You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mobile Driving/Flying Cockpit with Motion and Tactile ( Build )

RCHeliguy

Premium

I apologise, but I find them a bit cheesy. Well made though.

Trust me, I completely understand and I'm still not sold on them. That said, if for some reason I fall in love with them, please forgive me for liking something cheesy

Last edited:

RCHeliguy

Premium

Based on the feedback I've gotten on multiple boards I've jumped the shark with this one.

I'm seeing about 1:4 - 1:5 AGAINST putting tail pipes on a sim rig.

I've gotten "very tacky" but also "very cool". However the complements are in the minority by a margin.

I wanted to know and now I do

I'm seeing about 1:4 - 1:5 AGAINST putting tail pipes on a sim rig.

I've gotten "very tacky" but also "very cool". However the complements are in the minority by a margin.

I wanted to know and now I do

Personally, I don't like them. Though it does look a lot better than I thought it would!

But to be honest mate, it's your rig and if you like it then sod what anyone else thinks!

Either way, it's a cool design so if you don't use them as tail pipes then I'm sure you'll find another use for them. Maybe cut out the bottom and stick a couple of fans in them for extra cooling?

But to be honest mate, it's your rig and if you like it then sod what anyone else thinks!

Either way, it's a cool design so if you don't use them as tail pipes then I'm sure you'll find another use for them. Maybe cut out the bottom and stick a couple of fans in them for extra cooling?

Not that it matters, but I am 'on the fence'......

I think they are really neat and offer something more. I mean, how is it any different than RGB lighting, decals, or something else? It looks fun and for sure would get a lot of smiles from guests.

On the other hand, it has that sort of Logitech-lets-make-the-front-of-our-wheel-look-like-the-front-of-a-car..... sort of vibe. Which is fine, but a bit cheesy.

If the exhaust tips were real metal, maybe proper tips with some heat discolouring, that maybe would be quite neat.

But if you go that route, then you cannot stop, and a set of proper racing rims and tires will be needed to attach to the four corners (would also give decent vibration dampening to the floor, I think....)

I think they are really neat and offer something more. I mean, how is it any different than RGB lighting, decals, or something else? It looks fun and for sure would get a lot of smiles from guests.

On the other hand, it has that sort of Logitech-lets-make-the-front-of-our-wheel-look-like-the-front-of-a-car..... sort of vibe. Which is fine, but a bit cheesy.

If the exhaust tips were real metal, maybe proper tips with some heat discolouring, that maybe would be quite neat.

But if you go that route, then you cannot stop, and a set of proper racing rims and tires will be needed to attach to the four corners (would also give decent vibration dampening to the floor, I think....)

