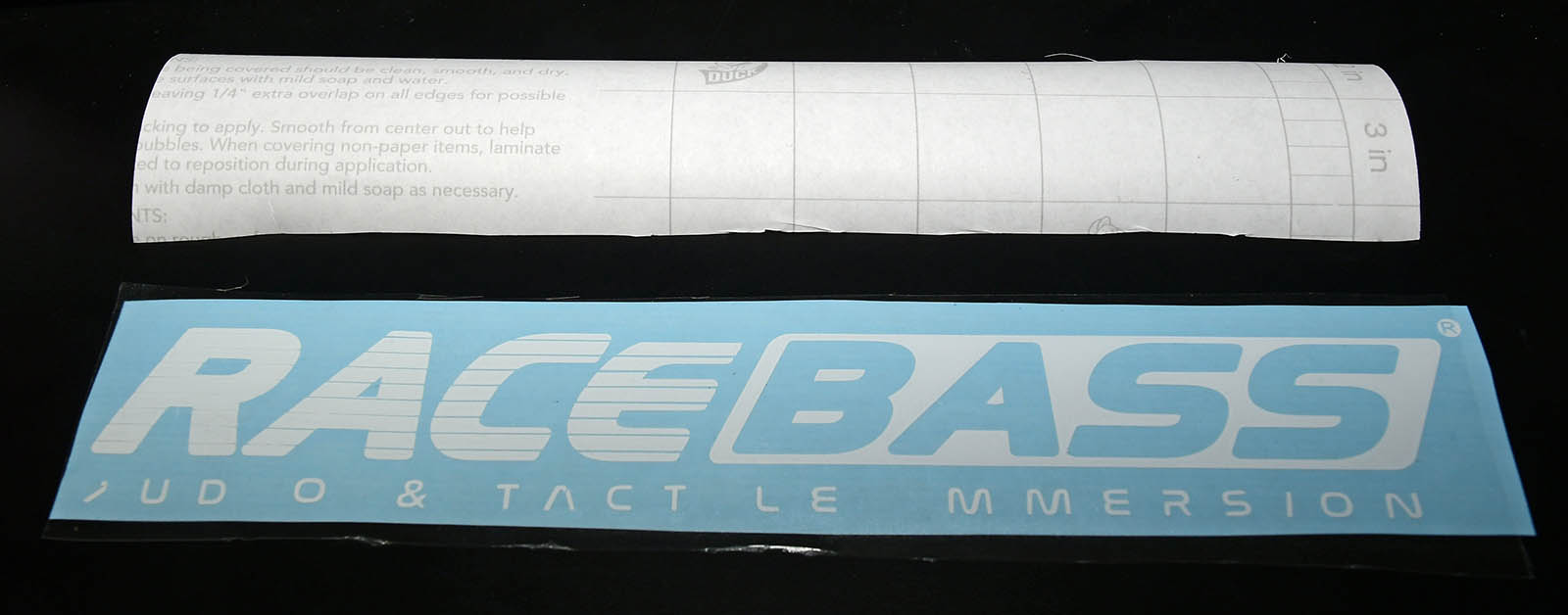

I have 3 attempts cut out of vinyl and some transfer paper. I rounded up and spent $3 on materials there. The vinyl cutter seemed to work like a champ. I used my laptop to print someone else's decal while I was there and it was much more intricate than my logo is. When I left he had it about half weeded out and it looked good.

So I'm optimistic. I haven't started weeding yet. Maybe I'll try with fresh eyes in the morning.

I remembered to take a picture while printing the other person's decal. He had a Macbook and he didn't have a USB-C to USB converter with him.

So I'm optimistic. I haven't started weeding yet. Maybe I'll try with fresh eyes in the morning.

I remembered to take a picture while printing the other person's decal. He had a Macbook and he didn't have a USB-C to USB converter with him.

Last edited:

RCHeliguy

Premium

Started weeding the first one. Seems to be working.

I wasn't paying close enough attention though and I'm missing the top of the E.

That's a good reason to make extras.

I'll finish weeding this one and then try out the transfer paper for practice.

Transfer Paper

Mounted

I think that will work. Now I just need to be careful weeding the next one and I should clean the side of my seat before applying next time.

I think the whole process works fine. I just need a bit more practice weeding.

