I had heard of the 'ironing' technique, but I was not familiar with the 'painting' term, I'm assuming this is in reference to supports? I also noticed they refer to 'seam painting' too. I guess it's just a general term to mark an area where you want something manually applied?1. Painting where you want

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking at 3D printers...

- Thread starter RCHeliguy

- Start date

RCHeliguy

Premium

I had heard of the 'ironing' technique, but I was not familiar with the 'painting' term, I'm assuming this is in reference to supports? I also noticed they refer to 'seam painting' too. I guess it's just a general term to mark an area where you want something manually applied?

Yes, you paint where you want a support in one color and you can also paint where you want to make sure it doesn't put a support. So you could have it automatically generate supports except where you don't want it, or put them only where you specify.

Paint here.

Slice

The ironing will make very narrow passes at a thin layer height to give you a smooth flat surface.

This is sliced without ironing. Sometimes there are small holes or gaps in the letter surfaces printing this way.

With ironing on the top layer only, the nozzle makes overlapping passes that create a smoother finish. For the letters on my labels it worked very well.

There can be a bit more stringing, but I haven't found it to be too bad and I end up cleaning the lettering with an X-Acto knife anyway.

Last edited:

I've been interested in 3D printers for years but never actually bought one and went for it. Think I am going to get one now and I am trying to decide if I should just spend the extra money now and go for a Prusa like you. Your button box design is excellent and to be honest, I wanted to copy major elements of it so thank you for sharing it. I wanted to quickly check in with you to see if you still feel like the Prusa was the way to go. Seems like they are a well designed product that is widely recommended but it sure is not the cheapest way into the hobby. I had considered wanting to do a formula or GT style rim at some point which seems like it would be too large to do as one piece for the Prusa but maybe that is just a foolish idea on my part and I don't know enough yet.

It also seems one of the advantages of the Prusa is the ability to print in different materials pretty easily. Do you really print in anything other then PLA or is that more of a feature that does not really get used but to try stuff out?

Thanks for the guidance and for sharing your thoughts and plans.

It also seems one of the advantages of the Prusa is the ability to print in different materials pretty easily. Do you really print in anything other then PLA or is that more of a feature that does not really get used but to try stuff out?

Thanks for the guidance and for sharing your thoughts and plans.

RCHeliguy

Premium

I'm still tickled with my Prusa. It just keeps going and going flawlessly.

I've printed some things in PETG using the Prusa profiles for it and it prints well too.

So far any Prusa filament using PrusaSlicer and PrusaSlicer profiles has worked great. I've used a pile of different colors of PLA and a couple of PETG so far. I'm not quite ready to try PC yet.

I would suggest making sure to get both the smooth print surface and the textured surface and you the glue sticks that they recommend. I use glue sticks for PETG. The textured surface looks great.

