For the servos, apparently there's 2 options available from Master Jiang if you ask. One has a cord attached to motor, the other has a connector on the motor. I chose option B, and will update with pics when I receive them. Allows me to change out to shielded power cable at some point by just changing the cable out.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Authorised Vendor Thanos AMC-AASD15A 6axis Servo Motion Controller

- Thread starter Tronicgr_6DOF

- Start date

How about some Open-hardware servo controller solution to match the FREE FlyPT mover motion software?

Not going to mention what can be used with. Take a wild guess...

View attachment 336275

View attachment 336276

here next to the fully loaded AMC-AASD15A (for size comparison)

Complete details on Github for gerber, parts list, firmware:

GitHub - tronicgr/AMC-open-hardware-servo-controller-4DOF: For use with 4DOF rigs with 100mm stroke actuators

For use with 4DOF rigs with 100mm stroke actuators - tronicgr/AMC-open-hardware-servo-controller-4DOFgithub.com

A few more videos...

Thanks for making this available. Would it be possible to create a non-smd version as I don't have the proper tools for smd soldering? Also it would be nice to have a schematic so one can build it without the need of the PCB.How about some Open-hardware servo controller solution to match the FREE FlyPT mover motion software?

Not going to mention what can be used with. Take a wild guess...

View attachment 336275

View attachment 336276

here next to the fully loaded AMC-AASD15A (for size comparison)

Complete details on Github for gerber, parts list, firmware:

GitHub - tronicgr/AMC-open-hardware-servo-controller-4DOF: For use with 4DOF rigs with 100mm stroke actuators

For use with 4DOF rigs with 100mm stroke actuators - tronicgr/AMC-open-hardware-servo-controller-4DOFgithub.com

Thanks for making this available. Would it be possible to create a non-smd version as I don't have the proper tools for smd soldering? Also it would be nice to have a schematic so one can build it without the need of the PCB.

Its not hard at all to solder small two contact SMD parts:

Soldering Basic SMD

Soldering Basic SMD: I am trying how to solder some basic SMD device, like 0805 package resistors, diode, capacitor, etc, there are some differences with the normal through hole soldering. First I got the SMD training PCB board here: http://www.electrodragon.com/…

At least, no one is asking you to solder from scratch the Arduino Mega 2560, right? Luckily, you can buy that already soldered from commercial outlets...!!

Last edited:

Thanks for making this available. Would it be possible to create a non-smd version as I don't have the proper tools for smd soldering? Also it would be nice to have a schematic so one can build it without the need of the PCB.

Actually I have a few AMC-open-hardware-servo-controller-4DOF PCBs with resistors, capacitors and LEDs soldered but as the moderators in this forum made abundant clear, they are not for sale... sorry. This forum is diehard DIY...

DIY g-seat with AASD-15A servo and pneumatics:

Last edited:

@thanos : I want to build something similar to the system showed in the video. It would be a 6DOF platform with 7 servo drivers. It is a 3DOF Dbox style with 4 servo drivers (for Heave, Roll and Pitch) over a platform with 3 servo drivers (for Sway, surge, Yaw, Rear traction loss and front traction loss). It has a very low center of gravity for a 6DOF plus RTL and FTL which is a good thing. Can this system be managed by AMC-AASD15A controller?

. More info: https://www.nextlevelracing.com/traction-plus-platform/

@thanos : I want to build something similar to the system showed in the video. It would be a 6DOF platform with 7 servo drivers. It is a 3DOF Dbox style with 4 servo drivers (for Heave, Roll and Pitch) over a platform with 3 servo drivers (for Sway, surge, Yaw, Rear traction loss and front traction loss). It has a very low center of gravity for a 6DOF plus RTL and FTL which is a good thing. Can this system be managed by AMC-AASD15A controller?. More info: https://www.nextlevelracing.com/traction-plus-platform/

Yes, it can be controlled by the AMC-AASD15A.

You can do it with 4DOF + RTL + FTL plus an extra output for belt (7th servo).

or 4DOF + RTL + FTL + Surge (7 servos total)

The mixing of axis can be done in Simtools axis assignments to mix the RTL and FTL into sway movement as well.

Thanks

Thanos

I gave a try on closed loop stepper motor I got on black Friday deal (delivered next day)... I used a 48v Power supply I had around.

A few observations.

-The price of the motor/driver (same power rating as 90ST motor) + power supply, is probably more than a ready to use AASD-15A motor/drive set...

-The closed loop system works good, making sure the motor goes to the target position, but there are NO parameters that you can do to set how it will go there. For example there is no acceleration/deceleration option or speed feedback control or tranjectory managment. If you feed it fast continuous pulses it will move to target instantly, if you feed it intermittent pulses it will be making small jumps to the target position...

Anyway judge for your self...

I ordered a 50:1 gearbox too to see if that will make a difference in motion and I'll try to interface to a linear actuator too sometime... It will be tricky on a linear actuator as it doesn't support home calibration using Torque, it will need limit switch...

A few observations.

-The price of the motor/driver (same power rating as 90ST motor) + power supply, is probably more than a ready to use AASD-15A motor/drive set...

-The closed loop system works good, making sure the motor goes to the target position, but there are NO parameters that you can do to set how it will go there. For example there is no acceleration/deceleration option or speed feedback control or tranjectory managment. If you feed it fast continuous pulses it will move to target instantly, if you feed it intermittent pulses it will be making small jumps to the target position...

Anyway judge for your self...

I ordered a 50:1 gearbox too to see if that will make a difference in motion and I'll try to interface to a linear actuator too sometime... It will be tricky on a linear actuator as it doesn't support home calibration using Torque, it will need limit switch...

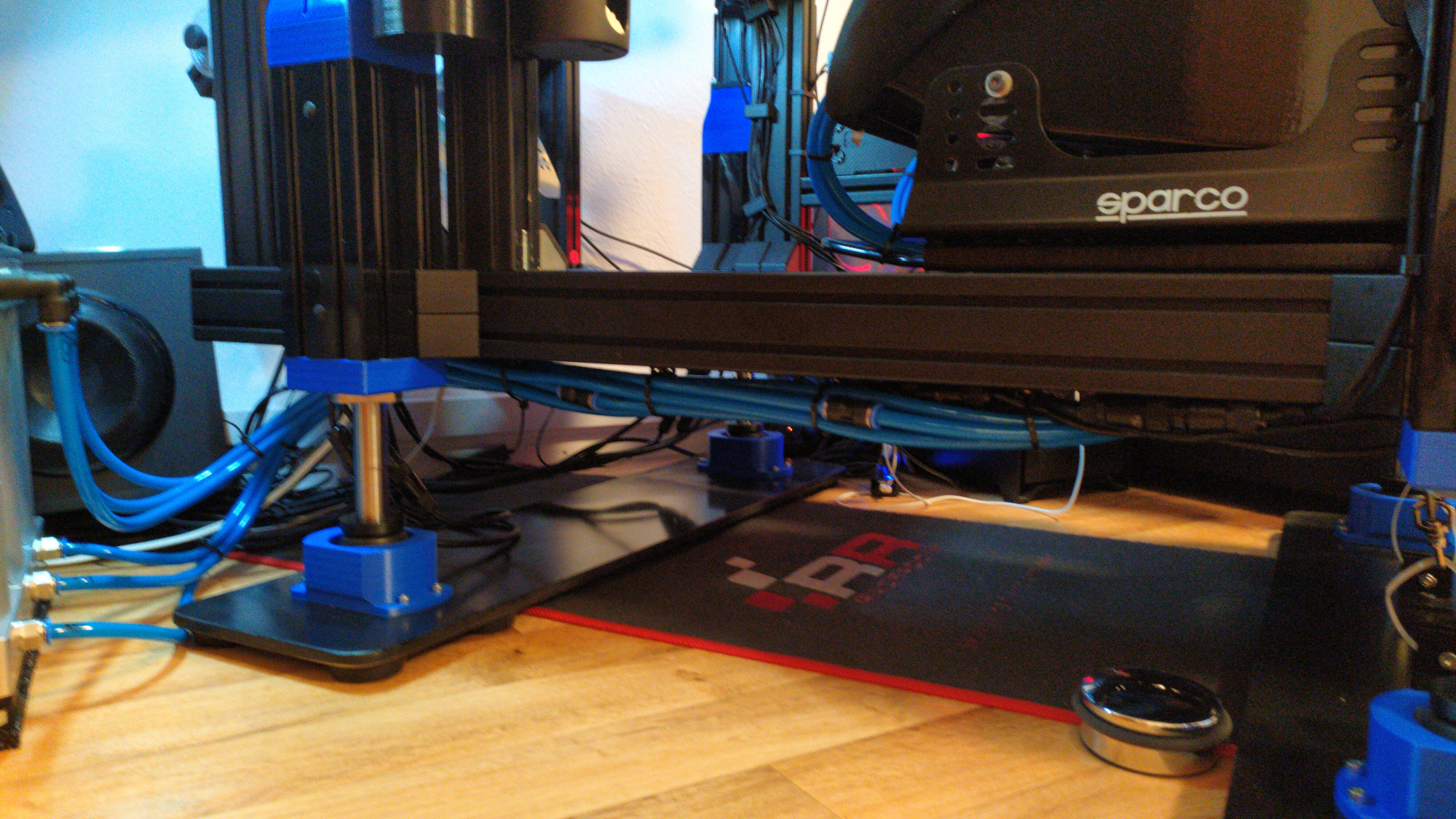

Hey, a few pics of the Version B of the motor from Master Jiang if anyone would like the option of the connector on the servo instead of the cable-style:

www.aliexpress.com

www.aliexpress.com

163.6€ 52% OFF|90ST M02430 220V 750W Ac Servo Motor 3000Rpm 2.4 N.M. 0.75KW Servomotor Eenfase Ac Drive Permanente Magneet Matched Driver|ac servo motor|ac servo motor 750wservo motor ac - AliExpress

Smarter Shopping, Better Living! Aliexpress.com

Hey, a few pics of the Version B of the motor from Master Jiang if anyone would like the option of the connector on the servo instead of the cable-style:

163.6€ 52% OFF|90ST M02430 220V 750W Ac Servo Motor 3000Rpm 2.4 N.M. 0.75KW Servomotor Eenfase Ac Drive Permanente Magneet Matched Driver|ac servo motor|ac servo motor 750wservo motor ac - AliExpress

Smarter Shopping, Better Living! Aliexpress.comwww.aliexpress.com

View attachment 337544

View attachment 337545

Is that the only option, vertically mount? It would be nice if there was a 90 degree solution so the cables do not poke out too much...

The EMI noise is very tricky to solve and in the case of the SFX100 it just conduit via the unfiltered arduino circuit... It essentially uses the USB connection to act like antenna. Sorry its not my design and I wish I could help more with that. I solved these issues on my controller by implementing filtered circuit design.

Thanks

Thanos

Hi Thanos, could you maybe explain in more detail how your design differs from the sfx100 arduino leonardo design and why it affects EMI issues? What do you mean by "filtered circuit design"? Judging from the schematics in the AASD servo driver manual the DB25 control interface is isolated by optocouplers, so there's no ground connection between the controller and the driver anyway regardless of the controller being used. And the EMI is generated at the driver and the motors, not the controller, right?

This is not meant to challenge your statements, I'd just like to understand the technical issues involved

Thanks

Hi Thanos, could you maybe explain in more detail how your design differs from the sfx100 arduino leonardo design and why it affects EMI issues? What do you mean by "filtered circuit design"? Judging from the schematics in the AASD servo driver manual the DB25 control interface is isolated by optocouplers, so there's no ground connection between the controller and the driver anyway regardless of the controller being used. And the EMI is generated at the driver and the motors, not the controller, right?

This is not meant to challenge your statements, I'd just like to understand the technical issues involved

Thanks

The DB25 connector on the AASD-15A servos is connected to the servo power ground and it can be carried to the microcontroller via the DB25 cable shield, and then in turn to the USB connector ground... This can give a nasty ground loop sometimes, affecting joysticks with ghosting or VR displays with gray-outs etc...

Apart from that, I use filtering for the output signals (OUT1, OUT2) from the servo drive that are simple sinking transistor directly interfaced to the servo drive control circuit, not via optocouplers, and carry lots of the EMI noise of the servo drive back to the Microcontroller. If these are not filtered the micro can go heywire...

Thanks

Thanos

See another update on this amazing DIY 6DOF. Its highly recommended using Traction loss instead of Yaw on such finite motion systems:

So the control pins are galvanically isolated, but the connector shield is connected to ground? Then it's actually quite easy to avoid ground loops: just don't the connect the shield of the DB25 connector on controller side to anything! Or alternatively use a cable that has the shield connected on only one side.The DB25 connector on the AASD-15A servos is connected to the servo power ground and it can be carried to the microcontroller via the DB25 cable shield, and then in turn to the USB connector ground... This can give a nasty ground loop sometimes, affecting joysticks with ghosting or VR displays with gray-outs etc...

Apart from that, I use filtering for the output signals (OUT1, OUT2) from the servo drive that are simple sinking transistor directly interfaced to the servo drive control circuit, not via optocouplers, and carry lots of the EMI noise of the servo drive back to the Microcontroller. If these are not filtered the micro can go heywire...

Thanks

Thanos

According to the schematic in the manual, also the output pins (sigOut1-4 in the manual) are optically isolated. Only the encoder outputs (A,B,Z) seem to have a ground connection. But no controller that I'm aware of uses those

Last edited:

I just made available new firmware for AMC-AASD15A. It incorporates soft transition to online mode, to avoid jumps when the vehicle is placed uphill or near the curb on the starting line...

