You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mobile Driving/Flying Cockpit with Motion and Tactile ( Build )

RCHeliguy

Premium

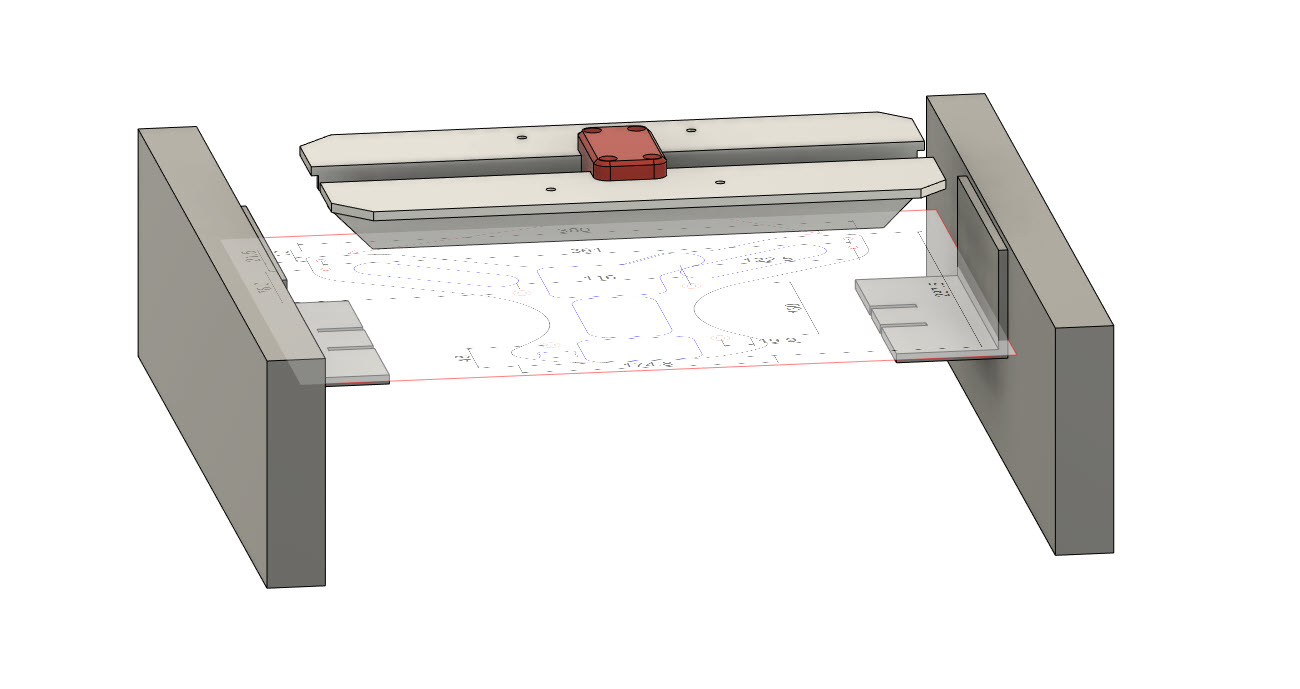

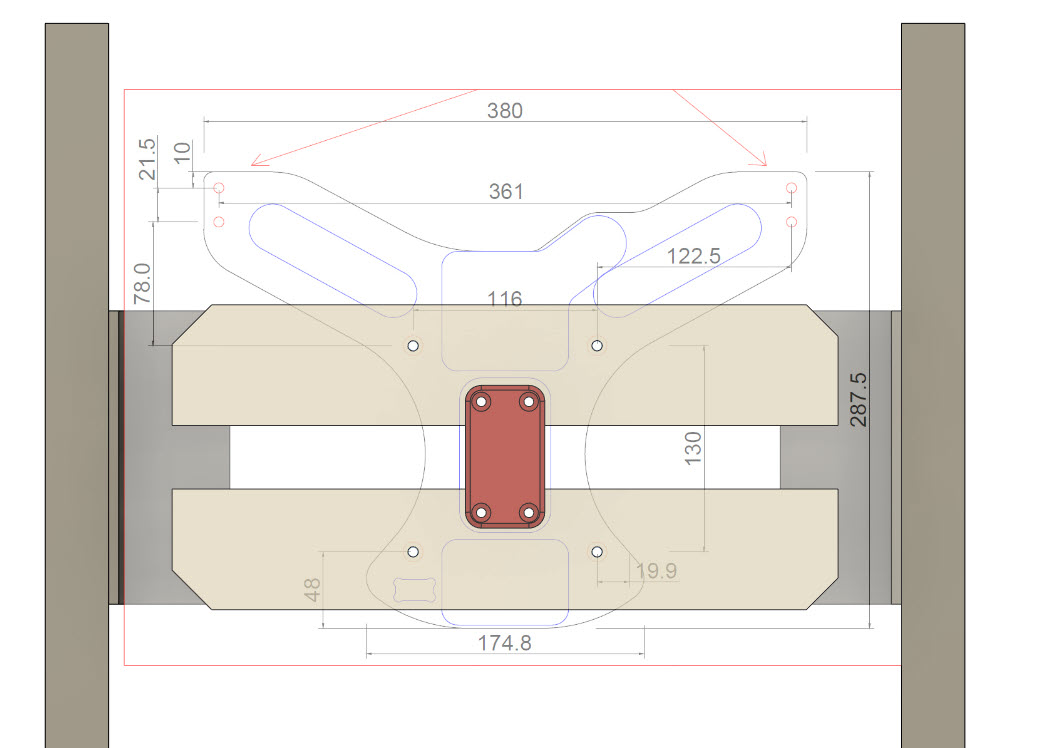

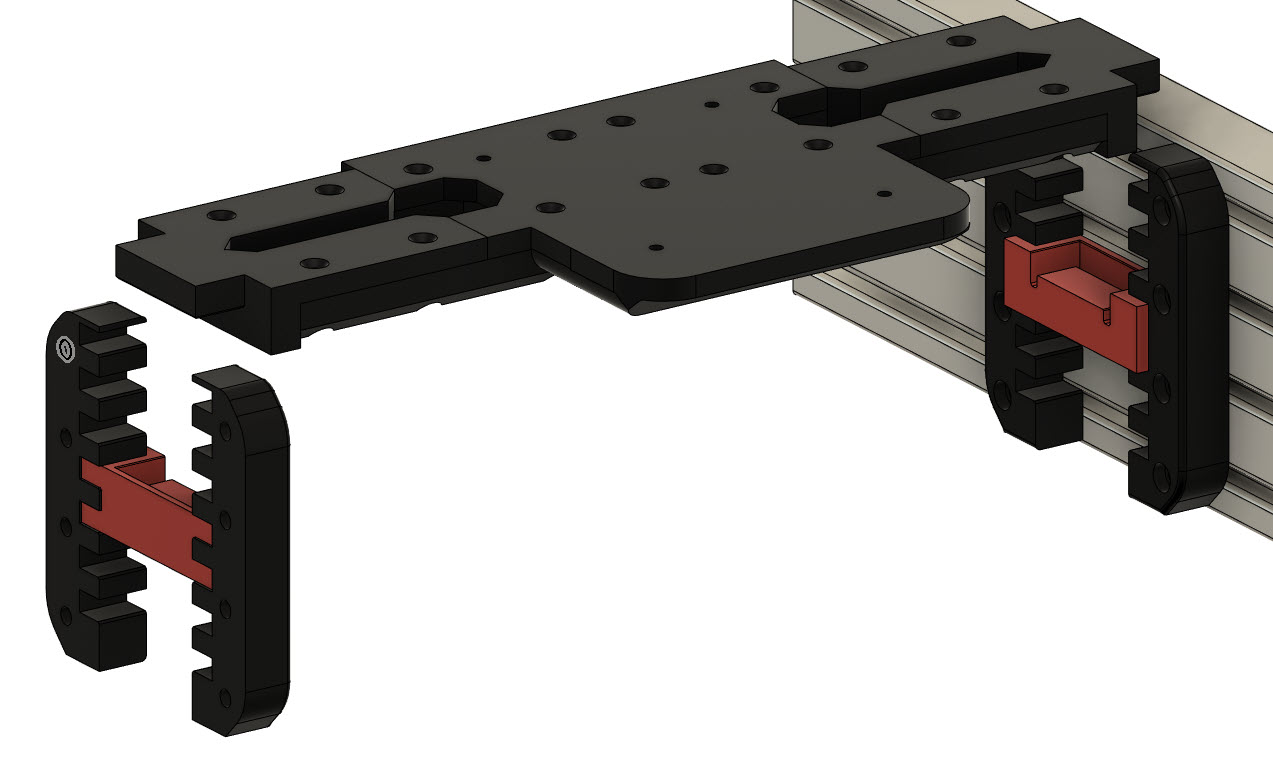

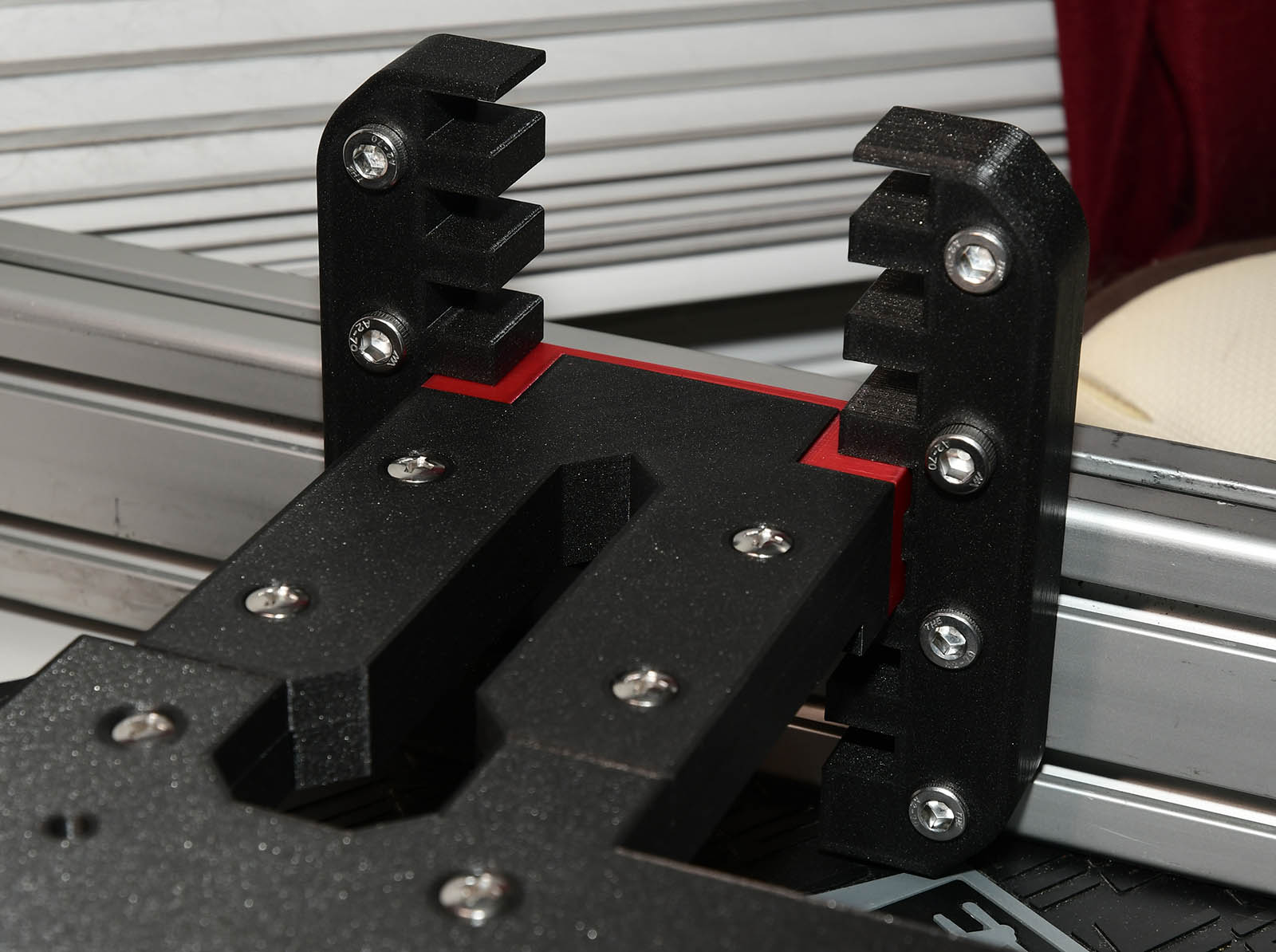

Simplicity  I like this much better.

I like this much better.

If I can get the cuts tight and the alignment right. I should be able to simply drop the pedals in and be done, and then lift them out and be done.

Rather than having fore/aft adjustment on sliders, I can simply slide the side brackets fore/aft with the pedals in place and then secure the brackets in place.

The slots are symmetrical, so the brackets can be flipped, so with a couple sets of holes in the brackets and being able to reverse them, I should be able to get a wide assortment of heights. I just need to measure to the offsets to make sure that I do get additional options and no repetition.

If I can get the cuts tight and the alignment right. I should be able to simply drop the pedals in and be done, and then lift them out and be done.

Rather than having fore/aft adjustment on sliders, I can simply slide the side brackets fore/aft with the pedals in place and then secure the brackets in place.

The slots are symmetrical, so the brackets can be flipped, so with a couple sets of holes in the brackets and being able to reverse them, I should be able to get a wide assortment of heights. I just need to measure to the offsets to make sure that I do get additional options and no repetition.

Last edited:

@RCHeliguy I don't do any flight sim but it's interesting to see the projects your working on, nice job. As I mentioned earlier I got my new vocore display up and running. I also got the first part of my "integrated dash" printed and mounted. Printing off the other side now. Figured I would share my progress with you as you have led me to this wonderful filament  . Once the other box is finished and mounted I am going to determine button layouts and figure out what I want to use for the circuits. I may end up going with a DSD 32 input board or an arduino pro micro not sure yet. Can you recommend any good 4 way joysticks? I am considering using one to replace the need of my keyboard in VR. Don't mind the usb hanging from the vocore, I am going to cable manage that with the electronics for the button boxes once completed. I also used some small 3d printed cable clips to keep it tight on the DD base.

. Once the other box is finished and mounted I am going to determine button layouts and figure out what I want to use for the circuits. I may end up going with a DSD 32 input board or an arduino pro micro not sure yet. Can you recommend any good 4 way joysticks? I am considering using one to replace the need of my keyboard in VR. Don't mind the usb hanging from the vocore, I am going to cable manage that with the electronics for the button boxes once completed. I also used some small 3d printed cable clips to keep it tight on the DD base.

On a side I should probably create a thingaverse account so I can share stl's in the event anyone wants to use the vocore housing. From what I understand I can't share them directly on RD.

On a side I should probably create a thingaverse account so I can share stl's in the event anyone wants to use the vocore housing. From what I understand I can't share them directly on RD.

Attachments

RCHeliguy

Premium

