You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mobile Driving/Flying Cockpit with Motion and Tactile ( Build )

RCHeliguy

Premium

I've ordered the steel.

I'm considering using the following to finish the steel.

Acetone to clean the steel

Rustoleum Primer gray

https://www.amazon.com/gp/product/B00106IZLO

Rust-Oleum Hammered Silver

https://www.amazon.com/Rust-Oleum-24.../dp/B0016HLAJG

I'm considering using the following to finish the steel.

Acetone to clean the steel

Rustoleum Primer gray

https://www.amazon.com/gp/product/B00106IZLO

Rust-Oleum Hammered Silver

https://www.amazon.com/Rust-Oleum-24.../dp/B0016HLAJG

RCHeliguy

Premium

Steel arrives Tuesday, Rustoleum arrives on Wednesday.

I'll do some recon at the Maker center Tuesday night. Mostly I'm curious how I'm going to cut the 6" wide steel plate. I think I can use the bandsaw cutter with coolant, but I think I can use the upright metal bandsaw for 1018 as well.

I'll probably run the 2"x2" angle through the chop saw.

I may do the cutting, drilling, beveling on Wednesday and if it looks good start welding after that.

I'll likely clean it up at home and spray the rustoleum then.

Should be interesting!

I'll do some recon at the Maker center Tuesday night. Mostly I'm curious how I'm going to cut the 6" wide steel plate. I think I can use the bandsaw cutter with coolant, but I think I can use the upright metal bandsaw for 1018 as well.

I'll probably run the 2"x2" angle through the chop saw.

I may do the cutting, drilling, beveling on Wednesday and if it looks good start welding after that.

I'll likely clean it up at home and spray the rustoleum then.

Should be interesting!

Best of luck with it! Looking forward to seeing the final results.

RCHeliguy

Premium

The steel didn't arrive until last night around 7pm, so I'm not as far along as I thought I might be by now.

I could have had them cut these parts closer to what I needed, but historically they have tended to rough cut the material. The aluminum I've received has been pretty rough. I was surprised to find that the cuts on this steel are actually pretty square and clean after a bit of deburring.

I've got the steel marked and punched. The maker center has some bits that I may use, but I'll bring my own just in case and I'm definitely using my bevel bit for the 3/8" TST bolt.

Dealing with steel scale is new to me, but I don't plan to clean the steel until it is completely cut and drilled. I want the rust protection for now. So after it is all cut and drilled, I'll just clean the areas I plan to weld and then I'll clean the whole thing before I prime it. I'll bring a large cardboard box with me to use as a spray booth.

I could have had them cut these parts closer to what I needed, but historically they have tended to rough cut the material. The aluminum I've received has been pretty rough. I was surprised to find that the cuts on this steel are actually pretty square and clean after a bit of deburring.

I've got the steel marked and punched. The maker center has some bits that I may use, but I'll bring my own just in case and I'm definitely using my bevel bit for the 3/8" TST bolt.

Dealing with steel scale is new to me, but I don't plan to clean the steel until it is completely cut and drilled. I want the rust protection for now. So after it is all cut and drilled, I'll just clean the areas I plan to weld and then I'll clean the whole thing before I prime it. I'll bring a large cardboard box with me to use as a spray booth.

Amazed that runout did not doom that bandsaw cut.

RCHeliguy

Premium

It cut pretty straight. What might be more amazing is that I had interference with the steel sheet and I had to reverse the piece and cut it from the other end to meet in the middle. Then I cleaned it up on the high speed belt sander. So yeah, it was better than I expected too.Amazed that runout did not doom that bandsaw cut.

