You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HoiHman Race Rig & Rims showcase

- Thread starter HoiHman

- Start date

Looking great @Mcorp

i'm very much looking forward to receiving them.

@Elaphe, I drove with a 3d printed version of the paddle that @Mcorp has made for me and the shape is very very comfortable. The push/pull shifter is one of those upgrades that turned out much better then expected.

Since i sadly enough suffer from quite some arthrosis, comfort is from now the mainly drive to any adjustment i make to my rig. The push/pull shifter is one of those.

The HE-shifter is great, but after a while my shoulders/hands start to hurt. For better comfort i switched to a 350mm wheel in rally and now i still have that "manual shift feel" but without having to take my hands from the wheel.

The great thing about a fixed push/ pull shifter i that you can let the wheel spin out of the corners and grab it at exactly the right moment and start shifting again. This results in easier driving and faster stage times.

The push/pull shifter felt natural from the start and did not take any time to adjust to it. Some times people claim new hardware makes them faster, this time ( for me ) it's actually the case

I found a way to securely 'quick' mount the static shifter to my dash, without having to drill or use tools to mount or remove that push/pull shifter.

I completely agree that push-pull shifters are a great invention. I don't know why they are not used in more cars, apart from the WRC models . I think Lamborghini also implemented them in some of their supercars, so you can choose if you want to use the left paddle to downshift or instead push the right paddle, depending also of the current position of the driver's hands.

I also agree that it is a very comfortable way of shifting, as well as extremely effective, in the sense that it is very fast and precise, and you don't have to release your hands from the steering wheel. Also, the fixed position of the paddle makes it better for cars with high turning degrees and the extended length means that you can reach it from different positions of your hand on the rim (up to a certain point).

I used this kind of shifting mechanism for some time in my cockpit. However, despite of all of the said above, I find that I still prefer a good sequential lever. No matter if it's slower and less effective, the paddles didn't make me enjoy the physical act itself of using a lever, especially if you have a good mechanical shifter with a lot of feedback. It just feels more satisfying, more brutal and sturdy.

Last edited:

RCHeliguy

Premium

I found a way to securely 'quick' mount the static shifter to my dash, without having to drill or use tools to mount or remove that push/pull shifter.

I didn't realize that these were fixed! Suddenly this makes sense!

Yes @RCHeliguy, some have them attached to the wheel, but then it makes no sense imho.

Below is a picture of the complete assembly. The mounting plate hooks behind the dashboard at the bottom and is secured by (very) strong magnets at the top. On top of the plate i can mount the display with the same type of magnets. ( but most of the time i drive in VR without a display )

Since i'm not using any buttons on my rally wheel, i can use the same coiled cable from my rims for the push/pull shifter. The connector is raised a bit so it removes the slack that coiled cable usually has when it's connected to a rim.

Massive thanks to @Mcorp for the carbon pedals.

for the carbon pedals.

The 5mm carbon paddle is in a different category regarding overall stiffness compared to 5mm 3D printed version (@100% infill).

This results in a much better shifting experience at the top and bottom edges of the push/pull shifter.

For now the plate is covered with CF foil, but at some time in the future i will make an updated version and i will cover the mounting plate with the same high gloss carbon as my dashboard, making it almost invisible.

Below is a picture of the complete assembly. The mounting plate hooks behind the dashboard at the bottom and is secured by (very) strong magnets at the top. On top of the plate i can mount the display with the same type of magnets. ( but most of the time i drive in VR without a display )

Since i'm not using any buttons on my rally wheel, i can use the same coiled cable from my rims for the push/pull shifter. The connector is raised a bit so it removes the slack that coiled cable usually has when it's connected to a rim.

Massive thanks to @Mcorp

The 5mm carbon paddle is in a different category regarding overall stiffness compared to 5mm 3D printed version (@100% infill).

This results in a much better shifting experience at the top and bottom edges of the push/pull shifter.

For now the plate is covered with CF foil, but at some time in the future i will make an updated version and i will cover the mounting plate with the same high gloss carbon as my dashboard, making it almost invisible.

Last edited:

@RCHeliguy i use CTS288 rotaries to and would have preferred if they gave a little more feedback to

@HoiHman Fantastic rig you have, I find it very inspiring seeing the amazing craftsmanship and talents of individuals on this site. I myself am somewhat early on my sim journey but find myself very interested in printing and building my own projects. Thanks for sharing

P.S. Could you please let me know what you use for determining dimensions on your custom wheels? Is there a public repo where you can find this information on various GT cars and such?

P.S. Could you please let me know what you use for determining dimensions on your custom wheels? Is there a public repo where you can find this information on various GT cars and such?

Last edited:

@RedBull48 Thanks mate

There's no public repo where you can get the dimensions. I always start of with as many pictures of actual race car steering wheel as i can find.

