4 channels vs 2 normally for small form factor amps like the nobsound. Built in power supply that actually matches the rated output of the device, with the smaller amps you can be supplied with under powered PSU's, or even no PSU at all and need to source your own, like when I bought mine. Perhaps not as matter or fact, but closer output to the specified rated power of the amp but that's always debatable how amps achieve their power output rating.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mobile Driving/Flying Cockpit with Motion and Tactile ( Build )

RCHeliguy

Premium

Thanks for that!

The bottom line is that I got what was recommended to me and it has all worked well.

I did not try out a bunch of amplifiers, or even research a bunch of amplifiers. I leaned on the research of others whose advice I trusted.

Tactile is an area where I've mostly just tried to set my system up to accommodate the efforts Mr.Latte.

I don't claim to be an expert on tactile. I'm pretty handy designing and building things and understand enough of his efforts to follow along. Past that I've just trusted his advise and run with it.

The bottom line is that I got what was recommended to me and it has all worked well.

I did not try out a bunch of amplifiers, or even research a bunch of amplifiers. I leaned on the research of others whose advice I trusted.

Tactile is an area where I've mostly just tried to set my system up to accommodate the efforts Mr.Latte.

I don't claim to be an expert on tactile. I'm pretty handy designing and building things and understand enough of his efforts to follow along. Past that I've just trusted his advise and run with it.

Last edited:

What would be some good ones with DSP that are good with exciters?There are some combination DSP amplifiers that are actually a better price point except that they have no physical volume knobs and need to be set in software.

I know the Behringer NX amps are recommended for the larger buttkickers and TST units, but I haven't seen a lower output model with builtin DSP.

I've been using the Douk M4 and t.racks DSP 4x4 mini to power and control my exiters. No problem with power capability and I've never had to turn the power knobs past 50%.What would be some good ones with DSP that are good with exciters?

Nowadays, t.racks have both a neater and cheaper all in one solution called the t.racks 4x4 mini amp which is what I'd go for if I were to do it again. They aren't always in stock but I see there is some B grade stock floating around at Thomann.

The Douk and t.racks products have a 50W/60W rating as opposed to the 75W of the EPQ304 but in my opinion that extra power isn't going to be required.

Last edited:

That actually looks to be a good option. Will just need to find a good step down voltage converter.I've been using the Douk M4 and t.racks DSP 4x4 mini to power and control my exiters. No problem with power capability and I've never had to turn the power knobs past 50%.

Nowadays, t.racks have both a neater and cheaper all in one solution called the t.racks 4x4 mini amp which is what I'd go for if I were to do it again. They aren't always in stock but I see there is some B grade stock floating around at Thomann.

The Douk and t.racks products have a 50W/60W rating as opposed to the 75W of the EPQ304 but in my opinion that extra power isn't going to be required.

RCHeliguy

Premium

Since we have come back to tactile again. I'm still in awe of what Mr. Latte is working on. He is relentless. I can barely keep up. Scratch that! I'm lucky to try out every 2nd or 3rd iteration of what he is working on and Peter is a machine as well adding to what is being developed and creating tools along the way. I'm glad the two of them have formed such a strong synergy. I wish I had time to help more, but I barely have time to use my rig lately.

Related to all that, what I've shown in my rig is more likely to scare people away from tactile both in complexity and cost. People are frequently asking for an inexpensive solution and my rig is the poster child for the opposite.

The good news is that I'm seeing progress being made both on the ever evolving high end with more elaborate effects that are continually being improved and a concept for an entry to tactile that is much easier to implement. Time will tell.

In other news I'm hoping to get some lathe training this weekend

Unfortunately I'm still pretty well covered up with work, so I'm not sure when I'll get a chance to create any videos or even use my rig

Related to all that, what I've shown in my rig is more likely to scare people away from tactile both in complexity and cost. People are frequently asking for an inexpensive solution and my rig is the poster child for the opposite.

The good news is that I'm seeing progress being made both on the ever evolving high end with more elaborate effects that are continually being improved and a concept for an entry to tactile that is much easier to implement. Time will tell.