Tomorrow I'm going to use their MASSIVE upright bandsaw to trim the hot rolled angle and then I'll be ready to start welding

RCHeliguy

Premium

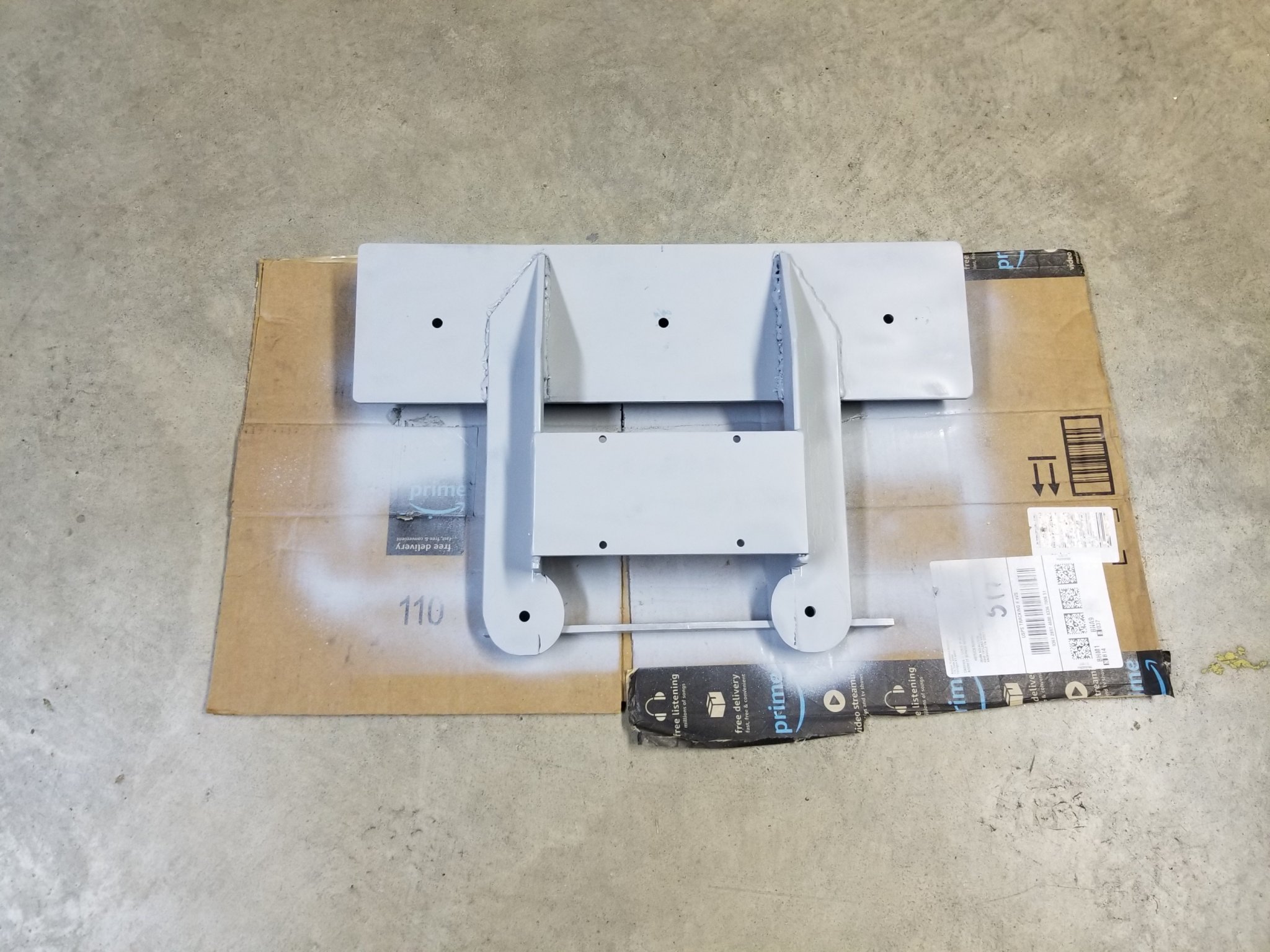

Waiting for the primer to dry enough to handle the complete part and take it home. It's very wet outside and after some effort to get the mill scale off, I wanted to protect the steel while it was freshly stripped.

I took more in process pictures with my DSLR. The welds were not as pretty as the last time I was out here, but they will hold fine.

It will look much better from the top

It will take 24 hours for the primer to completely dry and another 24 hours for the paint to dry. So I'm looking at being able to try this out on January 2nd.

I took more in process pictures with my DSLR. The welds were not as pretty as the last time I was out here, but they will hold fine.