For example if you know the wheel has a 70mm mounting pattern, you can use that to scale the picture to the actual size and make a drawing.

Get familiar with Fusion 360, since it's one of the best designing tools we have available for free.

In the beginning there will be a lot of trial and error. Something might look good in 3d, but it might feel strange, too large or too small in real life.

There's no public repo where you can get the dimensions. I always start of with as many pictures of actual race car steering wheel as i can find.

For example if you know the wheel has a 70mm mounting pattern, you can use that to scale the picture to the actual size and make a drawing.

Get familiar with Fusion 360, since it's one of the best designing tools we have available for free.

In the beginning there will be a lot of trial and error. Something might look good in 3d, but it might feel strange, too large or too small in real life.

Thanks for the input, I have recently started making my own models in fusion360 and it's great software. Still learning the ropes however. So far I have only made a few button box / project box designs along with a wheel mounted dash data display unit. @RCHeliguy I was not aware of that feature, that is awesome! Thanks for sharing.

I finally finished the BMW M4 GT4 steering wheel

The RaceLogic Display has now found a permanent spot on the left side of my dashboard.

I can still display all the racelogic data with it, but i now mainly use it to display the 4 most important values that i can tune live while driving:

-SFX intensity

-Tactile Intensity

-Belt Ofset (initial tension of 4 belts)

-Belt Strength

Belt strength is one of those values that needs a lot of live tuning. Usually i start with a comfortable high value, but often after 20-30 minutes of racing, the muscles in my body warn me to turn things down.

The live values can be displayed through a custom build simhub dashboard which is also shown on this video here:

The Note 3 has been fully converted to real race display which i can use to show all kinds of dashboard, including the SFX tuning, with SimHub

Further more there have a lot of changes to rig, which i wll update in another post.

The RaceLogic Display has now found a permanent spot on the left side of my dashboard.

I can still display all the racelogic data with it, but i now mainly use it to display the 4 most important values that i can tune live while driving:

-SFX intensity

-Tactile Intensity

-Belt Ofset (initial tension of 4 belts)

-Belt Strength

Belt strength is one of those values that needs a lot of live tuning. Usually i start with a comfortable high value, but often after 20-30 minutes of racing, the muscles in my body warn me to turn things down.

The live values can be displayed through a custom build simhub dashboard which is also shown on this video here:

The Note 3 has been fully converted to real race display which i can use to show all kinds of dashboard, including the SFX tuning, with SimHub

Further more there have a lot of changes to rig, which i wll update in another post.

Last edited:

This is an incredible piece of work. The world needs more rig-desk conversion designs so that people can have the best of both worlds. Back in post #27 you had a gif animation showing the conversion (presumably desk to rig), but the image has expired. Would it be possible to re-upload?

Last edited:

Thanks mateThis is an incredible piece of work. The world needs more rig-desk conversion designs so that people can have the best of both worlds. Back in post #27 you had a gif animation showing the conversion (presumably desk to rig), but the image has expired. Would it be possible to re-upload?

Sorry but that gif got lost somehow.

I finally got around to making a small video about my SFX DIY 4-Belt Tensioner

I've been using it in this configuration for more than a year now and the upgrade from an active tensioner from 2 to 4 belts is an impressive one.

Adding active tensioner on the lower belts

- Adds a lot of immersion

- Lowers the stress on the shoulders, while experiencing higher G-force simulation.

- Keeps the center buckle much better in place

- Because of the extra slack fastening the belts is so much easier

I haven't changed much on the 4-belt system in the last year, because there's not much to improve any more.

The only big change is the "on the fly adjust-ability" of the Intensity and Offset which is displayed through a custom SimHub dashboard.

After a 10-20 laps i always feel the need to turn things down, since the limit is not the system, but my body.

I've been using it in this configuration for more than a year now and the upgrade from an active tensioner from 2 to 4 belts is an impressive one.

Adding active tensioner on the lower belts

- Adds a lot of immersion

- Lowers the stress on the shoulders, while experiencing higher G-force simulation.

- Keeps the center buckle much better in place

- Because of the extra slack fastening the belts is so much easier

I haven't changed much on the 4-belt system in the last year, because there's not much to improve any more.

The only big change is the "on the fly adjust-ability" of the Intensity and Offset which is displayed through a custom SimHub dashboard.

After a 10-20 laps i always feel the need to turn things down, since the limit is not the system, but my body.

As i was looking over my own thread, i noticed that all my uploaded pictures got lost during the racedepartment forum update. Very very strange...

They were still there when editing the posts themselves, but not showing in the thread.

It took me more than an hour to change every single post, but they are all showing now again.

They were still there when editing the posts themselves, but not showing in the thread.

It took me more than an hour to change every single post, but they are all showing now again.

Last edited:

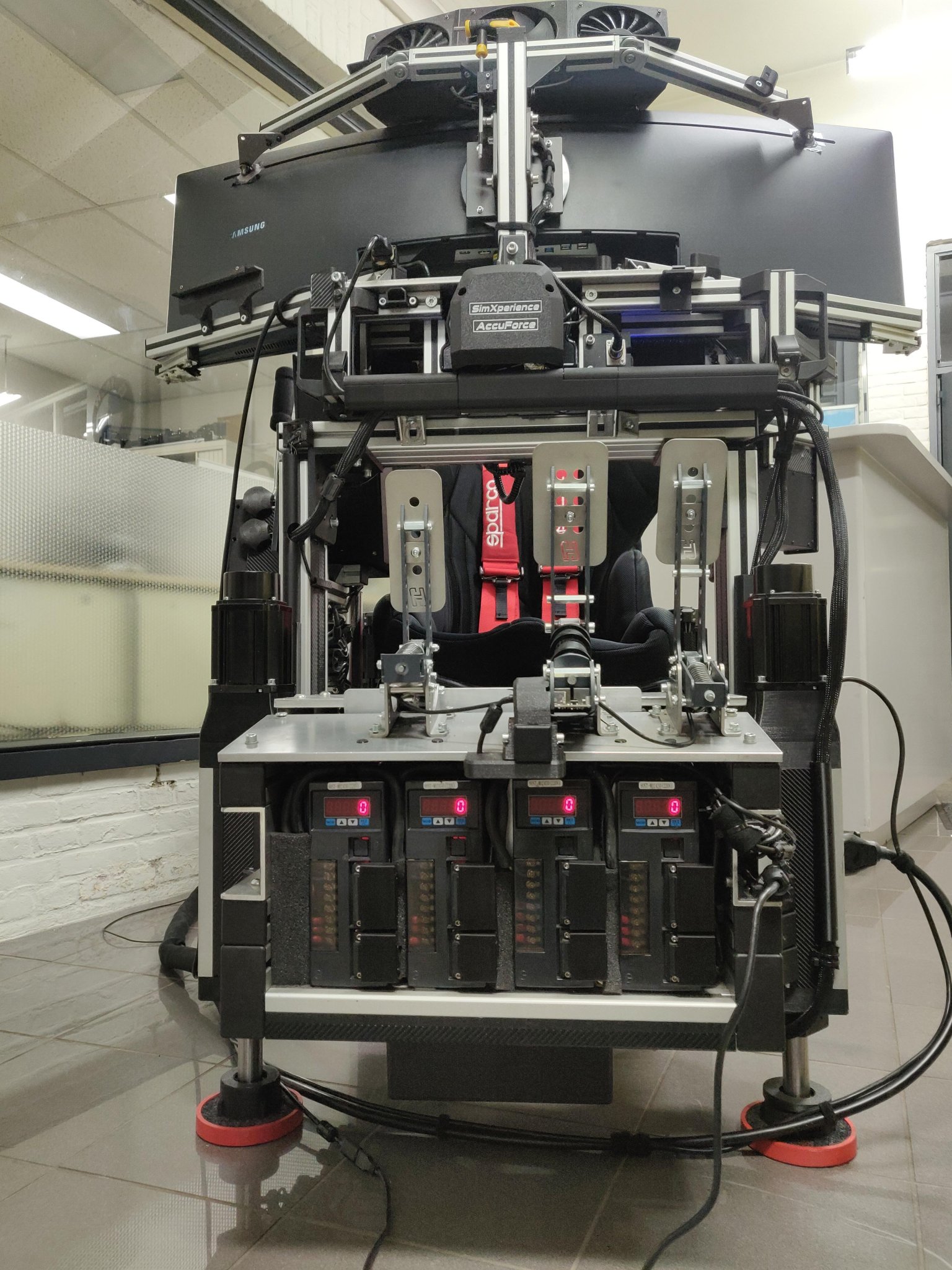

It has been a while since the latest update.

In that time a lot has changed on the rig. In fact there have been so many changes that we can call this a mega update.

My rig is still a mobile rig and a lot focus has been on perfecting every aspect possible to quickly move the rig from one room to the other, connect to the PC and start racing ( in 2-3 minutes )

