Hey guys,

I'm helping out on Dallara GP3 formula car conversion to AC, and I do NOT want to use animated suspension on it, becasue I dislike the fact that if you adjust things like camber, they don't show up visually

Some time ago, I belive that someone did quite complex suspension like this using some axis nodes or so,

are there more people that got suspension working this way ?

yes, i have in mi car (Renault R24) :

I have done the suspensions with empty objects (arrows in this case) in blender, and when the suspensions move in the game or you change the camber or whatever, they move.

you have to use empty objects (in this case arrows if you use blender, although you can use another empty objects if you prefer, but have to be empty objects). first you have to include the wishbone of the suspension in one empty object (named : WISHBONE_LF) and later you have to create another empty object with the name "DIR_" in front of the name (example: DIR_WISHBONE_LF),

so it would be :

(from the help text of kunos, that you can see here : C:\Program Files (x86)\Steam\steamapps\common\assettocorsa\sdk\dev\car_pipeline_2.0rev\AC_Pipeline_PUB_Rev2.0.pdf) :

STEER ARMS and DIRECTION CONSTRAINTS We can animate many different parts and just import the animation to the editor and from that export to the game, but the STEER arm cannot be animated. Its position changes in the 3D space according to the HUB rotation.

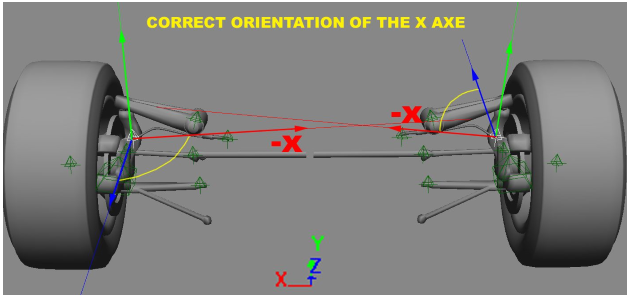

In order to constrain the movement of the steer arm to the HUB’s position and rotation, the convention name with a prefix “DIR_customName” must be used. This indicates the direction of the X negative axis of this mesh, and the null called “customName” will point the X axis to the correct direction.

Example: a null called “SteerArm_L” will point the negative X axis in direction of a null named “DIR_SteerArm_L” Pay attention to the rotation of the null which the animated mesh is linked to. In the image below the right-hand side Null point has a positive Z axis. The left Null point has a negative Z axis. This allows the -X axis to point to the center of the car or any other direction required by the mesh. Inside the TEMPLATE_Suspension_COMPLEX.fbx file, you can find a proper hierarchy example.

Note: You can create more constraints, if you have more objects to constraint to the HUB by simply giving them different names. Nevertheless, it is always good in terms of optimization to use the lowest possible number of constraints. You can animate your custom nulls in the following vectors: Rotation - Translation - Scale. Inside the TEMPLATE_Suspension_COMPLEX.fbx example file, you can see the animation of the suspension spring, on SCALE Y . Note: Never animate the mesh. Always animate the NULLs only! With this approach you can change and update your mesh every time you want without re-exporting the animations. Use the same technique to create animations for any NULL that has to be animated. For example, doors, gearbox levers, or any other parts.

the hierarchy is so (example of the left - front suspension) :

*(EO) = Empty Object

*(BO) = Blender object in cuestion (if you use blender)

(EO) DIR_WISHBONE_LF_1

(EO) DIR_WISHBONE_LF_2

(EO) DIR_WISHBONE_LF_3

(EO) DIR_WISHBONE_LF_4

(EO) SUSP_LF ---> (EO) WISHBONE_LF_1 ---> (BO) _WISHBONE_LF_1

-----------------------> (EO) WISHBONE_LF_2 ---> (BO) _WISHBONE_LF_2

-----------------------> (EO) WISHBONE_LF_3 ---> (BO) _WISHBONE_LF_3

------------------------> (EO) WISHBONE_LF_4 ---> (BO) _WISHBONE_LF_4

i hope this help you

ask more if you don't understand something or whatever