It will look much better from the top

It will take 24 hours for the primer to completely dry and another 24 hours for the paint to dry. So I'm looking at being able to try this out on January 2nd.

Last edited:

RCHeliguy

Premium

Here are the details.

I started on the industrial 3 phase metal band saw.

Then used the belt sander to get the edges flush.

Preparing to flush weld small extensions, sanded small chamfers to leave room for a weld after sanding flat.

The flush welds are not fully ground flat yet, preparing to tack the frame together.

Notice the oops with the extra holes on the foot plate! I had a very bad measurement yesterday, so I drill correct holes today. That's one reason I took the hole pedal frame with me to verify things today. I welded the wrong holes shut later.

Test fit while only tacked together.

Spend some quality time removing the mill scale. The flush welds are looking more flush here.

Waiting for the primer to dry.

My welding still needs work, but it's not coming apart.

It should look a lot better after paint tomorrow.

I started on the industrial 3 phase metal band saw.

Then used the belt sander to get the edges flush.

Preparing to flush weld small extensions, sanded small chamfers to leave room for a weld after sanding flat.

The flush welds are not fully ground flat yet, preparing to tack the frame together.

Notice the oops with the extra holes on the foot plate! I had a very bad measurement yesterday, so I drill correct holes today. That's one reason I took the hole pedal frame with me to verify things today. I welded the wrong holes shut later.

Test fit while only tacked together.

Spend some quality time removing the mill scale. The flush welds are looking more flush here.

Waiting for the primer to dry.

My welding still needs work, but it's not coming apart.

It should look a lot better after paint tomorrow.