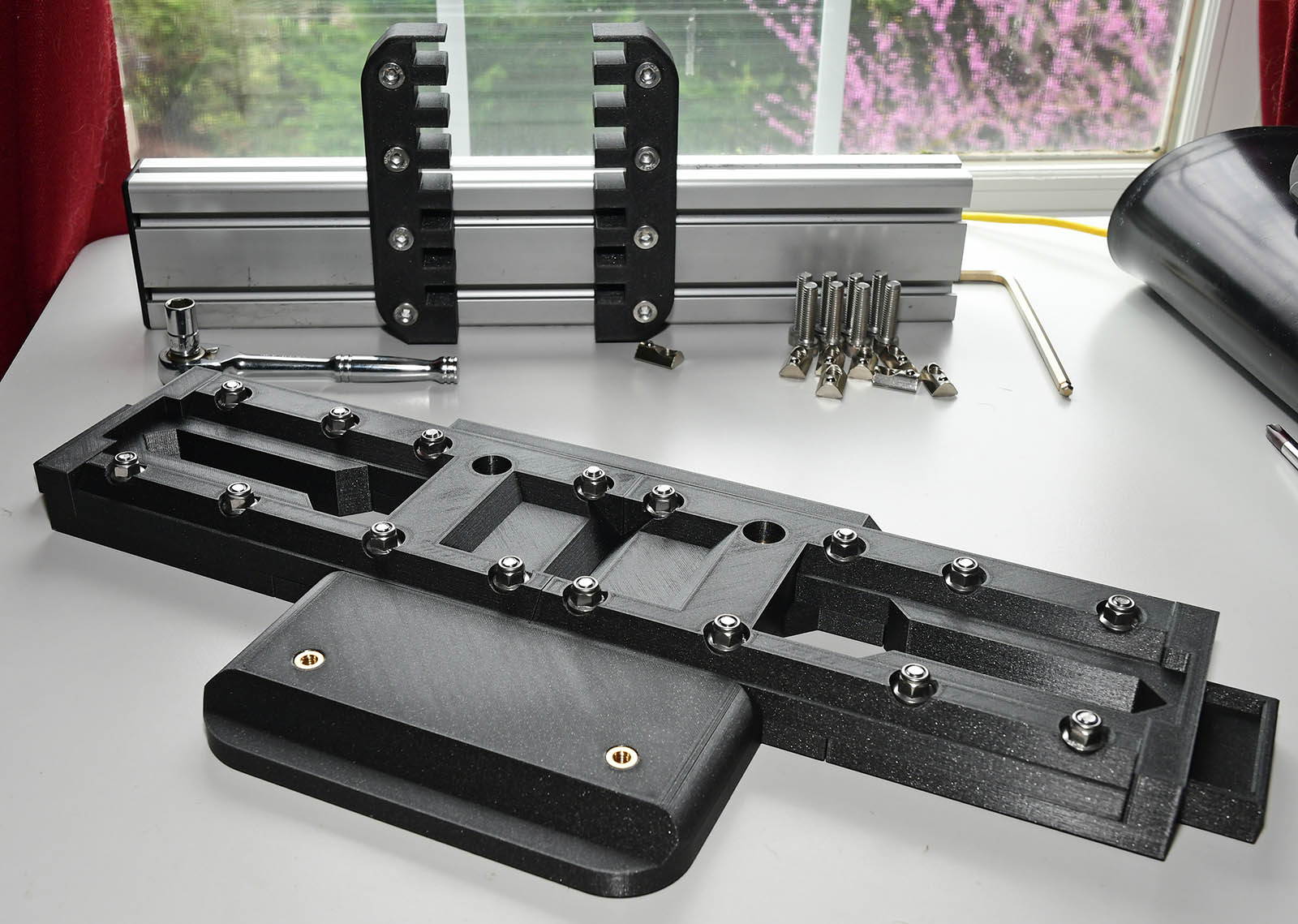

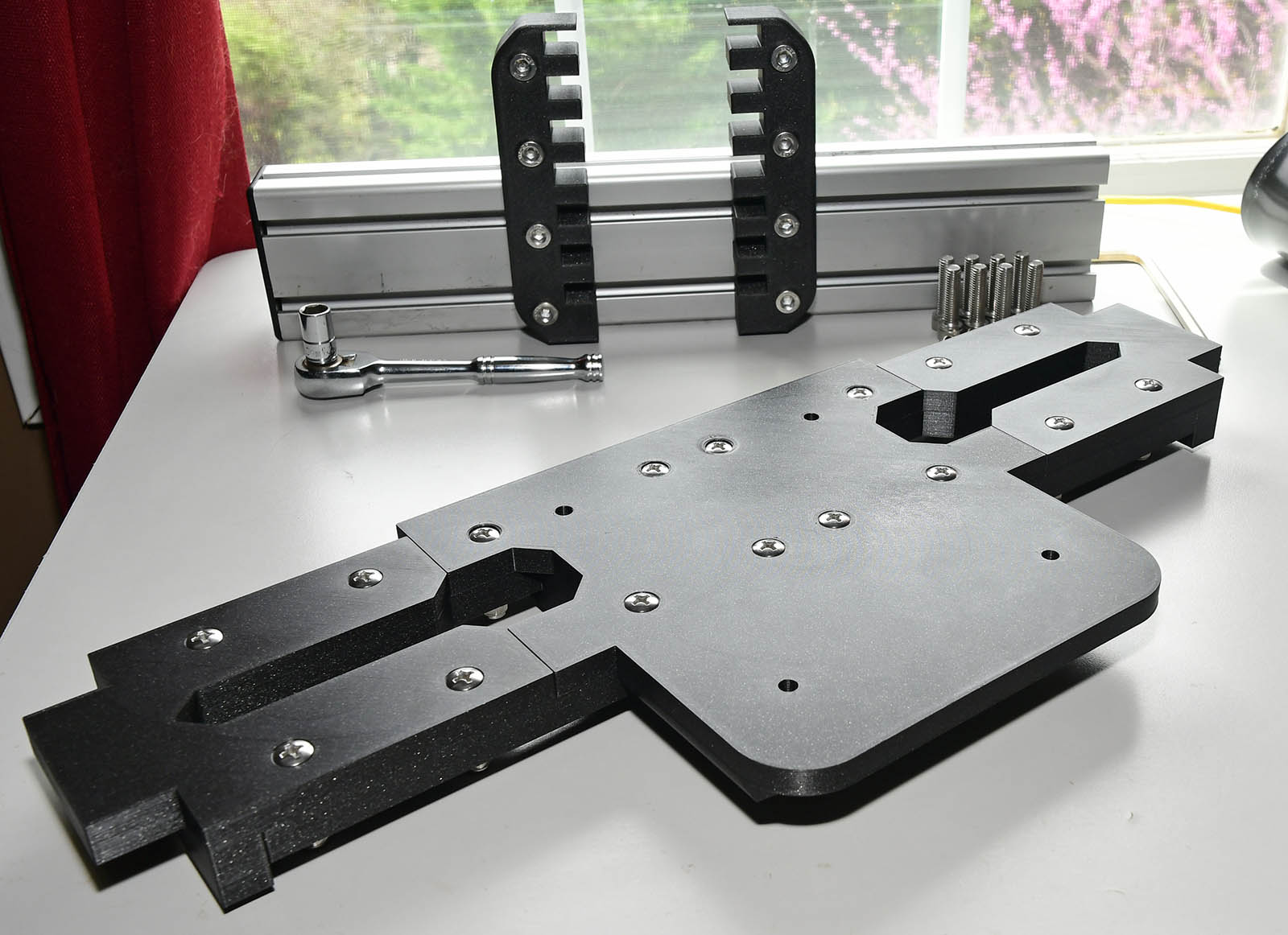

I keep my printer very busy. It's been printing all week non-stop to make my new adjustable flight pedal deck. I'm using a full 1kg spool of filament on this print which is not typical, but for something that will take this much stress I think it makes sense to use a bit more filament.

This is printed using the smooth bed because PLA tends to stay flat on very large prints with the smooth bed and the center section nearly filled the entire bed.

I've printed some things in PETG using the Prusa profiles for it and it prints well too.

So far any Prusa filament using PrusaSlicer and PrusaSlicer profiles has worked great. I've used a pile of different colors of PLA and a couple of PETG so far. I'm not quite ready to try PC yet.

I would suggest making sure to get both the smooth print surface and the textured surface and you the glue sticks that they recommend. I use glue sticks for PETG. The textured surface looks great.

I keep my printer very busy. It's been printing all week non-stop to make my new adjustable flight pedal deck. I'm using a full 1kg spool of filament on this print which is not typical, but for something that will take this much stress I think it makes sense to use a bit more filament.

This is printed using the smooth bed because PLA tends to stay flat on very large prints with the smooth bed and the center section nearly filled the entire bed.

Last edited:

You can either spend a lot of money on a professionally built computer for business use cases, or you can get down in the weeds, put in the effort, and build one yourself from a kit or from scratch also check cheap sublimation printer reviews.

That Tiko, like many other "industrially designed" printers on the market, makes certain fundamental sacrifices in the frame and mechanics that you might not notice unless you understand the design tradeoffs made by other printers.

Laser cut plywood is inexpensive and allows you to repair a damaged component without having to contact the original vendor. Exposed wires, which I despise and wrap, are simple to access and alter. Even if the vendor goes out of business, I can repair my printer from parts if necessary. If something goes wrong with the Tiko, M3D, or MakerBot, you're not going to be able to patch it and keep going.

In my living room, I put my kit-bashed i3v front and center. I can assure you that I am prouder of it than any printer I might purchase.

That Tiko, like many other "industrially designed" printers on the market, makes certain fundamental sacrifices in the frame and mechanics that you might not notice unless you understand the design tradeoffs made by other printers.