Once the other box is finished and mounted I am going to determine button layouts and figure out what I want to use for the circuits. I may end up going with a DSD 32 input board or an arduino pro micro not sure yet. Can you recommend any good 4 way joysticks? I am considering using one to replace the need of my keyboard in VR. Don't mind the usb hanging from the vocore, I am going to cable manage that with the electronics for the button boxes once completed. I also used some small 3d printed cable clips to keep it tight on the DD base.

On a side I should probably create a thingaverse account so I can share stl's in the event anyone wants to use the vocore housing. From what I understand I can't share them directly on RD.

Glad that filament is working well for you. Your prints look good.

I got a Bodnar 64 input board. It is supported by every software package I've tried and it supports rotaries well. It runs out of the box as 64 switches. You just need to run a simple app to configure which pins you want to use for rotaries. I ended up using almost all of the inputs. It isn't much more than a 32 input board and then there is always room to grow.

I can recommend a few 4 way joysticks.

I'm using a couple of these on my button box now and I'm very happy with them.

9.59€ 55% OFF|22Mm Joystick Schakelaar Momentary 4 Positie 4NO Zelfvergrendelende Lente Wobble Stick Monolever Rocker Kruis Schakelaar HKL FW|Schakelaars| - AliExpress

Smarter Shopping, Better Living! Aliexpress.com

Thingaverse is a good place to put them. Just make sure that you use keywords like simrig and sim racing so people find your stuff. There are some people who are not fans of Thingaverse because of the company that owns it, but it is the biggest out there.

Thanks, I have been tinkering with slicing settings and think I found a happy settings profile for a more finished look. I have also been contemplating the Leo Bodnar board. What are you using to power the leds on your controls? Sorry if I am overlooking something but I don't see a power terminal on leo 64 board. Thanks for the joystick reference I will definitely check those out. In terms of Thingaverse I am not really familiar with the politics of their ownership. It would be nice if you could just share stl's directly on RD however I am not sure if they have a policy against doing so for a reason.

RCHeliguy

Premium

I used a separate 12V power supply.

Amazon.com : 12V 2A Power Supply AC Adapter, AC 100-240V to DC 12 Volt Transformers, 2.1mm X 5.5mm Wall Plug (12 Volt - 2amp - 2pack) : Electronics

Amazon.com : 12V 2A Power Supply AC Adapter, AC 100-240V to DC 12 Volt Transformers, 2.1mm X 5.5mm Wall Plug (12 Volt - 2amp - 2pack) : Electronics

www.amazon.com

RCHeliguy

Premium

I actually have a set of those on hand, however do you have a separate control board where all the 5v pairs terminate to?

The button board runs off of USB power entirely. I just used the 12V or LED lights and my Noctua 200mm fan.

RCHeliguy

Premium

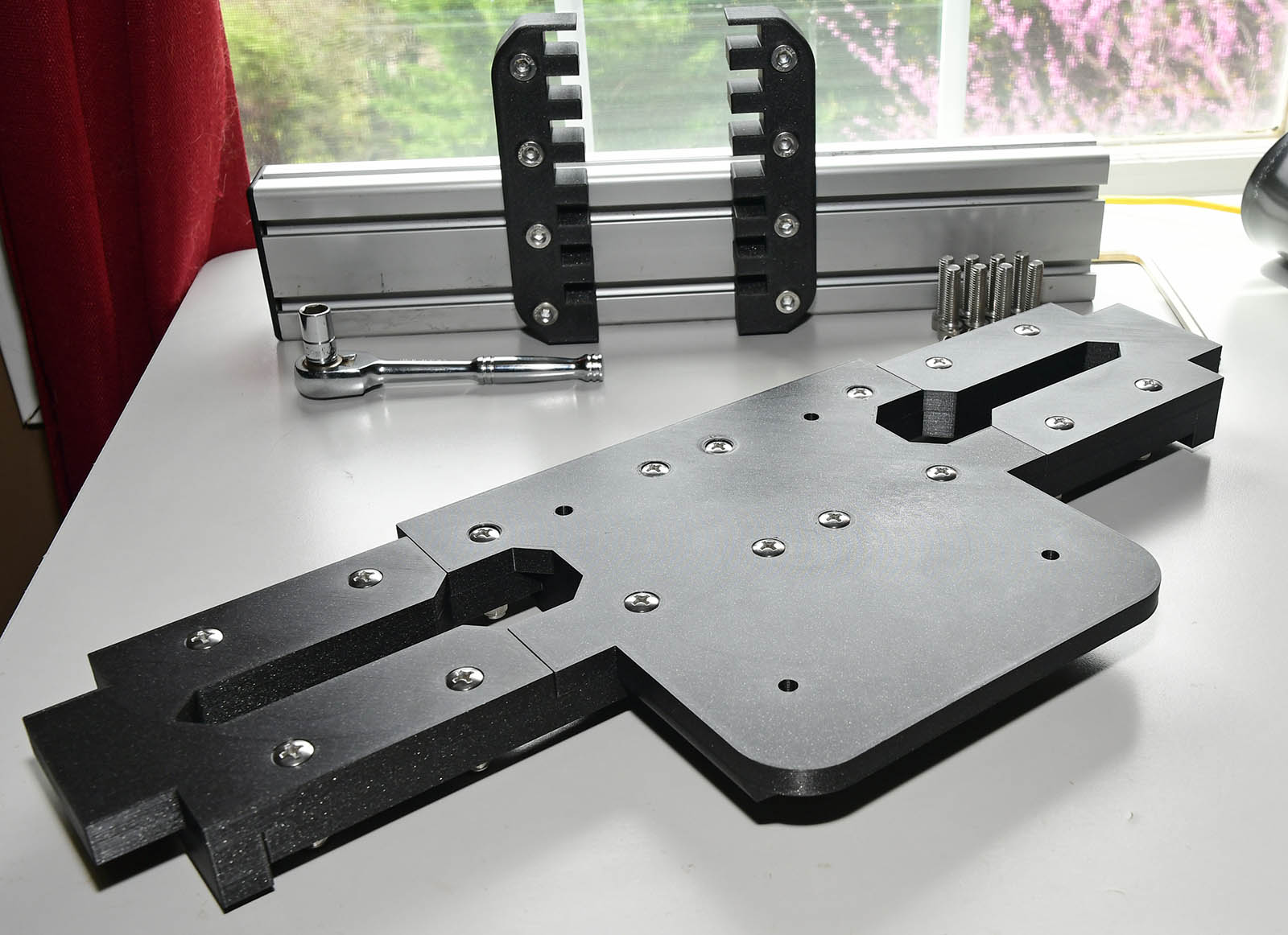

There are two pairs of side bracket holes with a 20mm offset and the brackets are symmetrical so I can flip them. This should give me a pretty wide range of height adjustment and the brackets can slide fore/aft when loosened. The front and rear supports for the flight pedals are also symmetrical.

I'll put UHMW tape on the brackets where they slide on the inside of the frame so they don't scar the frame.

I can print the 3D center while I wait for the M6x35 bolts, additional M6 locknuts and M6 threaded inserts to arrive mid week. I'll probably fabricate the aluminum next weekend.

After this I will have used up the last of my 4x4" angle aluminum, 3x3" angle aluminum and 6" aluminum plate. All I have left is 2"x1.5" rectangular tubing.

Also found these which are interesting if you own Crosswind Pedals.

www.thingiverse.com

www.thingiverse.com

I'm going to print out the Bar140mm pedals and see what I think of them.

I'll put UHMW tape on the brackets where they slide on the inside of the frame so they don't scar the frame.

I can print the 3D center while I wait for the M6x35 bolts, additional M6 locknuts and M6 threaded inserts to arrive mid week. I'll probably fabricate the aluminum next weekend.

After this I will have used up the last of my 4x4" angle aluminum, 3x3" angle aluminum and 6" aluminum plate. All I have left is 2"x1.5" rectangular tubing.

Also found these which are interesting if you own Crosswind Pedals.

MFG Crosswinds Combat Pedals and Bar Pedals by Asherao

A project fueled by aircraft habits.... and a tiny rig. The Combat pedals support "heel-on-floor" type movement, similar to what you see in the F18, F16, B737, and others. The height, and therefore the feel of the braking action, is adjustable. The Bar pedals support helicopters, Mig, and some...

I'm going to print out the Bar140mm pedals and see what I think of them.

Last edited:

RCHeliguy

Premium

RCHeliguy

Premium

Sooooo......

This would be a GREAT application for using a 3D printed buck to create an aluminum sand casting.

Just started looking at aluminum furnaces and sand casting.... Not sure I'll take the deep dive yet, but it has been on my radar for a while.

Then I could just print my parts with minimal fill, epoxy them together sand and prime the surface. Obviously the design would change to be much thinner and minimalist.

This would be a GREAT application for using a 3D printed buck to create an aluminum sand casting.

Just started looking at aluminum furnaces and sand casting.... Not sure I'll take the deep dive yet, but it has been on my radar for a while.

Then I could just print my parts with minimal fill, epoxy them together sand and prime the surface. Obviously the design would change to be much thinner and minimalist.

Amazon.com: USA Cast Master 5 KG DELUXE KIT Propane Furnace with Crucible and Tongs Kiln Smelting Gold Silver Copper Scrap Metal Recycle 5KG KILOGRAM

Shop Castmaster at the Amazon Arts, Crafts & Sewing store. Free Shipping on eligible items. Save on everyday low prices.

www.amazon.com

Last edited:

@RCHeliguy I am sure the angled knurles help give added strength. Also as a side note I have opened a thread with the site administrators and .STL is now a supported attachment file type. So Thingaverse is no longer needed

www.racedepartment.com

www.racedepartment.com

Support for STL attachments

Hello all, I apologize if this is already covered in a different thread, I did a quick search and did not find anything definitive. Is there any technical limitation or perhaps security concern in adding stl's as an attachable file extension? Perhaps this is already possible and I am just...

www.racedepartment.com

www.racedepartment.com

This is most likely true, I think it will be beneficial for those who would like to share the occasional one off with the racing community. As we touched on it another thread I was a bit put off by the need to create another account on an external site. Hopefully this is a feature RD users will find helpful.

RCHeliguy

Premium

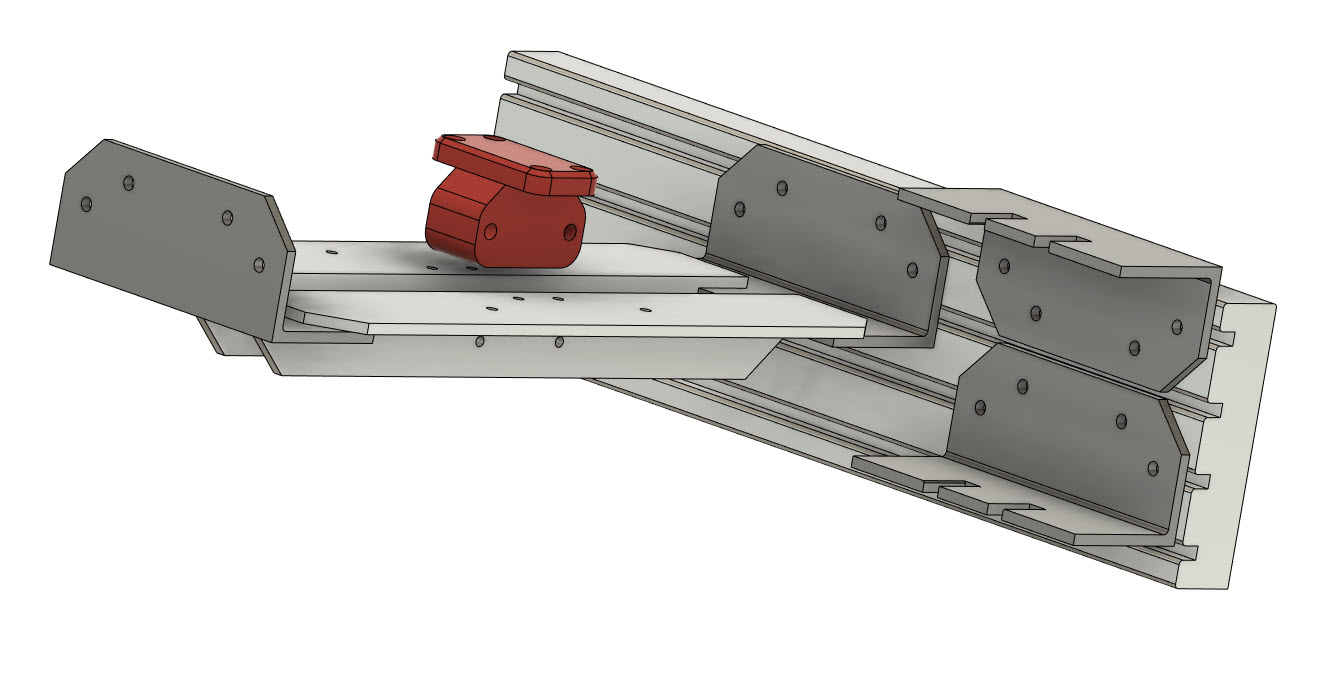

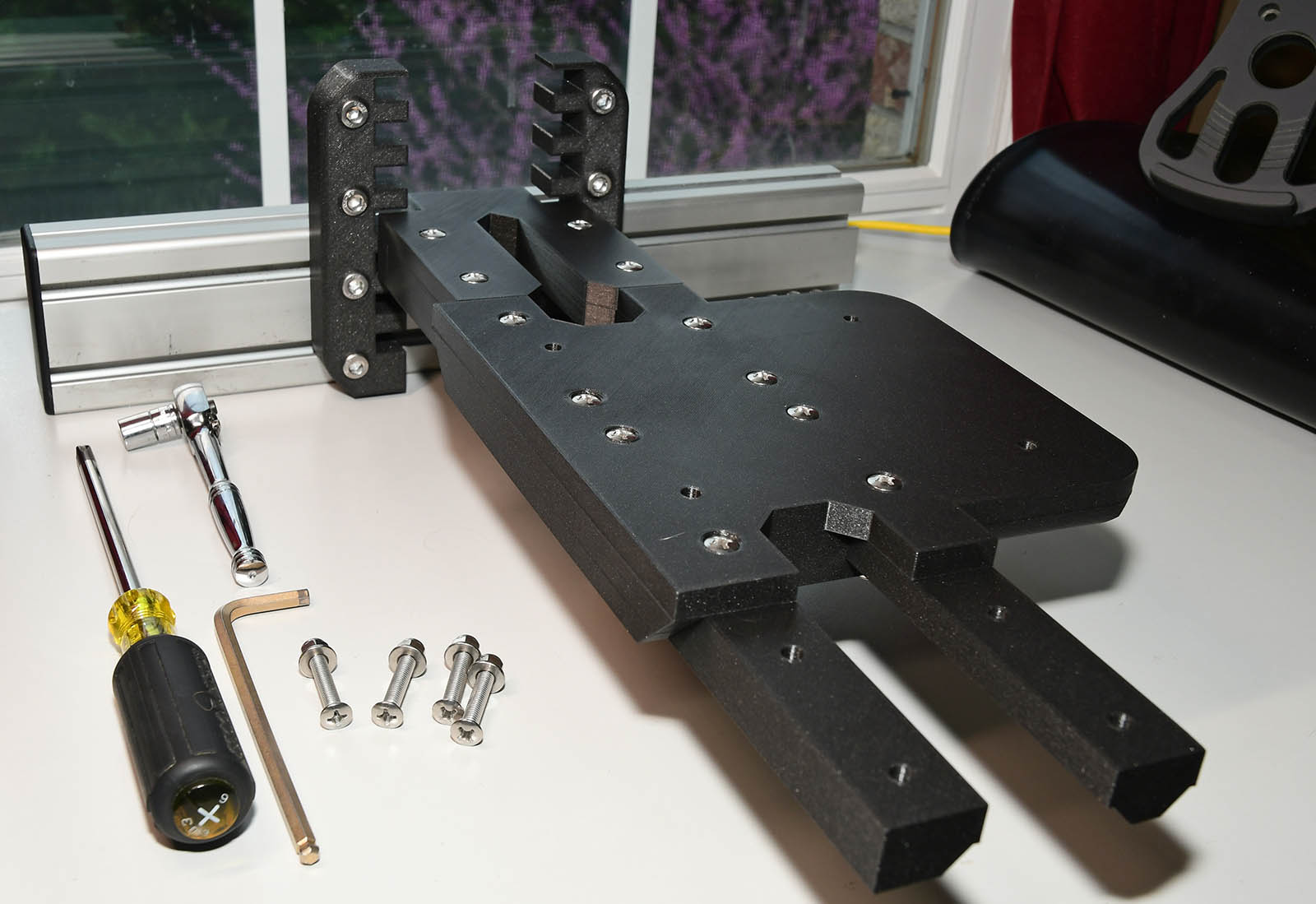

It's times like this when I wish I had two or three 3D printers. But as it turns out that isn't slowing me down. My bevel head M6x35 bolts arrive today, but the Crosswind pedal base I have doesn't have bevels like the drawing I worked off of for the V3 pedals. So I had to order a set of pan head bolts which won't arrive until tomorrow. So having a single printer will only set me back about 1 day.