RCHeliguy

Premium

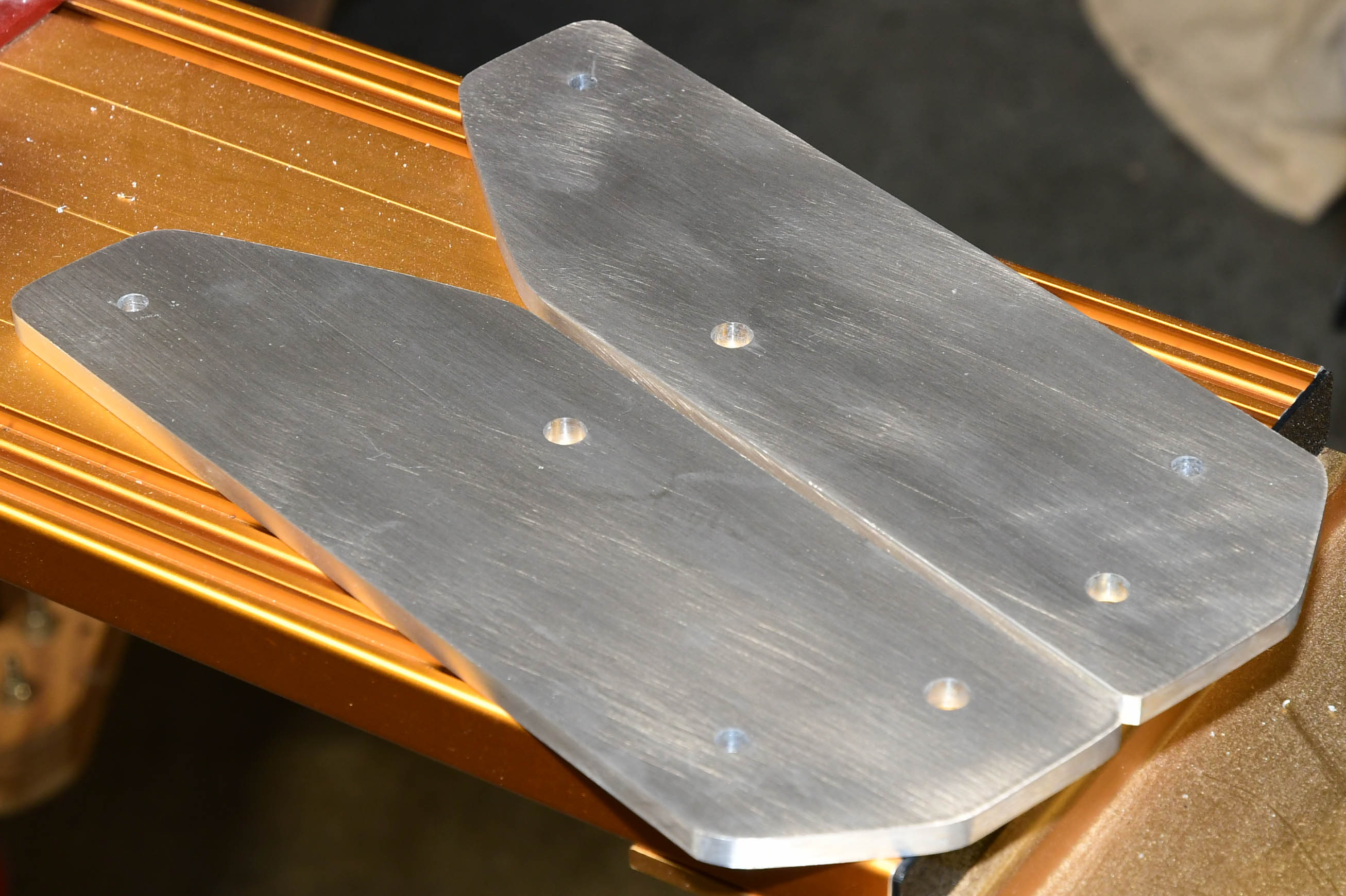

A little Aluminum work this morning.

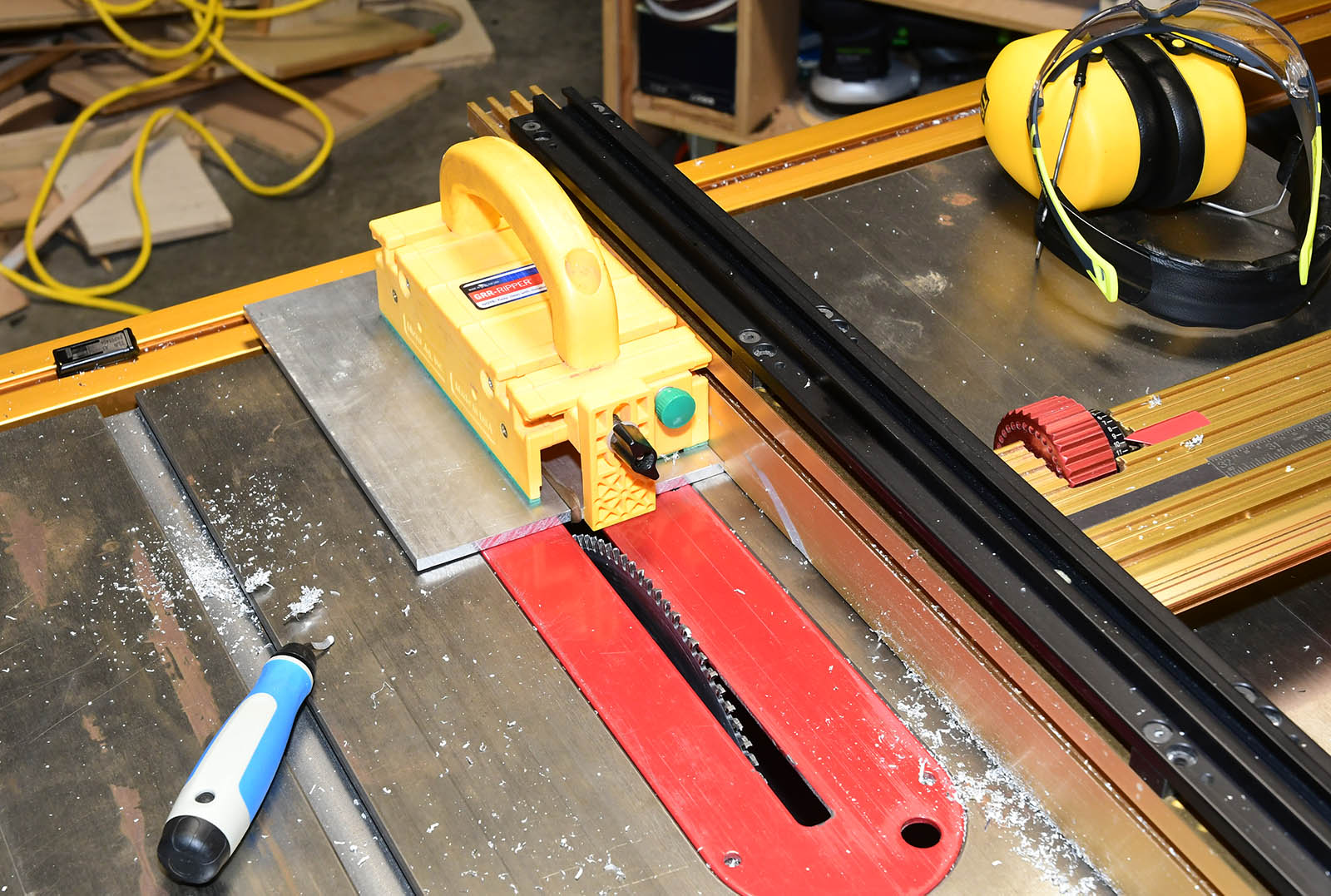

Cut 1/4" plate with my aluminum cutting blade.

I get a really nice edge with this blade.

The deburring tool is great to quickly take any sharp edges off.

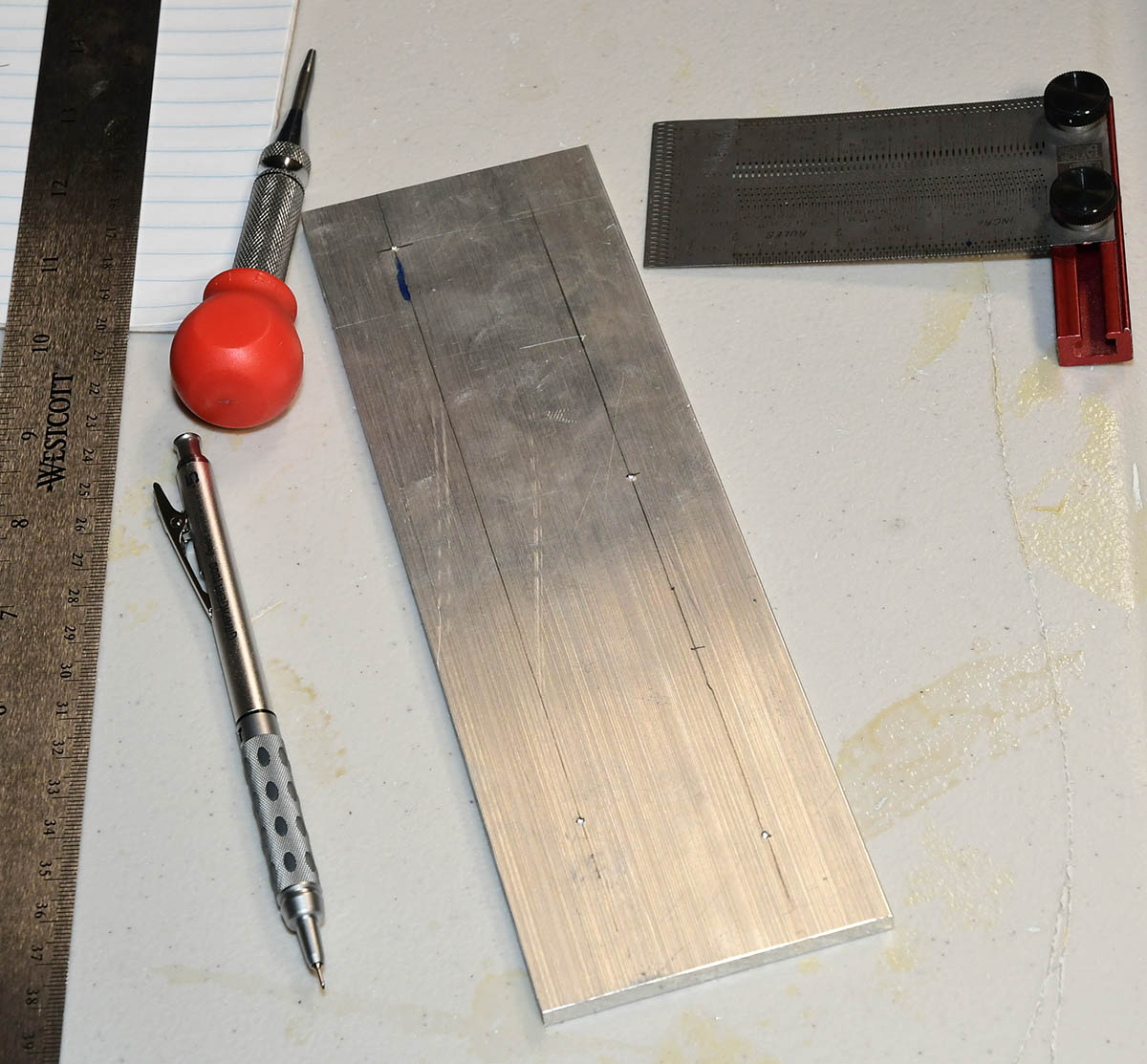

Then I measure where the holes go and use an auto punch to create center points. You press the auto punch and it pops making a divot.

In this case I'm cutting 6mm and 8mm holes with my drill press using WD40 as a cutting oil which is perfect for aluminum. There is double sided carpet tape between the two pieces to keep them aligned.

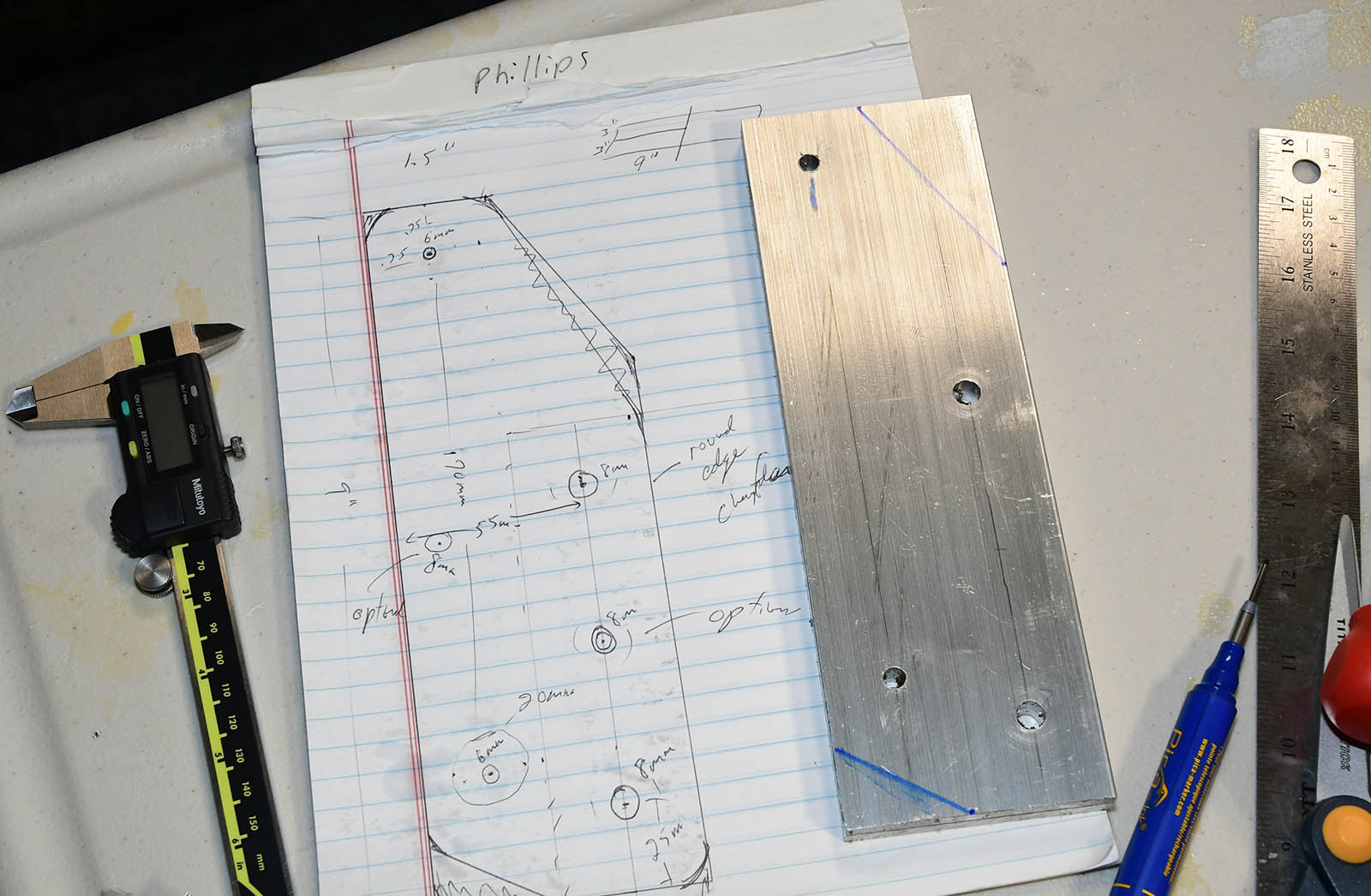

Mark the edges to trim off.