In other news I'm hoping to get some lathe training this weekend

Unfortunately I'm still pretty well covered up with work, so I'm not sure when I'll get a chance to create any videos or even use my rig

Last edited:

The next step for my setup is some sort of integration of motion and or tactile. I really wish I could try out some of the product offerings before committing to buying as some are just so vastly different from each other. For example I don't know if I should go with a seat mover or full chassis motion. If I go full chassis I need to completely re-design my triple monitor solution. But at the same time the sigma DK2 is a full chassis motion with what appears to have pretty solid tactile also built in.Since we have come back to tactile again. I'm still in awe of what Mr. Latte is working on. He is relentless. I can barely keep up. Scratch that! I'm lucky to try out every 2nd or 3rd iteration of what he is working on and Peter is a machine as well adding to what is being developed and creating tools along the way. I'm glad the two of them have formed such a strong synergy. I wish I had time to help more, but I barely have time to use my rig lately.

Related to all that, what I've shown in my rig is more likely to scare people away from tactile both in complexity and cost. People are frequently asking for an inexpensive solution and my rig is the poster child for the opposite.

The good news is that I'm seeing progress being made both on the ever evolving high end with more elaborate effects that are continually being improved and a concept for an entry to tactile that is much easier to implement. Time will tell.

In other news I'm hoping to get some lathe training this weekend

Unfortunately I'm still pretty well covered up with work, so I'm not sure when I'll get a chance to create any videos or even use my rig

RCHeliguy

Premium

They each have their pros and cons.The next step for my setup is some sort of integration of motion and or tactile. I really wish I could try out some of the product offerings before committing to buying as some are just so vastly different from each other. For example I don't know if I should go with a seat mover or full chassis motion. If I go full chassis I need to completely re-design my triple monitor solution. But at the same time the sigma DK2 is a full chassis motion with what appears to have pretty solid tactile also built in.

I'm using a seat mover because of my space and mobility requirements. Otherwise I would have gone with a full chassis mover. I'm happy with it but realistically it's my only option at this point.

One limitation of my NLRv3 is that it can be overpowered and will shut down if you have heavy loadcell brake settings ( say 65-70kg+ )

You have to weigh the effort involved to accommodate full motion. It is a personal decision. I didn't have much of a choice, but it sounds like your choice is more related to the effort involved. Just make sure you don't do something to save time and then have regrets later.

While I do think a chassis motion system is mostly better than a seat mover, I'm not a believer in motion system tactile. It has too many downsides. First you really need to be in a basement on a solid foundation. Second you need to absolutely make sure every single bit of your rig is bolted snug so it won't rattle or have parts come loose. Full chassis tactile puts a lot more stress into everything than regular motion does. Past that there are other limitations that will keep it from comparing well to a well setup tactile setup, but there is additional cost and complexity to go that route.

I know a number of people who tried full motion tactile and didn't like it. They ended up with a separate tactile system. There are a few advocates for it and I've never tried it personally, so I'm basing part of my opinion on what I've heard from others. Like you I've not had any motion systems available to me to test out before buying.

Good luck however you go!

Last edited:

stigs2cousin

Premium

You could start (very) small with a custom shift knob for your H-Pattern

MFG Carsten

MFG Carsten

RCHeliguy

Premium

Very cool idea.You could start (very) small with a custom shift knob for your H-Pattern

MFG Carsten

Except it would be hard to improve on the H-Pattern shift knob I have right now. I really like this shift knob.

Contour - Gate 1

Enhanced grip and 500 grams of mass define the Contour's smooth and precise shifting experience. The grip ring is an intentional ergonomic undercut below the sphere that provides an ideal location for your fingers to sit, grip and shift.

But I think I could improve on the knob on my sequential shifter that I never use, so maybe variations on a theme ?

Last edited:

metalnwood

Premium

There is lots to be made on the lathe but sadly if I think about what is on my rig, there is not a lot for that which was made on the lathe.

Things pop up and the lathe is the perfect thing, for instance I needed a bolt, like the one that comes with the TST for mounting.. in fact it was for the TST but I wanted M10 on one aide and I think 5/16ths for the TST on the other.. The lathe is the go to for that. When I made my sfx actuators I didnt print the parts but made them on the lathe and mill.. The lathe was great for taxking the acetal, getting it down to the right diameter, boring one end of the nut and the other end for the piston. Then it was finished on the mill to fit inside the profile.