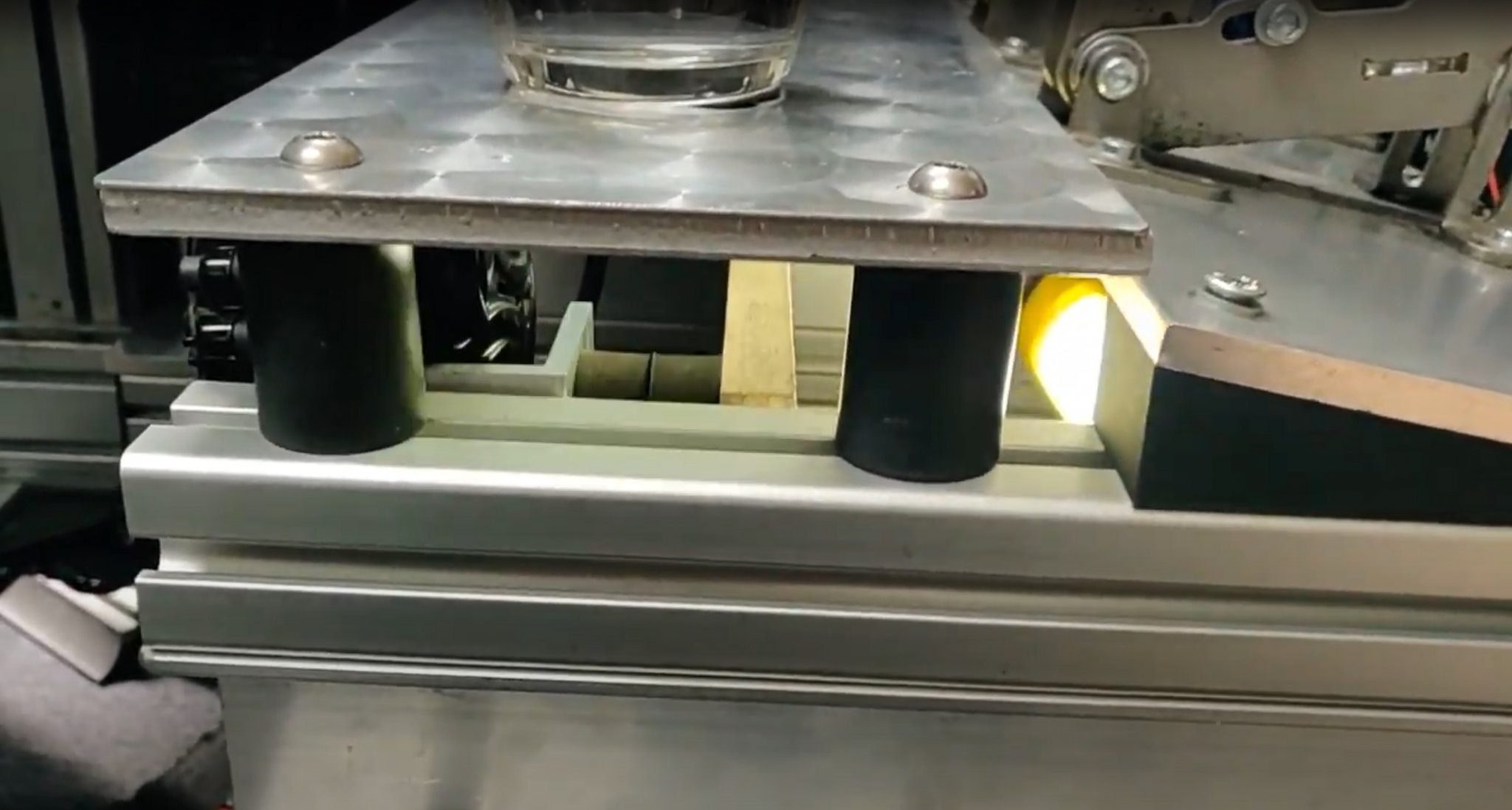

In Augustus 2020 i decided to mount all servo controllers on the rig under pedals. Now all electronics are integrated in the rig and this makes it much easier and faster to set up the rig and makes it even more portable.

For a clean and compact result i designed my own custom 90 degree angle connectors for the servos.

The servo controllers have a lot big parts in them which could be affected by the movements of the SFX, so i opened up all servo controllers and reinforced the all the electronics with hot glue.

The MDF plate on which the controllers are mounted is secured to rig with 4 rubber isolators.

This eliminates all vibrations from the Buttkickers which are less then 10cm from the servo controllers and also protects them from the vibrations of the SFX.