I wasn't paying close enough attention though and I'm missing the top of the E.

That's a good reason to make extras.

I'll finish weeding this one and then try out the transfer paper for practice.

Transfer Paper

Mounted

I think that will work. Now I just need to be careful weeding the next one and I should clean the side of my seat before applying next time.

I think the whole process works fine. I just need a bit more practice weeding.

Last edited:

RCHeliguy

Premium

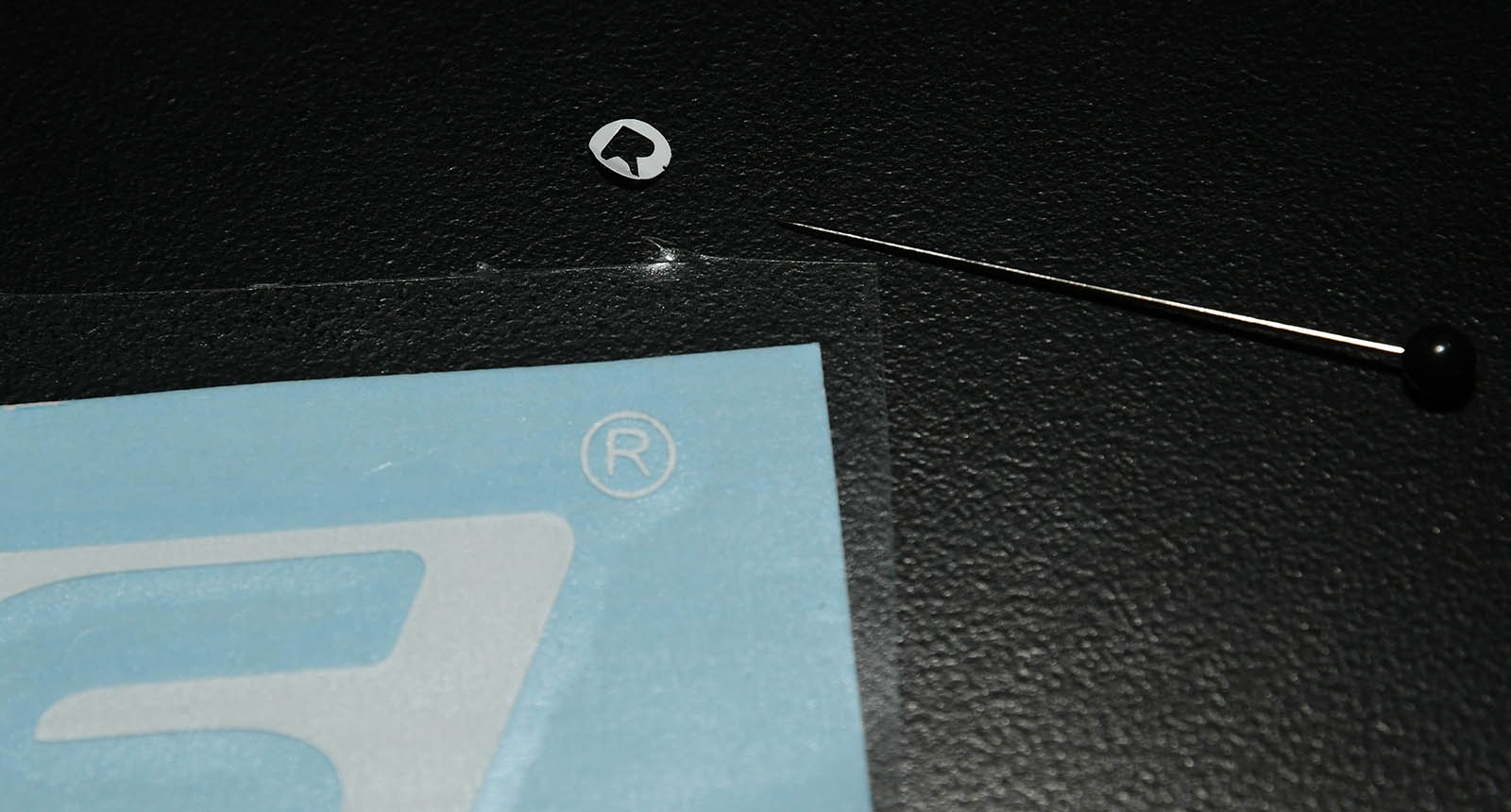

I leveled up my weeding skills on my 2nd try and I even got the Registered Trademark symbol intact!