Many a round washer/spacer was made for things like seat mounting brackets. There are no sim related projects I can think of that I would do from beginning to end on a lathe but so many things happen in the workshop where the first thing you turn to is the lathe.

Over time you will turn to it for this and that and be pretty happy that you had an easy way to do whatever it was. It's uses will become more apparent as you do things on it.

Things pop up and the lathe is the perfect thing, for instance I needed a bolt, like the one that comes with the TST for mounting.. in fact it was for the TST but I wanted M10 on one aide and I think 5/16ths for the TST on the other.. The lathe is the go to for that. When I made my sfx actuators I didnt print the parts but made them on the lathe and mill.. The lathe was great for taxking the acetal, getting it down to the right diameter, boring one end of the nut and the other end for the piston. Then it was finished on the mill to fit inside the profile.

Many a round washer/spacer was made for things like seat mounting brackets. There are no sim related projects I can think of that I would do from beginning to end on a lathe but so many things happen in the workshop where the first thing you turn to is the lathe.

Over time you will turn to it for this and that and be pretty happy that you had an easy way to do whatever it was. It's uses will become more apparent as you do things on it.

RCHeliguy

Premium

Over time you will turn to it for this and that and be pretty happy that you had an easy way to do whatever it was. It's uses will become more apparent as you do things on it.

I've had that happen before. You don't think in terms of some solutions when you have no available means of doing something, but once you see the possibilities...

The 3D printer was a extreme example of this. I felt unleashed by that little work horse!

Last edited:

Other than fasteners, sim rig things with circular symmetry are steering hubs/extenders/adapterslearn the lathe

and (isolator) coil spring seats. For e.g. DIY direct drive harness tensioning, then perhaps spools.

RCHeliguy

Premium

Increased the BK-CT volume at the amp on the front by one notch and now it is feeling much better than it has in the past. I'm finally really feeling that BK goodness in front. I have my front 429 dialed back 1-2 notches compared to the back and my BK one notch forward. This is the first time that I've actually gotten what I wanted out of the BK in front. I'm still thinking the linear bearing idea was a good one.

Getting more comfortable with the new HE brake pedal and my lap times are basically even with where I was before. I had been a couple weeks without using my rig and the pedals all just felt right. I have no interest in adjusting anything right now.

Got the new iRacing F4 car and tried it out. I can see why Gamers Muscles and a few others are so fond of this car. It's very controllable and looks like a great entry point into open wheel racing.

I recalibrated my HE handbrake in DiView and got my controls setup again for the Ultimate+ pedals in RBR. RBR feels great!!! Now that my handbrake is configured properly, I can actually execute a nice sliding 180 degree turns in RBR. Dirt Rally 1.0 and 2.0 act more like an on/off switch when using the hand brake. RBR uses the hand brake in a much more linear way.

If I haven't made it abundantly clear the physics, FFB and tactile and in RBR feel much more realistic. I did have to dial back the tactile road vibrations and impacts a bit so the BK didn't knock after adding that extra notch at the amplifier. My NLRv3 settings for RBR are decent, but not as good as my configuration for DR, so I'll play with them a bit more. I may try to more closely mirror my DR settings.

I can see getting a lot more time in RBR going forward.