RCHeliguy

Premium

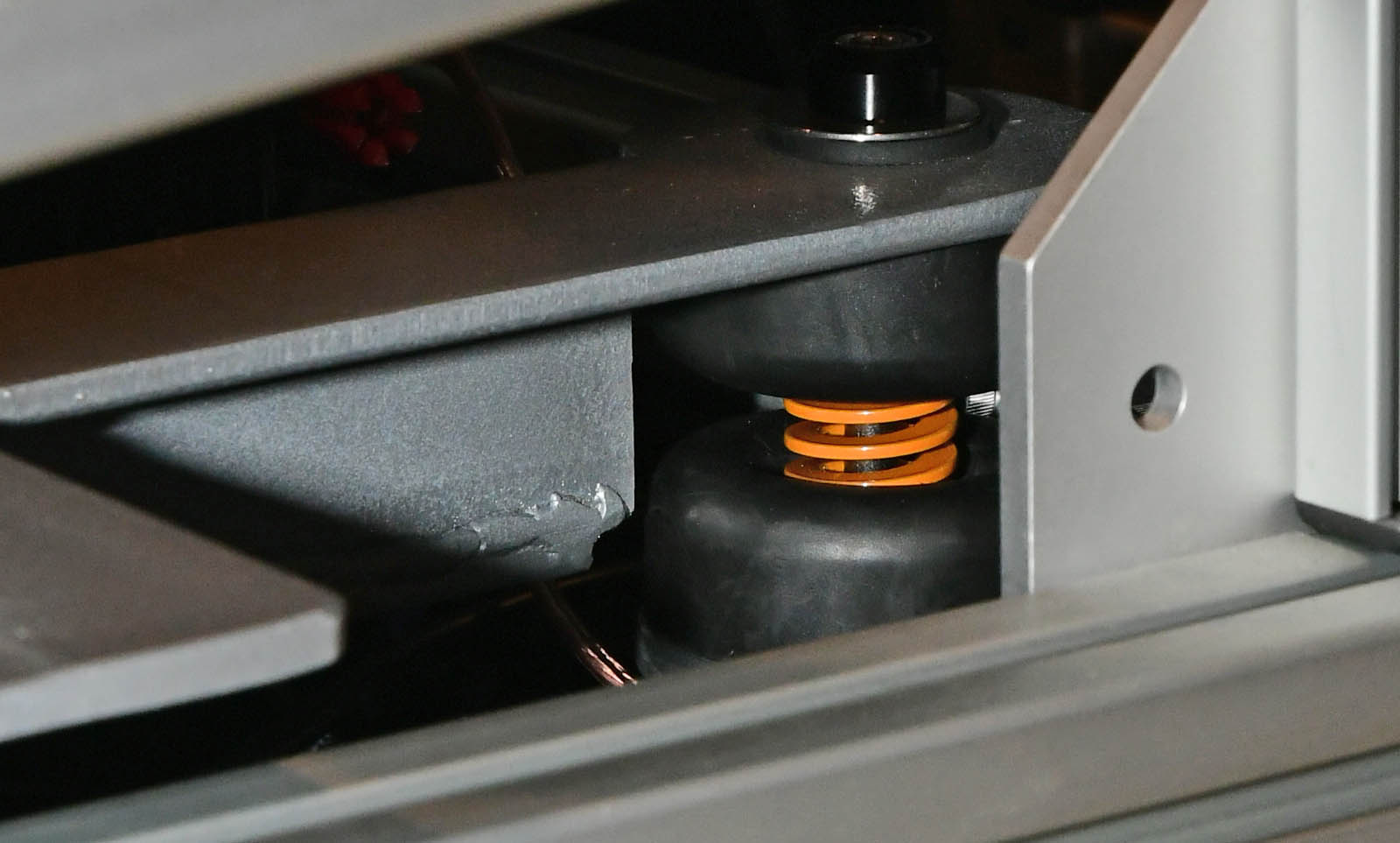

The verdict is that this was worth it. I am now getting the lower kicks from the BK-CT like I was expecting.

The seat already feels great and I have no issues with it whatsoever, and the footplate wasn't "bad" before, but it wasn't at the same level as the seat. I had experimented with weaker yellow springs on my earlier aluminum footplate and it was an improvement, but I was still losing the KICK I was expecting from the BK which I think was being lost through the flex in the aluminum structure and because it is off axis.

I tried the new steel plate first with the original red springs that are working wonderfully on the seat and that I suspect would be great if I had my entire pedal deck completely isolated. However they felt muted. The yellow springs by comparison feel MUCH better. By that I mean that I am now running identical power levels to the front BK-CT and rear BK-CT and they feel matched well and appropriate. The TST-329 being directly between my heels on the plate is doing a great job and is well matched with the TST-429 under my seat which is twice as efficient as the 329 is. I am able to also use the same power for both and they feel right.

I'm not sure how much more balanced I could make this, but it is well past the point of my feeling any need to tinker with either the transducers I'm using or their mounts. I feel like my hardware tactile solution is dialed in where I want it now. There is ample excess power that I'm not using and all the effects are coming through loud and clear. I think because it is running so efficiently, I'm able to run my transducers at low enough levels that I'm not sensing any of the effects being drowned out or lost in the crowd so to speak.

The exciters on the back of my seat continue to complete the immersion with the other 4 transducers. I also can't see needing any additional exciters. They come through in flying colors.

Color me very happy

The seat already feels great and I have no issues with it whatsoever, and the footplate wasn't "bad" before, but it wasn't at the same level as the seat. I had experimented with weaker yellow springs on my earlier aluminum footplate and it was an improvement, but I was still losing the KICK I was expecting from the BK which I think was being lost through the flex in the aluminum structure and because it is off axis.

I tried the new steel plate first with the original red springs that are working wonderfully on the seat and that I suspect would be great if I had my entire pedal deck completely isolated. However they felt muted. The yellow springs by comparison feel MUCH better. By that I mean that I am now running identical power levels to the front BK-CT and rear BK-CT and they feel matched well and appropriate. The TST-329 being directly between my heels on the plate is doing a great job and is well matched with the TST-429 under my seat which is twice as efficient as the 329 is. I am able to also use the same power for both and they feel right.

I'm not sure how much more balanced I could make this, but it is well past the point of my feeling any need to tinker with either the transducers I'm using or their mounts. I feel like my hardware tactile solution is dialed in where I want it now. There is ample excess power that I'm not using and all the effects are coming through loud and clear. I think because it is running so efficiently, I'm able to run my transducers at low enough levels that I'm not sensing any of the effects being drowned out or lost in the crowd so to speak.