You can see two additional holes on the drawing. They were just in case I felt this needed any additional strengthening. Fortunately I won't need them.

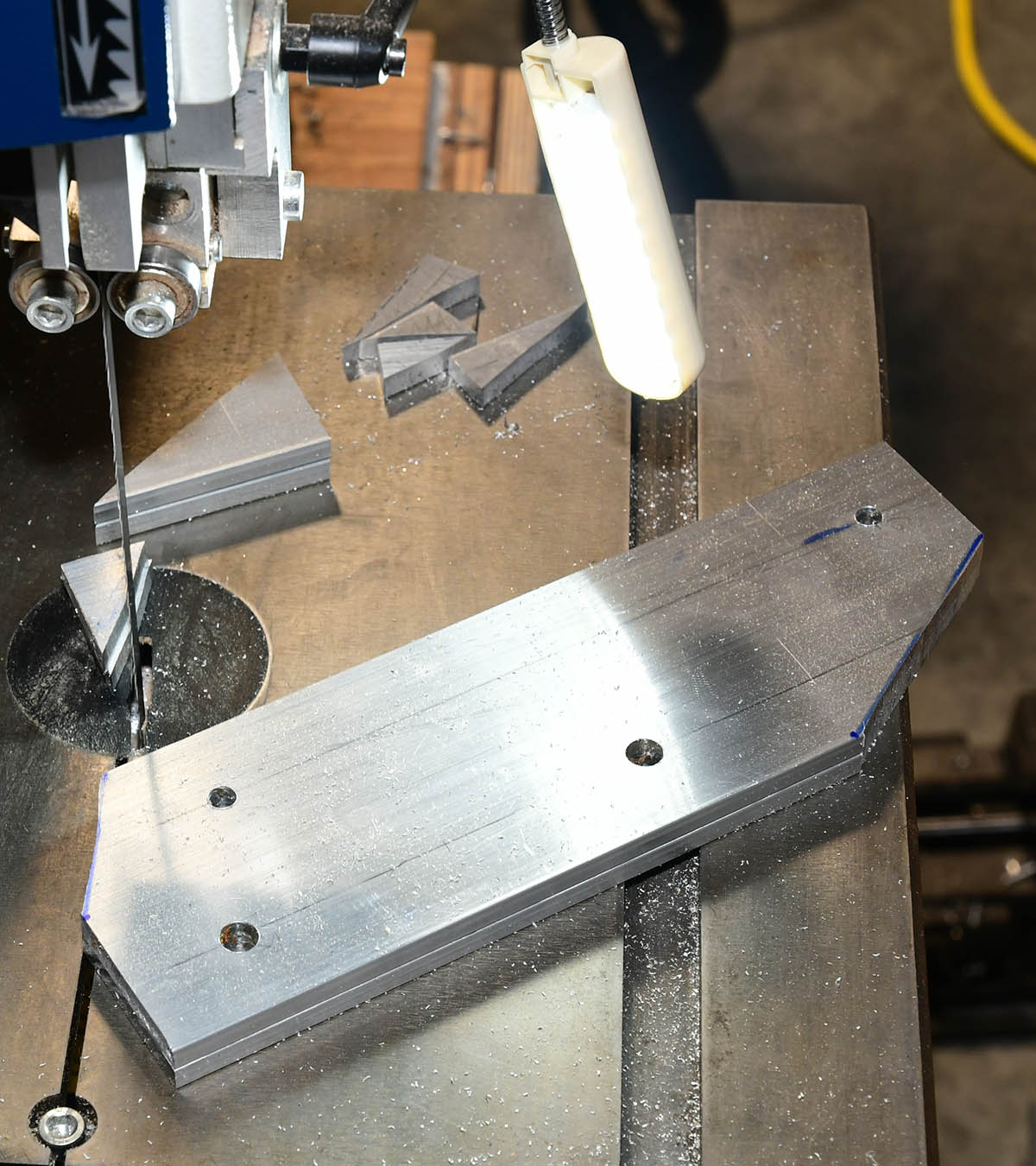

Take the corners off with my bandsaw.