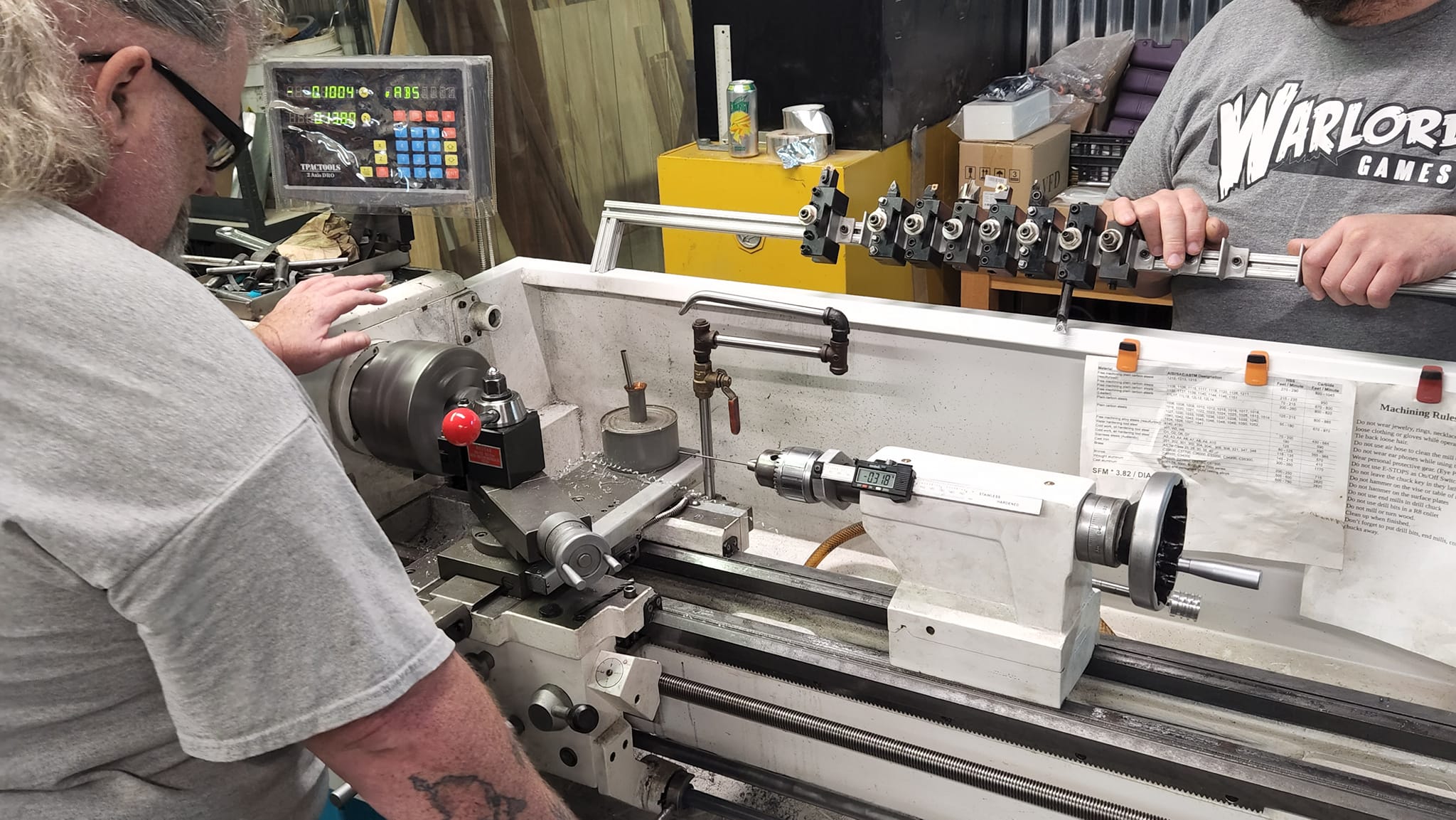

I made this impressive aluminum part yesterday, LOL.

However I did learn how to use the lathe well enough to do most things I would want to. However, we didn't cover making threads in this class which is an important feature of the lathe.

This is a 13x40 lathe with a pass through. They have quite a few accessories for it not showing in this picture including a quick release Collet attachment for use in place of the chuck.

Getting more comfortable with the new HE brake pedal and my lap times are basically even with where I was before. I had been a couple weeks without using my rig and the pedals all just felt right. I have no interest in adjusting anything right now.

Got the new iRacing F4 car and tried it out. I can see why Gamers Muscles and a few others are so fond of this car. It's very controllable and looks like a great entry point into open wheel racing.

I recalibrated my HE handbrake in DiView and got my controls setup again for the Ultimate+ pedals in RBR. RBR feels great!!! Now that my handbrake is configured properly, I can actually execute a nice sliding 180 degree turns in RBR. Dirt Rally 1.0 and 2.0 act more like an on/off switch when using the hand brake. RBR uses the hand brake in a much more linear way.

If I haven't made it abundantly clear the physics, FFB and tactile and in RBR feel much more realistic. I did have to dial back the tactile road vibrations and impacts a bit so the BK didn't knock after adding that extra notch at the amplifier. My NLRv3 settings for RBR are decent, but not as good as my configuration for DR, so I'll play with them a bit more. I may try to more closely mirror my DR settings.

I can see getting a lot more time in RBR going forward.

I made this impressive aluminum part yesterday, LOL.

However I did learn how to use the lathe well enough to do most things I would want to. However, we didn't cover making threads in this class which is an important feature of the lathe.

This is a 13x40 lathe with a pass through. They have quite a few accessories for it not showing in this picture including a quick release Collet attachment for use in place of the chuck.

Last edited:

RCHeliguy

Premium

Not quite yet. I haven't learned out to turn threads yet. It wasn't covered in the class.Now you can machine your own Raceseng threaded adapters for the Pro-Sim.

stigs2cousin

Premium

Of course you can cut threads with a lathe, but it´s a lot of work.Not quite yet. I haven't learned out to turn threads yet. It wasn't covered in the class.

Usually we just used the normal taps for threads.

Depending on the stock of your makers space this should be the easier and way faster option.

( In a very distant past in the last millenium I had mechanical training before my professional life went a completely different direction.)

MFG Carsten

RCHeliguy

Premium

There is another issue. A growing number of companies quickly and inexpensively macinine fusion 360 or solidworks models.

Having some familiarity with machining may end up helping me to understand what can be easily manufactured with minimal operations and tool changes.

Sending off a model to be manufactured is something that I haven't tried yet. Maybe it's time.

The last time I milled the mount for my sequential shift, I spent a chunk of time designing, then 3D printing two prototypes before I was happy with the design.

I spent an additional 8 hours to cut, mill, debur, and polish. Part of that was an experience I wanted to have, but it will become tedious work very quickly.

Having a 3D printer test print a part for verification and then sending a part off to be made may start to make more sense.

Having some familiarity with machining may end up helping me to understand what can be easily manufactured with minimal operations and tool changes.

Sending off a model to be manufactured is something that I haven't tried yet. Maybe it's time.

The last time I milled the mount for my sequential shift, I spent a chunk of time designing, then 3D printing two prototypes before I was happy with the design.

I spent an additional 8 hours to cut, mill, debur, and polish. Part of that was an experience I wanted to have, but it will become tedious work very quickly.

Having a 3D printer test print a part for verification and then sending a part off to be made may start to make more sense.

Last edited:

stigs2cousin

Premium

For me that doesn't sound like an issue but (lots of) future possibilitiesThere is another issue. A growing number of companies quickly and inexpensively macinine fusion 360 or solidworks models.

Having some familiarity with machining may end up helping me to understand what can be easily manufactured with minimal operations and tool changes.

Sending off a model to be manufactured is something that I haven't tried yet. Maybe it's time.

MFG Carsten

Latest News

-

Why The BTCC and Motorsport Games ReunitedIn a surprise move last week, official BTCC content will once again be present within rFactor 2...

- Thomas Harrison-Lord

- Updated:

- 5 min read

-

Sponsored MOZA Racing & Lamborghini Redefine Racing Boundaries with The Real Race Super Trofeo 2024MOZA Racing proudly announces its collaboration with Lamborghini for the launch of The Real Race...

- OverTake.gg

- Updated:

- 6 min read

-

Forza Horizon 5 Apex Allstars Update Adds Five New Race Cars, Plus Yet More DLCA new Apex Allstars Festival Playlist kicks off this Thursday in Forza Horizon 5, joined by a...

- Thomas Harrison-Lord

- Updated:

- 3 min read

-

F1 24's Updated Car Performance and Handling ExplainedWhile we haven’t tested it yet, on paper it sounds like significant changes have been made to...

- Thomas Harrison-Lord

- Updated:

- 3 min read

-

Tim Jarschel Wins 2024 DTM Esports Pro championshipCombining searing pace with consistency, Jarschel took home the title despite a charge from...

- Thomas Harrison-Lord

- Updated:

- 3 min read

-

Embracer Group Splits Into Three – Wreckfest, Milestone, Set For New HomesTwo racing game publishers are now forging their own paths as Embracer splinters into three...

- Thomas Harrison-Lord

- Updated:

- 3 min read

-

Recreating The Goodwood Members Meeting In Assetto CorsaThe Goodwood Members Meeting is one of the highlights of the British motorsport calendar. A...

- Connor Minniss

- Updated:

- 5 min read