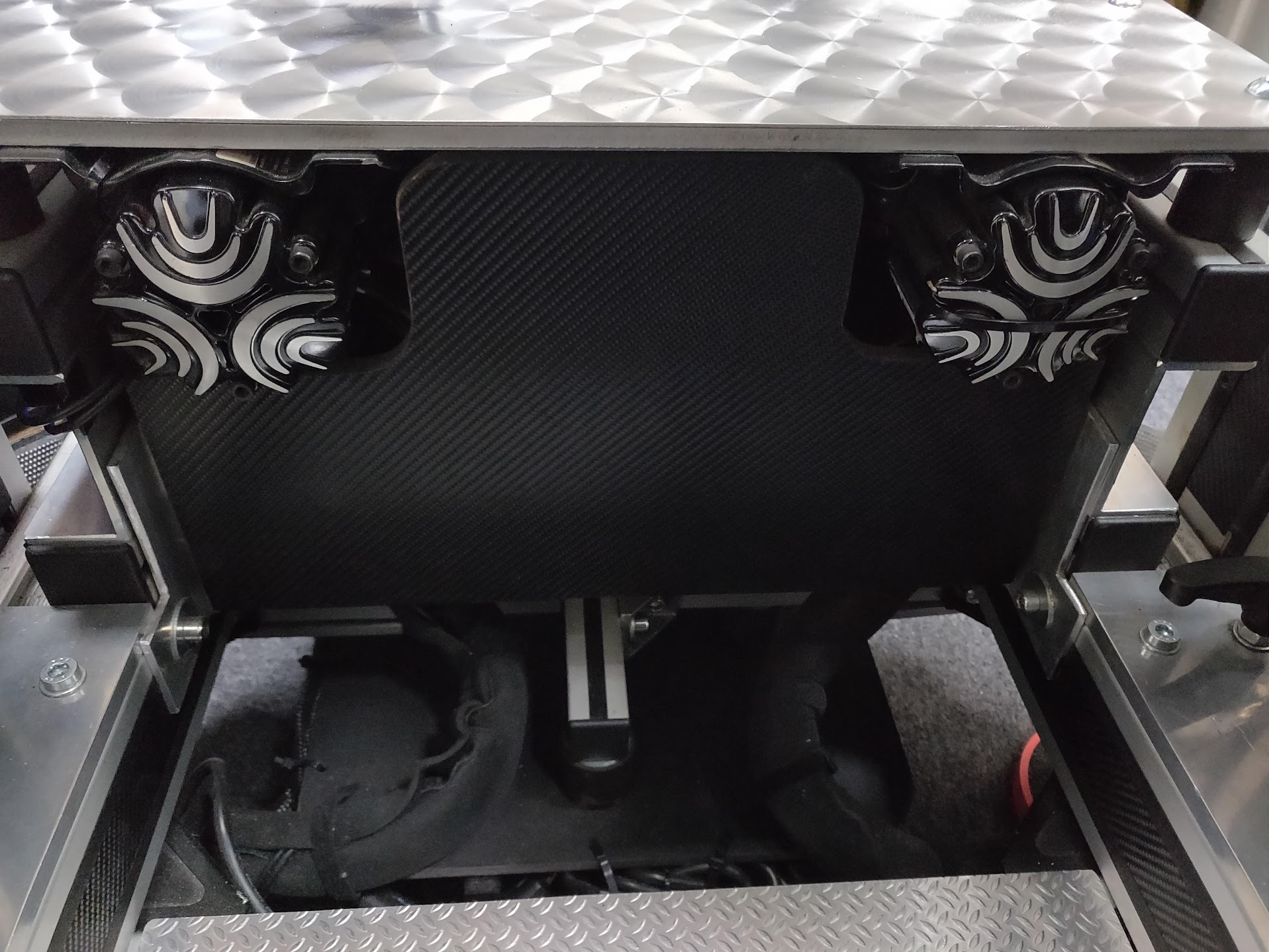

The pedal plate has 2 mini LFE's attached to it and is mounted on 4 isolators. The Buttkickers are mounted in a 90 degree angle to the rubbers of the isolators allowing small movements of the entire heel plate. At 40% volume they produce more power than i need at my feet.

It really unbelievable how powerful these 2 mini LFE's are when they only have to shake one small heel plate. Good isolation of tactile is extremely important.

