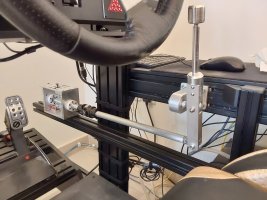

Hi All, currently replacing my old double H pattern shift I made (can't believe I made it 18 years ago!) with a more robust and hopefully better tactile feel version. I'm replacing the open gate style of the old one to a more race car type, the main reason being the number of times I got my finger caught in the open gate while using VR!

Give me a chance to get some pictures up here, and assuming it works well I am happy to post the CAD drawings up here for anyone to copy

Cheers

Les

Give me a chance to get some pictures up here, and assuming it works well I am happy to post the CAD drawings up here for anyone to copy

Cheers

Les

Last edited: