I recently started working on a DIY pedal set

first i would like to give a big thanks to Squidwert for his help in figuring out a lot of the stuff i wasn't sure of

here is my progress so far:

metal supplies i got

nuts, bolts, washers, springs, pots etc...

tubes cut to length to act as hinges

and the work done so far

the load cell finally arrived today (I have been waiting for it for quite a while and for some reason the tracking number shows it haven't left Hong-Kong yet)

just a couple of questions:

how much does the load cell flex when force is applied to it?

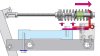

any one has any idea how the load cell is bolted to the actuator in these cst pedals?

is it just bolted to it or is there some kind of connection that allows some flex?

progress is quite slow because I didn't have the load cell's dimensions until now and just because of general lack of time.

hopefully i'll have new photos to upload soon

first i would like to give a big thanks to Squidwert for his help in figuring out a lot of the stuff i wasn't sure of

here is my progress so far:

metal supplies i got

nuts, bolts, washers, springs, pots etc...

tubes cut to length to act as hinges

and the work done so far

the load cell finally arrived today (I have been waiting for it for quite a while and for some reason the tracking number shows it haven't left Hong-Kong yet)

just a couple of questions:

how much does the load cell flex when force is applied to it?

any one has any idea how the load cell is bolted to the actuator in these cst pedals?

is it just bolted to it or is there some kind of connection that allows some flex?

progress is quite slow because I didn't have the load cell's dimensions until now and just because of general lack of time.

hopefully i'll have new photos to upload soon