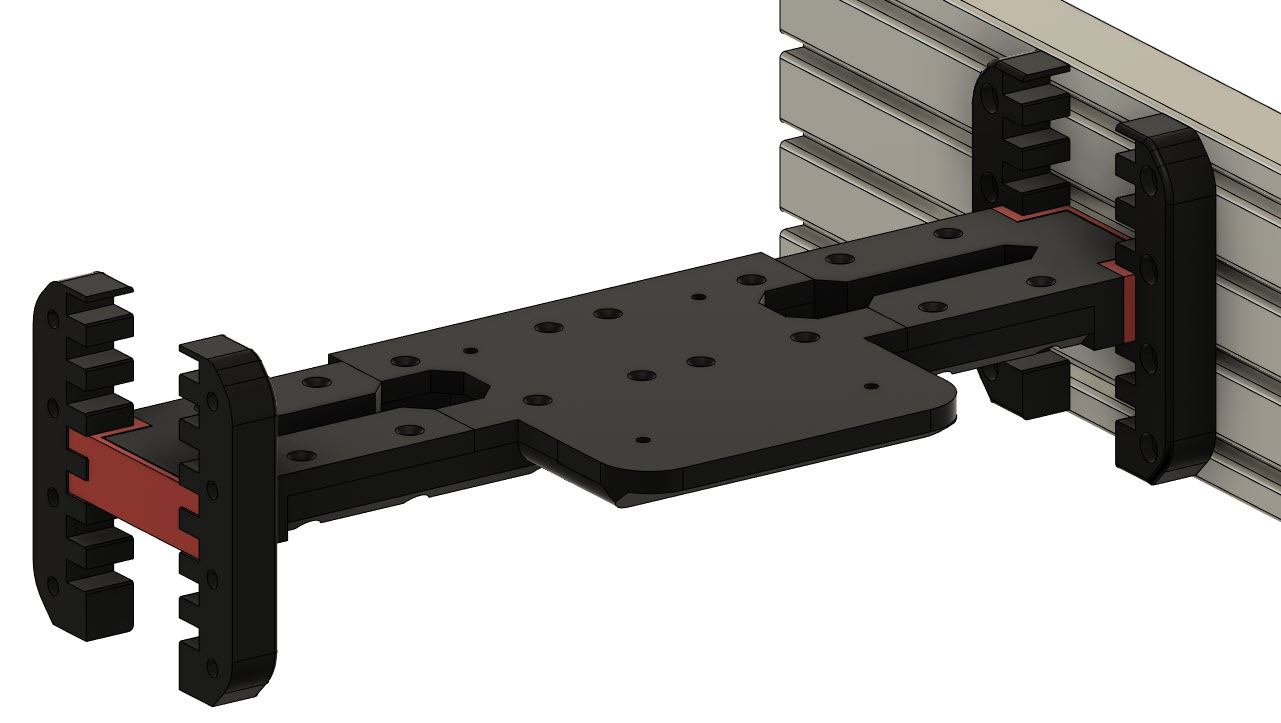

The part fit has been excellent. I'm printing one pair of the side brackets that bolt to the profile right now. Then it will be another day to print the other side supports and finally I'll print the end clips in red. Since they are the only moving parts that I'll move around to adjust height I thought contrast might look good.

This is what I'm aiming for.

Given how well this is fitting together, I'm hopeful that I'll be able to pull the side clips out without much effort. Move them up or down to change height and just drop the pedal deck in place.

The part fit has been excellent. I'm printing one pair of the side brackets that bolt to the profile right now. Then it will be another day to print the other side supports and finally I'll print the end clips in red. Since they are the only moving parts that I'll move around to adjust height I thought contrast might look good.

This is what I'm aiming for.

Given how well this is fitting together, I'm hopeful that I'll be able to pull the side clips out without much effort. Move them up or down to change height and just drop the pedal deck in place.

Last edited:

RCHeliguy

Premium

The top left arm will be done printing in about 5 hours.

Then I'm going to print the red clips which should finish later this evening.

The pan head bolts that will secure the flight pedals to this mount are out for delivery now.

Finally the left pair of brackets will print overnight and tomorrow morning I will be able to put this in my rig

My next post will be Friday morning with this mounted to my rig.

In other news the new Sprint pedal faces from HRS in Australia are supposed to arrive next Thursday and the Crosswind damper is still scheduled for next Monday.