The exciters on the back of my seat continue to complete the immersion with the other 4 transducers. I also can't see needing any additional exciters. They come through in flying colors.

Color me very happy

Last edited:

Weaker yellow springs + higher mass = lower resonant frequency, perhaps closer to excitation.

RCHeliguy

Premium

Weaker yellow springs + higher mass = lower resonant frequency, perhaps closer to excitation.

Maybe so.

All I know is that it is working like a charm and I had a lot of fun driving today.

I'm going to try to get some good racing going in the early morning for a while.

As @blekenbleu said, there is less mass as part of the resonant circuit (excuse the electrical terms, but the physics are analog as the inverse of the spring constant can be seen as being equivalent to a capacitor and the mass being equivalent to an inductor) the spring and mass form on the pedals, so the resonance frequency increases by a factor of ~5 compared to the seat, probably to a point where energy is transmitted much more efficiently than far above the natural frequency. By lowering the spring constant by ~2-3 and the increased mass of the steel assembly you are compensating for that effect.Maybe so.

All I know is that it is working like a charm and I had a lot of fun driving today.

I'm going to try to get some good racing going in the early morning for a while.

Btw i was also very happy with the heavy springs under the seat and not so happy with the same springs under the pedals.

Last edited:

RCHeliguy

Premium

Interesting. FYI, I am a BSEE, so I don't mind the technical discussion. Do you have a fully suspended pedal deck including your pedals, or is it just a foot plate like mine. Given my pedals are static, I don't worry about undo flex.

I'm not sure the yellow springs would handle braking pressure well.

I'm not sure the yellow springs would handle braking pressure well.

Last edited:

I have a pedal base plate that sits on top of 4 isolators holding an LFE and TST. On top of that i put secondary plates, either containing my race pedals or my rudder pedals with quick-locks "metal-on-metal".Interesting. Do you have a fully suspended pedal deck including your pedals, or is it just a foot plate like mine.

I'm not sure the yellow springs would handle braking pressure well.

Personally i was never so picky about the minimal flex reasonable isolation induces, but i am also not running super-heavy load cells, i am on Fanatec V3s. I also think the "spring-flex" feels better, as it is more of a spring compression then actual horizontal flex like with rubber solutions.

I understand you have upside-down pedals, that might increase the issue due to the lever.

Last edited:

Maybe the language barrierYou missed my point that my pedals are rigidity attached to my chassis and the only sprung section is the plate my heals rest on. So having lighter springs has no impact on my braking.

Last edited:

Latest News

-

IndyCar Secures Game Assets Following Settlement With Motorsport GamesAfter intending to terminate the license in late 2023, IndyCar has reached a settlement with...

- Yannik Haustein

- Updated:

- 2 min read

-

2024 Formula One Monaco Grand PrixOne of the most hotly anticipated Formula One races of the season once again takes place on the...

- Connor Minniss

- Updated:

- 2 min read

-

WATCH: F1 24 Updated Tracks ComparisonF1 24 promises updated versions of no less than four tracks, bringing them up to their current...

- Yannik Haustein

- Updated:

- 1 min read

-

1995 Indianapolis 500: Remembering The Final Pre-Split SpectacleThe 2024 edition of the Indianapolis 500 is just around the corner - a race steeped in history...

- Yannik Haustein

- Updated:

- 9 min read

-

OT Mods: Aussie Supercars Liveries Hit Assetto Corsa CompetizioneAcross sim racing, there are very few Australian Supercars available in first party content, and...

- Angus Martin

- Updated:

- 3 min read

-

F1 24 Preview: First Impressions, Handling & New Game ModesThe wait for Formula One fans is almost over, as F1 24 is going to release next week. We got to...

- Yannik Haustein

- Updated:

- 6 min read

-

IMMERSION Modding Group Adds 9 Scenarios To 1986 F1 Season PackAfter exploring some of its possibilities, the IMMERSION Modding Group XML Selector now gets...

- Yannik Haustein

- Updated:

- 2 min read