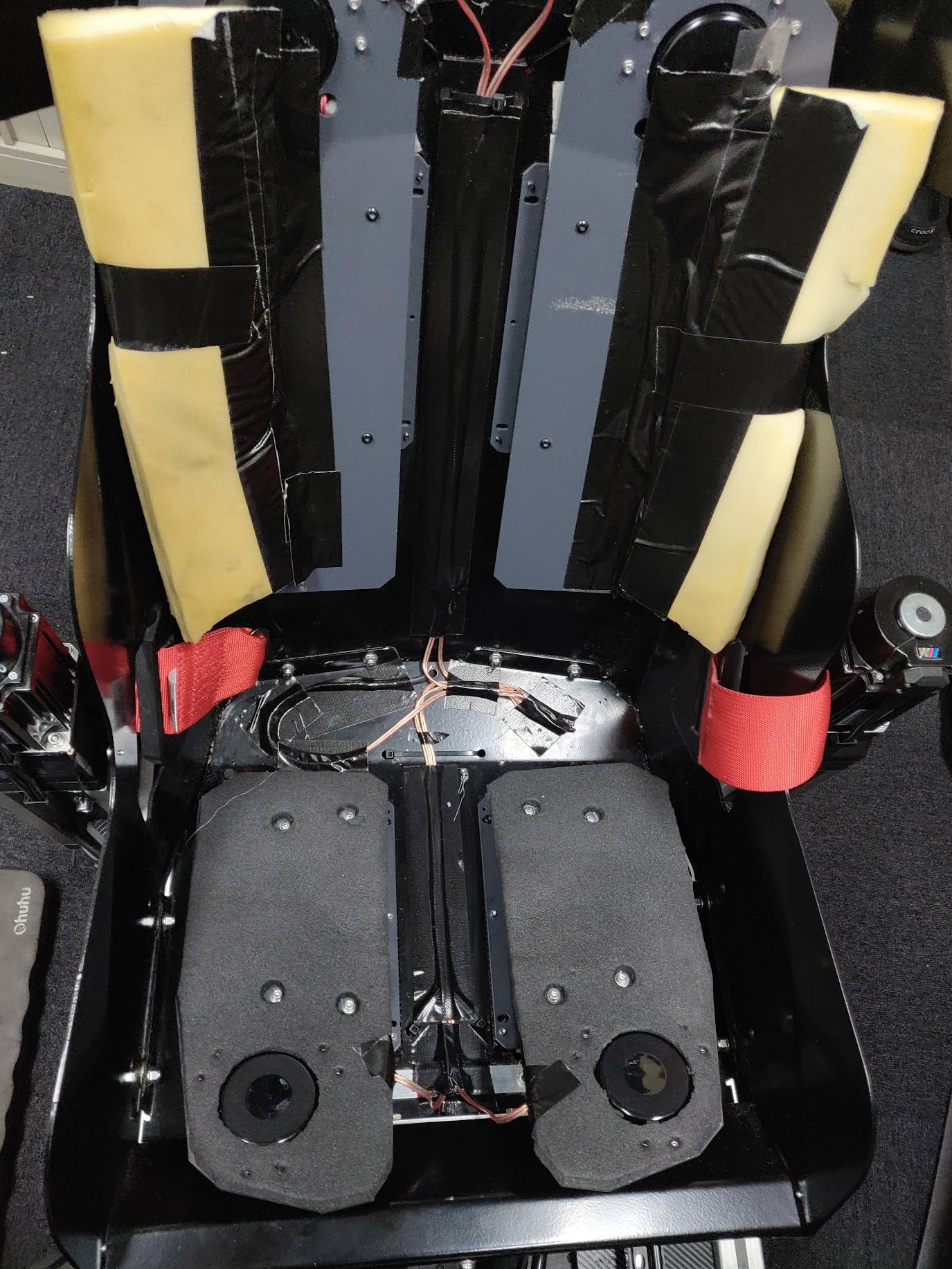

The four GS-5 panels now each have their own exciter mounted to them. These panels themselves are isolated from the seat since they are only attached with a couple of hinges. The performance of these Dayton Pucks is far beyond my expectation.

Because the max number of connections on the 13 pole connector was already reached, i had sacrifice the tactile feedback on the shifter. However the amount of feedback ( engine RPM ) i get from these 4 Dayton pucks is so good, it a sacrifice i'm gladly willing to make.

The GS-5 has gone through some modifications to. Better placement of the bottom panels, extended the hole of the shoulder belts and added extra foam ( almost every where ) giving me a tighter fit into the seat.