Round and finish the edges using a 2" belt sander.

After a little hand sanding I have this.

Bolts holes line up perfectly.

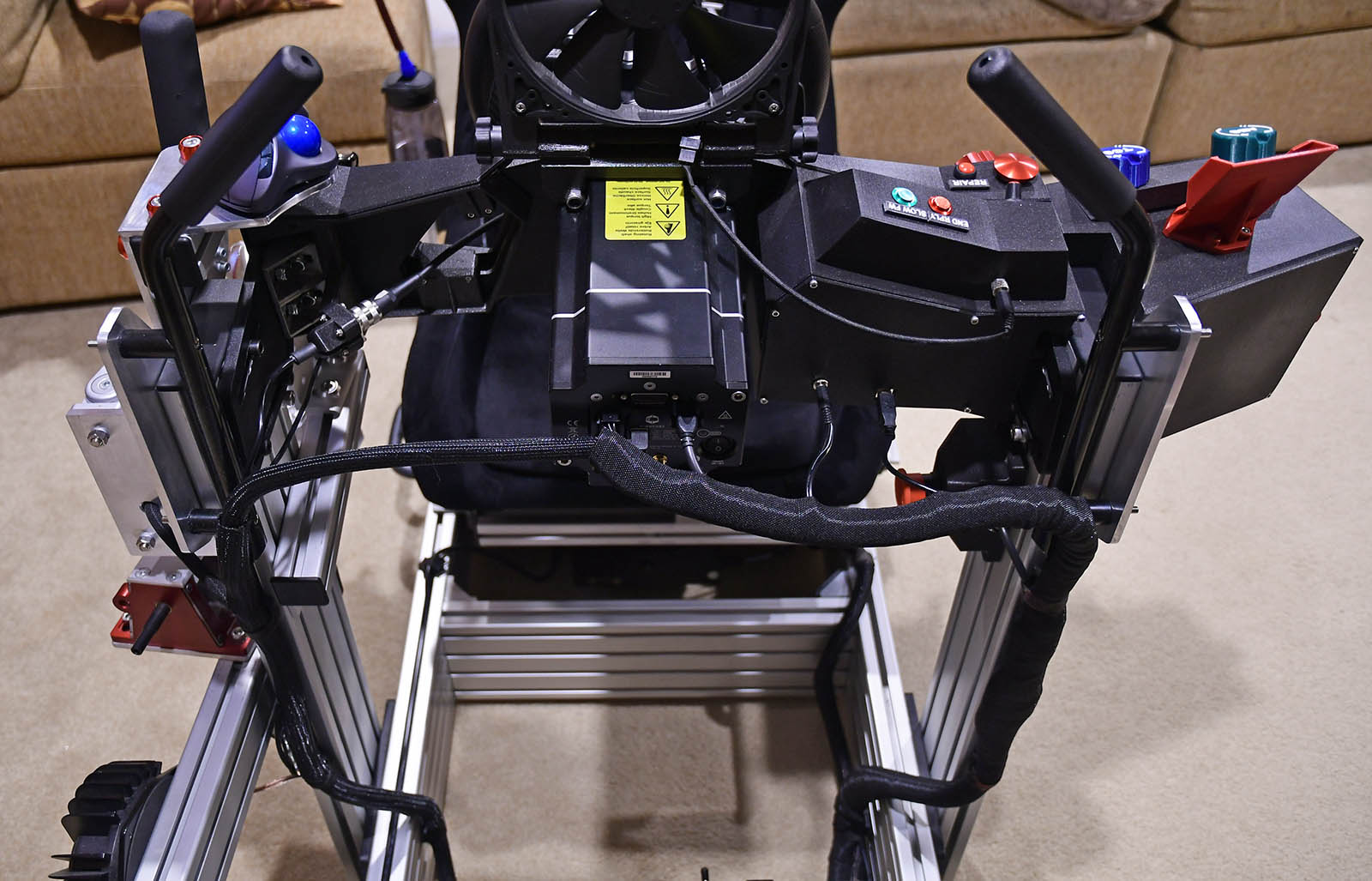

Here it is installed.

I've been trying to redesign my flight pedal mount, but finally I just went with the existing design and just dialed it in. However I'm using metal stops in the back and just press it against them and tighten from the front.

The cable cleanup and reorganization was in part to make the transition to flight mode cleaner and faster. My flight pedals were just interfering with a power supply, so I raised them a bit for clearance and moved the flight pedal tracks deeper into the back. The resulting pedal position feels great!