This works best if its used in combination with the Force Office switch, to allow motion data after you started the game.

Its still beta as I'm still adding a few more things in there before release stable v2.08.

https://github.com/tronicgr/AMC-AAS...re/enc_6dof_AMC_AASD15A_v2_08_soft_start2.zip

See a quick video of testing it on my bench here:

This works best if its used in combination with the Force Office switch, to allow motion data after you started the game.

Its still beta as I'm still adding a few more things in there before release stable v2.08.

https://github.com/tronicgr/AMC-AAS...re/enc_6dof_AMC_AASD15A_v2_08_soft_start2.zip

See a quick video of testing it on my bench here:

Last edited:

Two thing Thanos:

1. The link doesn't work - I think it should be: https://github.com/tronicgr/AMC-AAS...are/enc_6dof_AMC_AASD15A_v2_08_soft_start.zip

2. I keep getting 'Connect Fail' when I try to program the Mega 2560. I get this using your latest and beta firmware versions. Any ideas?

Two thing Thanos:

1. The link doesn't work - I think it should be: https://github.com/tronicgr/AMC-AAS...are/enc_6dof_AMC_AASD15A_v2_08_soft_start.zip

2. I keep getting 'Connect Fail' when I try to program the Mega 2560. I get this using your latest and beta firmware versions. Any ideas?

View attachment 337771

I corrected the link. Thanks for noticing.

The AMC-AASD15A uses Atmega1280 microcontroller with custom encrypted bootloader.

Thanks

Thanos

Hi,

Added a small change in this beta firmware to automatically Park the actuators while the Force Offline switch is active. This way it won't try to go to middle position first before parking.

https://github.com/tronicgr/AMC-AAS...re/enc_6dof_AMC_AASD15A_v2_08_soft_start2.zip

Using a switch on the Force Offline input of the AMC-AASD15A servo controller, you can keep the actuators parked until you enter the race or runway, and release the force offline when you are positioned. The actuators will then presume the actual positions from the motion cues of the game, avoiding jolts or jumps if any difference between real and standby initial values that Simtools or FlyPT are sending to the AMC controller as soon serial connection is established.

Try it and let me know please!!

Thanks

Thanos

Added a small change in this beta firmware to automatically Park the actuators while the Force Offline switch is active. This way it won't try to go to middle position first before parking.

https://github.com/tronicgr/AMC-AAS...re/enc_6dof_AMC_AASD15A_v2_08_soft_start2.zip

Using a switch on the Force Offline input of the AMC-AASD15A servo controller, you can keep the actuators parked until you enter the race or runway, and release the force offline when you are positioned. The actuators will then presume the actual positions from the motion cues of the game, avoiding jolts or jumps if any difference between real and standby initial values that Simtools or FlyPT are sending to the AMC controller as soon serial connection is established.

Try it and let me know please!!

Thanks

Thanos

Last edited:

Latest News

-

Assetto Corsa Competizione’s Nordschleife Hits Consoles 2nd MayThe Nürburgring 24hr Pack DLC for Assetto Corsa Competizione arrives this time next week for...

- Thomas Harrison-Lord

- Updated:

- 2 min read

-

BeamNG Hotfix Adds Vehicle Detail Viewer And A Slew Of FixesBeamNG.drive's 0.32 update has been a huge hit with fans, the obligatory patch to partner the...

- Connor Minniss

- Updated:

- 3 min read

-

Gran Turismo 7’s Update 1.46 Includes Škoda’s Vision GTAn electric concept marks Škoda’s debut within Gran Turismo, and it will be joined by Honda’s...

- Thomas Harrison-Lord

- Updated:

- 4 min read

-

F1 Manager 2024’s New Mentality System, Pitbox Order DetailedAlongside being able to create a custom team, drivers can now be poached, races can be simulated...

- Thomas Harrison-Lord

- Updated:

- 2 min read

-

How The BTCC and Motorsport Games ReunitedIn a surprise move last week, official BTCC content will once again be present within rFactor 2...

- Thomas Harrison-Lord

- Updated:

- 5 min read

-

Sponsored MOZA Racing & Lamborghini Redefine Racing Boundaries with The Real Race Super Trofeo 2024MOZA Racing proudly announces its collaboration with Lamborghini for the launch of The Real Race...

- OverTake.gg

- Updated:

- 6 min read

-

Forza Horizon 5 Apex Allstars Update Adds Five New Race Cars, Plus Yet More DLCA new Apex Allstars Festival Playlist kicks off this Thursday in Forza Horizon 5, joined by a...

- Thomas Harrison-Lord

- Updated:

- 3 min read