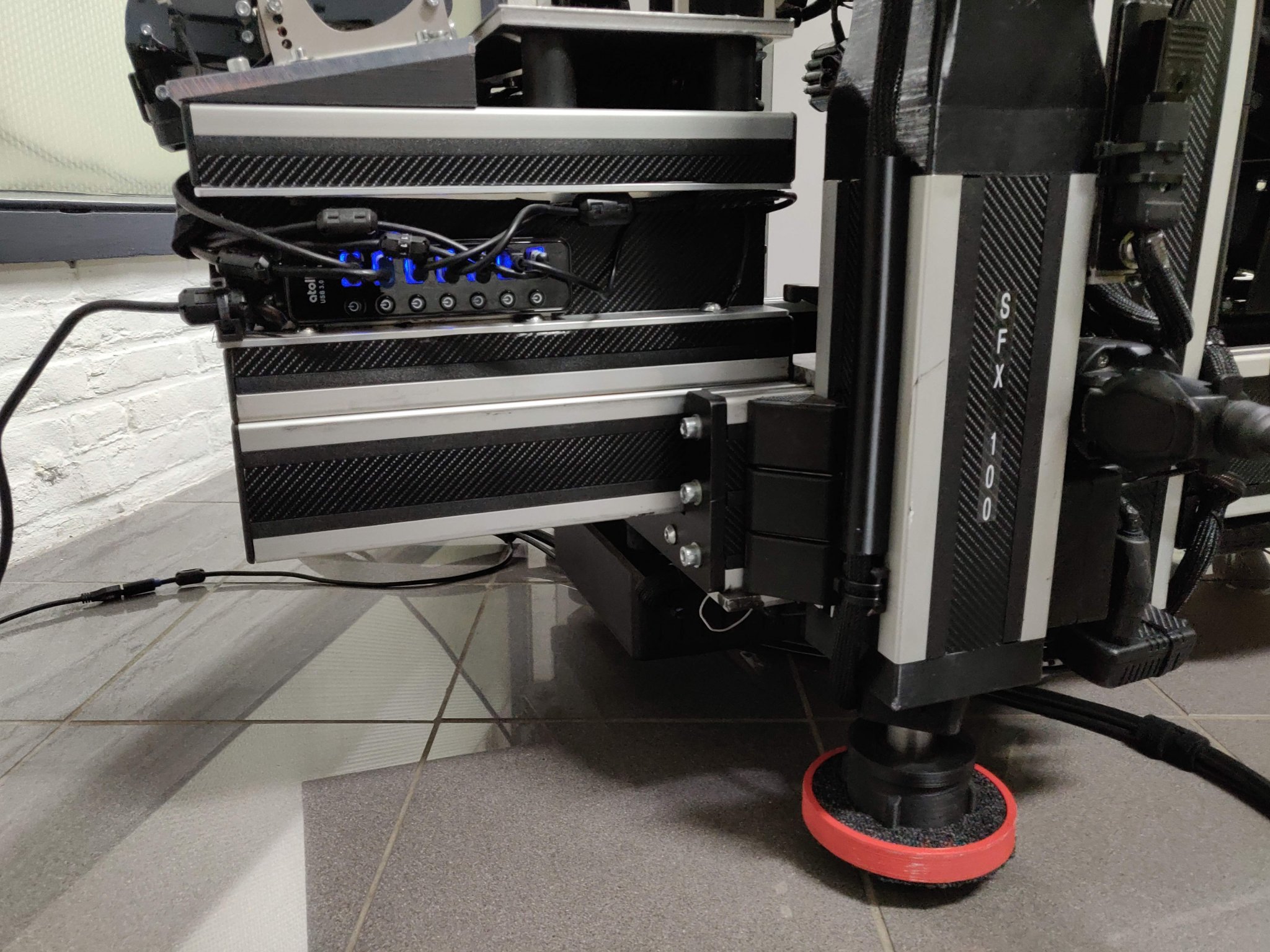

The 4 seat belt tensioner has been upgraded to the 3rd version, with better torque and serviceability.

I decided to group the buttons on the curved carbonfiber dashboard & center console by adding different colored edges around specific button groups.

This something i have been wanted to do for a very long while.

I made a second version the push-pull shifter. This second version has the real carbon fiber high gloss upgrade and a quick release system that allows me to mount it in less time it would take to exchange a wheel with the QR1.

In that time a lot has changed on the rig. In fact there have been so many changes that we can call this a mega update.

My rig is still a mobile rig and a lot focus has been on perfecting every aspect possible to quickly move the rig from one room to the other, connect to the PC and start racing ( in 2-3 minutes )

In Augustus 2020 i decided to mount all servo controllers on the rig under pedals. Now all electronics are integrated in the rig and this makes it much easier and faster to set up the rig and makes it even more portable.

For a clean and compact result i designed my own custom 90 degree angle connectors for the servos.

The servo controllers have a lot big parts in them which could be affected by the movements of the SFX, so i opened up all servo controllers and reinforced the all the electronics with hot glue.

The MDF plate on which the controllers are mounted is secured to rig with 4 rubber isolators.

This eliminates all vibrations from the Buttkickers which are less then 10cm from the servo controllers and also protects them from the vibrations of the SFX.

The pedal plate has 2 mini LFE's attached to it and is mounted on 4 isolators. The Buttkickers are mounted in a 90 degree angle to the rubbers of the isolators allowing small movements of the entire heel plate. At 40% volume they produce more power than i need at my feet.

It really unbelievable how powerful these 2 mini LFE's are when they only have to shake one small heel plate. Good isolation of tactile is extremely important.

The four GS-5 panels now each have their own exciter mounted to them. These panels themselves are isolated from the seat since they are only attached with a couple of hinges. The performance of these Dayton Pucks is far beyond my expectation.

Because the max number of connections on the 13 pole connector was already reached, i had sacrifice the tactile feedback on the shifter. However the amount of feedback ( engine RPM ) i get from these 4 Dayton pucks is so good, it a sacrifice i'm gladly willing to make.

The GS-5 has gone through some modifications to. Better placement of the bottom panels, extended the hole of the shoulder belts and added extra foam ( almost every where ) giving me a tighter fit into the seat.

The 4 seat belt tensioner has been upgraded to the 3rd version, with better torque and serviceability.