Earlier, I had mentioned that one of the reasons I wanted to redesign my button box is that my last button box interfered with where I wanted my flight throttle positioned.

My flight ergonomics now feel the way they should for the first time since I installed a bucket seat well over a year ago. Which is one reason I haven't been using it in flight mode much. I've been sort of fighting things with flight for a little while.

This should be a lot better.

Cut 1/4" plate with my aluminum cutting blade.

I get a really nice edge with this blade.

The deburring tool is great to quickly take any sharp edges off.

Then I measure where the holes go and use an auto punch to create center points. You press the auto punch and it pops making a divot.

In this case I'm cutting 6mm and 8mm holes with my drill press using WD40 as a cutting oil which is perfect for aluminum. There is double sided carpet tape between the two pieces to keep them aligned.

Mark the edges to trim off.

You can see two additional holes on the drawing. They were just in case I felt this needed any additional strengthening. Fortunately I won't need them.

Take the corners off with my bandsaw.

Round and finish the edges using a 2" belt sander.

After a little hand sanding I have this.

Bolts holes line up perfectly.

Here it is installed.

I've been trying to redesign my flight pedal mount, but finally I just went with the existing design and just dialed it in. However I'm using metal stops in the back and just press it against them and tighten from the front.

The cable cleanup and reorganization was in part to make the transition to flight mode cleaner and faster. My flight pedals were just interfering with a power supply, so I raised them a bit for clearance and moved the flight pedal tracks deeper into the back. The resulting pedal position feels great!

Earlier, I had mentioned that one of the reasons I wanted to redesign my button box is that my last button box interfered with where I wanted my flight throttle positioned.

My flight ergonomics now feel the way they should for the first time since I installed a bucket seat well over a year ago. Which is one reason I haven't been using it in flight mode much. I've been sort of fighting things with flight for a little while.

This should be a lot better.

Last edited:

My experience has been that Aerokroil works better than WD40,WD40 as a cutting oil which is perfect for aluminum

but Tap Magic 20004A Aluminum beats either cutting aluminum.

+1 for Tap Magic... got to really appreciate that stuff in the machine technology program I went through as well as the machine shop I used to instruct at. Aluminun doesn't need a cutting oil so much as it needs a cutting coolant. I often cut it dry on my table/chop saw though, and on my bandsaw (get a Lennox blade for your bandsaw btw) I sometimes use one of those wax stick things in the push-pop tube but I forgot the name atm

Also -1 on the pipes but I wasn't gonna try to spoil your fun but since you seem to be courting public opinion I appreciate form a lot but not when there is no function.

Also -1 on the pipes but I wasn't gonna try to spoil your fun but since you seem to be courting public opinion I appreciate form a lot but not when there is no function.

RCHeliguy

Premium

I got both grab handles mounted. Here is the back view. These things work very well.

@Wmacky went another route and has a hinge on his flight throttle so he can walk through. Or at least that was the plan. At the moment, I'm sticking with the removable bolt up connection for my flight throttle so I still have something to step over. I'd love to see a picture of your final solution if you don't mind sharing.

I thought I might print out 2 or 3 of these out of PETG. They are designed to use the 20mm wide velcro straps and countersunk M5 bolts I have in abundance.

@Wmacky went another route and has a hinge on his flight throttle so he can walk through. Or at least that was the plan. At the moment, I'm sticking with the removable bolt up connection for my flight throttle so I still have something to step over. I'd love to see a picture of your final solution if you don't mind sharing.

I thought I might print out 2 or 3 of these out of PETG. They are designed to use the 20mm wide velcro straps and countersunk M5 bolts I have in abundance.

Last edited:

LeeHetherington

Premium

I got both grab handles mounted. Here is the back view. These things work very well.

@Wmacky went another route and has a hinge on his flight throttle so he can walk through. Or at least that was the plan. At the moment, I'm sticking with the removable bolt up connection for my flight throttle so I still have something to step over. I'd love to see a picture of your final solution if you don't mind sharing.

Now that I'm just wrapping up the final setup for racing, and setup up all the racing sim software, I'm just now about to return to finishing up the flight mode part. The hinged throttle will work out just fine, and is the permanent solution. I find that stepping around the joystick is a pain. I'm going to try replacing the m8 mount bolts with the knurled plastic knobs, so the stick base can be pushed forward along the mount support beam, then slid back into position once seated.

RCHeliguy

Premium

I have these nice 20mm wide velcro straps that don't fit any of my cable clips for my rig and I had a bunch of M5 bevel head bolts and T-nuts laying around. I thought these would look much nicer than the thin velcro strips I was using.

So I made this. I may end up printing as many as 10 of these.

www.thingiverse.com

www.thingiverse.com

So I made this. I may end up printing as many as 10 of these.

40 series M4 and M5 Velcro Clip by RCHeliGuy

This is a Velcro strap clip for 40 series profile. Edit: 5/3/21 Added an M4 version. It uses an M5 bevel head bolt and is sized to fit the slot of 40 series profile. It has a single orientation. It fits the 20mm wide velcro straps I have and the M5 bevel headed bolts and M5 T-nuts I had laying...

Last edited:

RCHeliguy

Premium

Of course I say I can't think of one more thing to do to my rig and I find out ProSim is nearing production on their hydraulic shift lockout system.

<sigh> So yes there is one more thing that my rig needs to be complete. I just don't know when I'll be able to get it.

View attachment 441234

Hahahaha, you ever watch Columbo? "Just one more thing..."

I want to take this opportunity to thank you for sharing in this thread. Your journey has been an uplifting inspiration in many areas other than just simcraft. I started a family early (and got lazy) and never took my education past tradeschool. This has been first class entertainment for me.

Ps, I think the tailpipes are bloody awesome and can't wait to see how you incorporate the firelights! I've been planning brake lights all along.

RCHeliguy

Premium

Ps, I think the tailpipes are bloody awesome and can't wait to see how you incorporate the firelights! I've been planning brake lights all along.

Thanks for all the kind words! Sorry to say I was just joking when I mentioned the fire lights. There is a limit to my capacity for silly. The fake exhaust pipes are about as far as I go.

You could lose the mounting hardware and make one that simply locks by tuning 90 degs. I made some cable tidies in that fashion and it'd be perfectly solid for something like this.

USB plug holder with M5 hole by RCHeliGuy

I have a single USB plug connecting my Sim Rig's 10port USB 3.1 Hub to my computer and I wanted a secure way to hold it when I'm rolling my rig around. It uses an M5 Socket head bolt to a T-nutwww.thingiverse.com

Because the world needed another USB hanger and it only took 5 minutes to design the perfect USB hanger for me.

View attachment 438280

View attachment 438279

This worked, but it fell off at times. Now it won't.

View attachment 438281

Will post the file if you'd like to check it out.

First time I've caught up with this thread in a while. Lots of very nice stuff, but I won't share my thoughts on those exhausts

LeeHetherington

Premium

By the way, the cable tie twist thingies that work on SimLabs profile and on 8020.inc profile are different, even with both being 40 series. The depth of the slot shoulders are different.

Last edited:

RCHeliguy

Premium

By the way, the cable tie twist thingies that work on SimLabs profile and on 8020.inc profile are different, even with bit being 40 series. The depth of the slot shoulders are different.

I ran into that exact issue and ended up using a layer of masking tape to make some work. It's one reason I decided to use hardware. I actually prefer it.

Latest News

-

F1 24 Preview: First Impressions, Handling & New Game ModesThe wait for Formula One fans is almost over, as F1 24 is going to release next week. We got to...

- Yannik Haustein

- Updated:

- 6 min read

-

IMMERSION Modding Group Adds 9 Scenarios To 1986 F1 Season PackAfter exploring some of its possibilities, the IMMERSION Modding Group XML Selector now gets...

- Yannik Haustein

- Updated:

- 2 min read

-

Drag & Drift Races Return In New Need for Speed Unbound UpdateNeed For Speed Unbound has has added two classic modes from the series' history, as well as two...

- Luca Munro

- Updated:

- 2 min read

-

OverTake Goes Brickyard: Join Our OT IndyCar 500 (km) In rF2 For FreeIt is race week for the Biggest Spectacle in Racing, so our Racing Club is hosting its own...

- Yannik Haustein

- Updated:

- 2 min read

-

Max Verstappen's Busy Double-Victory WeekendMax Verstappen won the 2024 Formula One Emilia Romagna Grand Prix at Imola, but the Dutchman is...

- Yannik Haustein

- Updated:

- 3 min read

-

BMW M8 GTE Completes Trio Of New RaceRoom Cars (Updated With Patch Notes)After announcing the M2 CS Racing and the M4 GT4, RaceRoom unveiled the BMW M8 GTE to be the...

- Yannik Haustein

- Updated:

- 2 min read

-

Monster Jam Showdown: 'Just In Monster Jam' Trailer Shows New FeaturesThe team at Milestone have released the newest trailer for Monster Jam Showdown. From off-road...

- Connor Minniss

- Updated:

- 2 min read