Laser cut plywood is inexpensive and allows you to repair a damaged component without having to contact the original vendor. Exposed wires, which I despise and wrap, are simple to access and alter. Even if the vendor goes out of business, I can repair my printer from parts if necessary. If something goes wrong with the Tiko, M3D, or MakerBot, you're not going to be able to patch it and keep going.

In my living room, I put my kit-bashed i3v front and center. I can assure you that I am prouder of it than any printer I might purchase.

Last edited:

RCHeliguy

Premium

That's great! There is a lot of personal satisfaction that comes from doing things yourself and learning how something works. You are correct that I'm not proud of my 3D printer like you are. I'm merely satisfied with a purchase. My printer currently sits tucked away in an unused bedroom and I only visit it when I need something from it although I keep it very busy.

We all have different priorities and should do whatever gives each of us the most satisfaction.

We all have different priorities and should do whatever gives each of us the most satisfaction.

I've been interested in 3D printers for years but never actually bought one and went for it. Think I am going to get one now and I am trying to decide if I should just spend the extra money now and go for a Prusa like you.

I have a Prusa Mini. I don't "love" the Mini or 3D printers in general, but mine has seen a fair amount of use.

Many people buy a 3D printer, pump out a few test parts (the usual benchy, etc.), and then it just gathers dust. The difference between those folks and people who get a lot out of a printer is the degree to which one invests the time and effort into learning to do 3D design. Learning to use Tinkercad, for example, is easy. For relatively-simple structural projects (as opposed to character models, etc.) it is satisfactory and all you need. Stay in the hobby with ever more elaborate projects, though, and you will want a more professional CAD program.

Another expectation that you should go into understanding very well is that print times are ridiculously long! Even a tiny part will take an hour, modest-sized parts will take 8 hours or longer, and large parts can take a day or more. The good news is that once a print starts off properly (it's wise to watch that first layer), the rest of the print usually completes just fine without issue.

Another fact of life: The long print times can make a project time consuming due to trial-and-error. I almost always have to redo designs since something almost always doesn't fit quite right, etc. My discards pile is much larger than my keepers!

Then there's the size of the printer to think about. I bought the Mini since I hadn't used one before, I didn't want to invest much more, and it was big enough for the project I had in mind at the time. However, my current project pushes it right to its bed-size limits, so I partly wish I had gone with the Prusa I3 or a clone with a larger bed.

Another thing to think about is the types of filament that you will be using. I print 50/50 PLA and PETG, and the Mini handles these just fine. PLA is easiest and most reliable, and it usually produces the best looking prints, but it's a relatively stiff and fragile material that doesn't handle stress or impacts well. PETG is just a little harder to print, with potential problems showing up such as raised corners on bed-filling prints, but it's a much tougher material that's far better for structural parts that must bear loads.

On the other hand, my attempt at using "flex" material was an utter failure (the i3 would handle this better), and higher-temperature materials usually requires an enclosure. My opinion is that on a machine like the Mini and lower-cost options, one needs to be satisfied with PLA and PETG.

Another important consideration is bed adhesion. Prusa's printers have excellent, magnetically-attached, bed options: Spring steel coated with a smooth, medium or rough surface for different materials or surface finishes. I have the smooth and rough beds (typically used for PLA and PETG, respectively). Printers with beds made with materials like glass will have significantly greater issues with bed adhesion.

Finally, one has to decide if the level of documentation, support, firmware reliability, general ecosystem, etc., is worth a premium over the many clones and budget printers. Many low-cost printers will have cut corners and will eventually drive one towards upgrades, or they will be extra-noisy, etc. In my case, going with the Prusa was well worth it.

3D printing is a geeky hobby to get into. But if you have the need and patience for it, it can be a source of inspiration and a very useful tool.

Alright, I think I have decided on the Prusa MK3s+ as well. I like the solid open source platform with the integration between the same company making the hardware, firmware, and slicer. I have started to take the approach that I would rather buy one real quality tool then a series of cheapies, I'm not sure that strategy fits with 3D printers right now, however, I could see myself getting a Creality printer, then upgrading part after part and ending up with something completely different and an additional box of parts.

Might be a poor decision, but I was thanking of getting the kit instead of the preinstalled setup. Sounds like it takes people 8-10 hours to build their first one. Thing is, I don't know hardly anything about these and I'm not longer in school where I could take a class, so I kind of figured building it would be a good learning experience where I would get a better understanding of how everything works and goes together. Plus, if I then decide to sell it at some point, I won't lose much since I paid less to begin with and added some value assembling it.