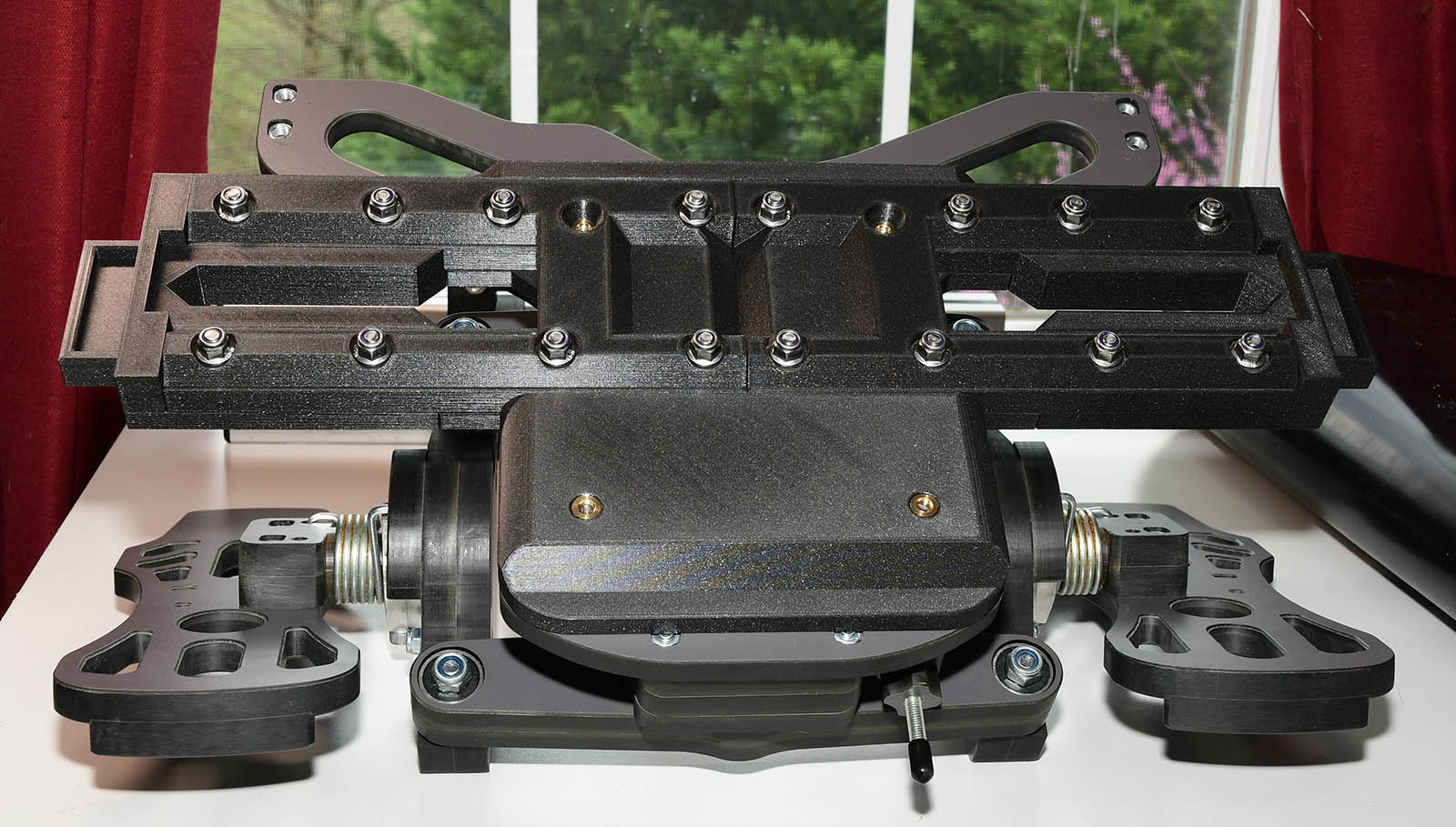

The 4 bolts across the center have to be flush because the pedal deck is directly or partially over them. I've modified my drawings with deeper bevels, but I used my soldering iron to push them deeper since the center section uses about 25% of a 1kg spool.

I'm using lock nuts to hold the arms together and inserts to hold the flight pedal base down.

Then I'm going to print the red clips which should finish later this evening.

The pan head bolts that will secure the flight pedals to this mount are out for delivery now.

Finally the left pair of brackets will print overnight and tomorrow morning I will be able to put this in my rig

My next post will be Friday morning with this mounted to my rig.

In other news the new Sprint pedal faces from HRS in Australia are supposed to arrive next Thursday and the Crosswind damper is still scheduled for next Monday.

The 4 bolts across the center have to be flush because the pedal deck is directly or partially over them. I've modified my drawings with deeper bevels, but I used my soldering iron to push them deeper since the center section uses about 25% of a 1kg spool.

I'm using lock nuts to hold the arms together and inserts to hold the flight pedal base down.

Last edited:

RCHeliguy

Premium

This is really close and technically this does work.

However I printed with supports to a lip that isn't necessary and I had to chisel away material to get the clips to fit.

So I'm redesigning the clips with 3 changes.

I also decided that the brackets are too long. I need space to route cables under them and I'll never drop my pedals all the way down. At some point I'm going to print shorter brackets.

I think that will be it. I'll test fit this in a few hours with the existing clips when the other pair of brackets are finished in 4 hours and if that all goes well, I'll reprint new clips and now and at some point print new brackets.

However I printed with supports to a lip that isn't necessary and I had to chisel away material to get the clips to fit.

So I'm redesigning the clips with 3 changes.

- I removed the overhang so it no longer needs supports.

- There is a lip at the bottom and indentation at the top so you can easily grab the clips with your fingers to pull them out to change height.

- I rounded the edges that insert into the bracket slots to make it easier to start.

I also decided that the brackets are too long. I need space to route cables under them and I'll never drop my pedals all the way down. At some point I'm going to print shorter brackets.

I think that will be it. I'll test fit this in a few hours with the existing clips when the other pair of brackets are finished in 4 hours and if that all goes well, I'll reprint new clips and now and at some point print new brackets.

Last edited:

Latest News

-

F1 24 Preview: First Impressions, Handling & New Game ModesThe wait for Formula One fans is almost over, as F1 24 is going to release next week. We got to...

- Yannik Haustein

- Updated:

- 6 min read

-

IMMERSION Modding Group Adds 9 Scenarios To 1986 F1 Season PackAfter exploring some of its possibilities, the IMMERSION Modding Group XML Selector now gets...

- Yannik Haustein

- Updated:

- 2 min read

-

Drag & Drift Races Return In New Need for Speed Unbound UpdateNeed For Speed Unbound has has added two classic modes from the series' history, as well as two...

- Luca Munro

- Updated:

- 2 min read

-

OverTake Goes Brickyard: Join Our OT IndyCar 500 (km) In rF2 For FreeIt is race week for the Biggest Spectacle in Racing, so our Racing Club is hosting its own...

- Yannik Haustein

- Updated:

- 2 min read

-

Max Verstappen's Busy Double-Victory WeekendMax Verstappen won the 2024 Formula One Emilia Romagna Grand Prix at Imola, but the Dutchman is...

- Yannik Haustein

- Updated:

- 3 min read

-

BMW M8 GTE Completes Trio Of New RaceRoom Cars (Updated With Patch Notes)After announcing the M2 CS Racing and the M4 GT4, RaceRoom unveiled the BMW M8 GTE to be the...

- Yannik Haustein

- Updated:

- 2 min read

-

Monster Jam Showdown: 'Just In Monster Jam' Trailer Shows New FeaturesThe team at Milestone have released the newest trailer for Monster Jam Showdown. From off-road...

- Connor Minniss

- Updated:

- 2 min read