Phew!

Got it all this time.

Cleaned my seat with Windex first this time and I think I got a perfect application. After carefully rubbing it all onto my seat the transfer paper released without any fanfare.

Phew!

Got it all this time.

Cleaned my seat with Windex first this time and I think I got a perfect application. After carefully rubbing it all onto my seat the transfer paper released without any fanfare.

Looks good. The TM symbol is a good example where sometimes it's easier to weed from the back. Apply the transfer tape first, then remove the scrap from the back side. You can even make 'weeding cuts' in the software so you do all the bigger weeding the normal way, then leave that small area to the last, after you put on the transfer tape. It depends how strong the vinyl sticks to the backing paper vs. the transfer tape. Little pieces like that tend to 'float' sometimes on the packing paper and move around before you can get the transfer tape applied.

Usually it's not a big deal with one-colour designs, as you can sorta eye things up, massage it until it looks ok, and it will be fine. But then, when you go to multi-colour designs.... that's another adventure where the registration of small items in different colours can be really important. It's not difficult, just takes some patience and care.

The biggest issue I ever had is when changing vinyl or materials and getting the cut depth/speed/pressure correct. This is everything to getting a clean cut, without cutting into the backing paper. Looks like the machine and materials you're using are setup and calibrated well.

Usually it's not a big deal with one-colour designs, as you can sorta eye things up, massage it until it looks ok, and it will be fine. But then, when you go to multi-colour designs.... that's another adventure where the registration of small items in different colours can be really important. It's not difficult, just takes some patience and care.

The biggest issue I ever had is when changing vinyl or materials and getting the cut depth/speed/pressure correct. This is everything to getting a clean cut, without cutting into the backing paper. Looks like the machine and materials you're using are setup and calibrated well.

Last edited:

RCHeliguy

Premium

I was thinking about registration for multi-color decals when you showed your Ferrari decal. I assume that you just build the decal from the bottom up until you finally put the whole thing under transfer tape.

I've had a number of people talk about reverse weeding like you mentioned off of the transfer tape.

I'm just happy with how easily this went and now this is just one more thing in my tool bag that I can pull from when I have an idea. I don't have any ideas for a second project at the moment, but I doubt this will be the last time I cut vinyl.

OK, Bridgeport Mill class on Saturday. Then see what project grabs me next

I've had a number of people talk about reverse weeding like you mentioned off of the transfer tape.

I'm just happy with how easily this went and now this is just one more thing in my tool bag that I can pull from when I have an idea. I don't have any ideas for a second project at the moment, but I doubt this will be the last time I cut vinyl.

OK, Bridgeport Mill class on Saturday. Then see what project grabs me next

Latest News

-

Indy 500 Cars That We Would Love To See In Sim RacingThe greatest spectacle in racing has been taking place for over 110 years, and that means plenty...

- Luca Munro

- Updated:

- 7 min read

-

F1 24 PC Specs RevealedWith its launch around the corner, EA Sports and Codemasters have released the F1 24 PC specs...

- Yannik Haustein

- Updated:

- 2 min read

-

IndyCar Secures Game Assets Following Settlement With Motorsport GamesAfter intending to terminate the license in late 2023, IndyCar has reached a settlement with...

- Yannik Haustein

- Updated:

- 2 min read

-

2024 Formula One Monaco Grand PrixOne of the most hotly anticipated Formula One races of the season once again takes place on the...

- Connor Minniss

- Updated:

- 2 min read

-

WATCH: F1 24 Updated Tracks ComparisonF1 24 promises updated versions of no less than four tracks, bringing them up to their current...

- Yannik Haustein

- Updated:

- 1 min read

-

1995 Indianapolis 500: Remembering The Final Pre-Split SpectacleThe 2024 edition of the Indianapolis 500 is just around the corner - a race steeped in history...

- Yannik Haustein

- Updated:

- 9 min read

-

OT Mods: Aussie Supercars Liveries Hit Assetto Corsa CompetizioneAcross sim racing, there are very few Australian Supercars available in first party content, and...

- Angus Martin

- Updated:

- 3 min read