Is this foolish to try and build the kit with 0 experience?

I am currently in the middle of the same decision/learning experiences/mistake with a kit car build where I thought the best way to learn how to work on a car was to build my own from parts. I'm a stubborn dumb SOB that likes to figure something out myself. Got most of it together, but the wiring... um... to be continued.

I also noticed the Bear upgrade for the Prusa printers and I am now a sucker for aluminum extrusion, so it caught my eye. Had me wondering if I should just order those piece now and build it that way to begin with or if that was just eye candy mostly.

Also spotted Caribou printers which seem to be upgraded MK3S printers to me. Reminds me of how my dad approached building anything. "What do you got there, 8 MM rails, lets go ahead an bump that up to 10MM. Is it needed, who knows but it should be stronger. Lets throw more power at it and make it taller while were at it." Got to be honest, I love me some "more better" too. Any actual need behind any of this or would you recommend any changes to the MK3S+? Seems like they run the Prusas in print farms and they have shown to be pretty durable machines as is so maybe it is all "extra" and I don't need to concern myself with it now.

Thanks again.

Might be a poor decision, but I was thanking of getting the kit instead of the preinstalled setup. Sounds like it takes people 8-10 hours to build their first one. Thing is, I don't know hardly anything about these and I'm not longer in school where I could take a class, so I kind of figured building it would be a good learning experience where I would get a better understanding of how everything works and goes together. Plus, if I then decide to sell it at some point, I won't lose much since I paid less to begin with and added some value assembling it.

Is this foolish to try and build the kit with 0 experience?

I am currently in the middle of the same decision/learning experiences/mistake with a kit car build where I thought the best way to learn how to work on a car was to build my own from parts. I'm a stubborn dumb SOB that likes to figure something out myself. Got most of it together, but the wiring... um... to be continued.

I also noticed the Bear upgrade for the Prusa printers and I am now a sucker for aluminum extrusion, so it caught my eye. Had me wondering if I should just order those piece now and build it that way to begin with or if that was just eye candy mostly.

Also spotted Caribou printers which seem to be upgraded MK3S printers to me. Reminds me of how my dad approached building anything. "What do you got there, 8 MM rails, lets go ahead an bump that up to 10MM. Is it needed, who knows but it should be stronger. Lets throw more power at it and make it taller while were at it." Got to be honest, I love me some "more better" too. Any actual need behind any of this or would you recommend any changes to the MK3S+? Seems like they run the Prusas in print farms and they have shown to be pretty durable machines as is so maybe it is all "extra" and I don't need to concern myself with it now.

Thanks again.

RCHeliguy

Premium

The build will take 6-8 hours.

As long as you are careful the instructions are well documented.

Be patient and verify everything before you screw anything together.

There are a few places to be careful of mostly in terms of getting the frame in perfect alignment that would seem critical to print quality.

I've had nothing but great prints with mine. I've spent all my time in Fusion 360 learning how to design the things I want and almost zero time messing with my 3D printer.

As long as you are careful the instructions are well documented.

Be patient and verify everything before you screw anything together.

There are a few places to be careful of mostly in terms of getting the frame in perfect alignment that would seem critical to print quality.

I've had nothing but great prints with mine. I've spent all my time in Fusion 360 learning how to design the things I want and almost zero time messing with my 3D printer.

Last edited:

If you haven't already ordered it, I would seriously think about a Prusa Mini+ if it's your first 3D printer. I looked long and hard at the MK3S+ but eventually decided on the Mini+ as my introduction to the hobby and couldn't be more pleased. The build volume may be smaller than the MK3S+ but that hasn't caused me any problems so far and you can always split the model if absolutely necessary. I bought the ready-made printer (still some assembly required) and, after the initial calibration, haven't had a single print that hasn't been perfect. It may be less than half the price of the MK3S+ but it's probably equally as good at what it's designed to do.Alright, I think I have decided on the Prusa MK3s+ as well.

RCHeliguy

Premium

I have heard a few people express regret for not getting a larger build volume to begin with. I know I designed a number of things as large as I could print on my surface. Some I already broke into smaller parts, but a few would have been difficult to split up.

However, the majority of my prints would fit easily on a mini and I'm not suggesting it isn't a good option.

However, the majority of my prints would fit easily on a mini and I'm not suggesting it isn't a good option.

D

Deleted member 1451080

-

Deleted member 1451080

Deleted

Last edited by a moderator:

Do you happen to know if the Mini+ is big enough to print the parts for the DIY SFX100 motion system? The build size on the Mini is not that much smaller then the MK3S+ but I am not sure how big you need for most things.If you haven't already ordered it, I would seriously think about a Prusa Mini+ if it's your first 3D printer. I looked long and hard at the MK3S+ but eventually decided on the Mini+ as my introduction to the hobby and couldn't be more pleased. The build volume may be smaller than the MK3S+ but that hasn't caused me any problems so far and you can always split the model if absolutely necessary. I bought the ready-made printer (still some assembly required) and, after the initial calibration, haven't had a single print that hasn't been perfect. It may be less than half the price of the MK3S+ but it's probably equally as good at what it's designed to do.

On the other end, it is no real secret Prusa has been working on an XL model. I think they are planning on showcasing it at some Dubai show this year with an automation system or some form. They also made a comments on having two other printers coming in 2021 but I don't really know what they would be. Sounds like they have been working on vertical integration and making more of their own parts. I am guessing there will be new boards coming which they will label as new printers for the MK4? and Mini2? I don't really know. All I know is I have a problem where I always seem to be wanting to wait for that shiny new toy on the horizon.

Last edited:

Sorry, I’m not familiar with the project. If it helps, the Mini+ has a maximum build volume of 180x180x180mm.Do you happen to know if the Mini+ is big enough to print the parts for the DIY SFX100 motion system?

I finally placed an order for a Prusa Mk3S+ kit. I'm super excited and am really looking forward to the actual printer build. I know a lot of people decide to buy the pre assembled version directly from Prusa, but I think the build will be a great way for me to learn how everything works. Going to take a day off work to build it. Man, how dorky is that? I'm taking and looking forward to a vacation day to build something, so I can build other things. Got a pretty long list of things I already want to print. Should have enough to keep it busy for at least a couple months.

RasmusP

Premium

Enjoy! Took me 8 hours straight to built it. I didn't rush it, but I had a prebuilt next to me and had taken the printing unit apart a few times alreadyI finally placed an order for a Prusa Mk3S+ kit. I'm super excited and am really looking forward to the actual printer build. I know a lot of people decide to buy the pre assembled version directly from Prusa, but I think the build will be a great way for me to learn how everything works. Going to take a day off work to build it. Man, how dorky is that? I'm taking and looking forward to a vacation day to build something, so I can build other things. Got a pretty long list of things I already want to print. Should have enough to keep it busy for at least a couple months.

But it's fun when it prints for the first time!

Latest News

-

VR Will Hit EA SPORTS WRC In Beta Form 30th AprilVR support will arrive for EA SPORTS WRC next week, initially in beta form, as features...

- Thomas Harrison-Lord

- Updated:

- 3 min read

-

New RaceRoom Drift Content and Community Cup Final At Tuning World BodenseAn in-person final for a RaceRoom community sim racing competition will be held at...

- Thomas Harrison-Lord

- Updated:

- 2 min read

-

Fanatec Renews F1 Partnership Amidst Investment PitchesOfficial Formula 1 branded sim racing continue will continue to be produced by Fanatec, as share...

- Thomas Harrison-Lord

- Updated:

- 3 min read

-

Funselektor Teases Another Potential New ProjectNot content with the upcoming 2D management title Golden Lap, the creators of Art of Rally look...

- Thomas Harrison-Lord

- Updated:

- 2 min read

-

F1 24’s Updated Driver Career Mode DetailedThe new aim of F1 24's driver career is to increase your recognition levels, and ultimately...

- Thomas Harrison-Lord

- Updated:

- 3 min read

-

Assetto Corsa Competizione’s Nordschleife Hits Consoles 2nd MayThe Nürburgring 24hr Pack DLC for Assetto Corsa Competizione arrives this time next week for...

- Thomas Harrison-Lord

- Updated:

- 2 min read

-

BeamNG Hotfix Adds Vehicle Detail Viewer And A Slew Of FixesBeamNG.drive's 0.32 update has been a huge hit with fans, the obligatory patch to partner the...

- Connor Minniss

- Updated:

- 3 min read