I decided to group the buttons on the curved carbonfiber dashboard & center console by adding different colored edges around specific button groups.

This something i have been wanted to do for a very long while.

I made a second version the push-pull shifter. This second version has the real carbon fiber high gloss upgrade and a quick release system that allows me to mount it in less time it would take to exchange a wheel with the QR1.

Last edited:

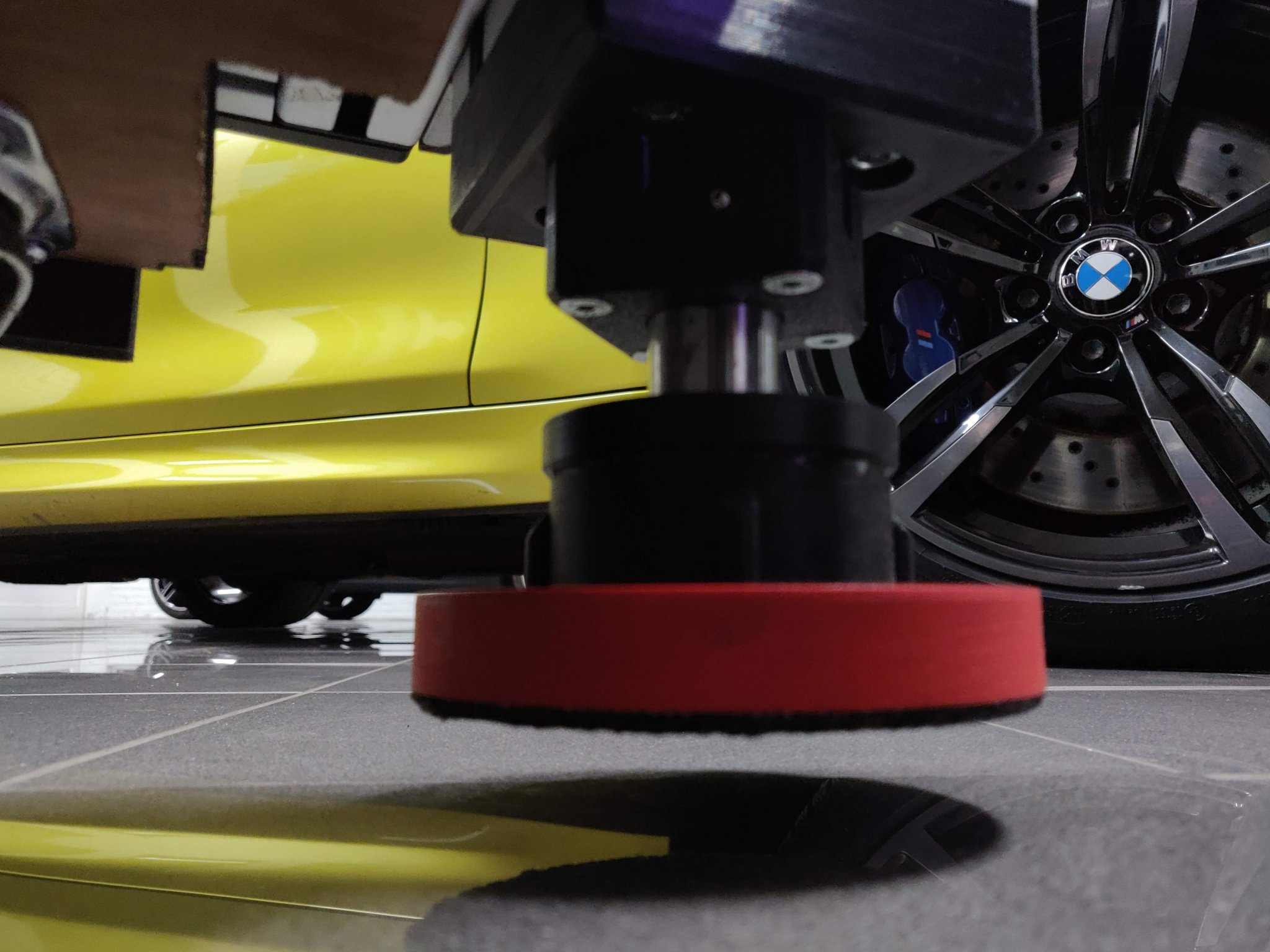

Normally i use the rig in my office, but during the covid period it was not possible to have friends and relations over in such a small space. So i made extensions cables so i can use the rig in the much larger showroom

In the background you can see my office and my “simracing closet”

Now, 1,5 years later, i'm still amazed that i can run my entrire simulator with 14 USB devices from one USB cable to the other room using a 3m extension cable ( problem free )

The entire rig has been modified to a carbon / black / grey theme about a year ago.

Last but not least there has been A LOT of cable management. I added cable guides on multiple places on the rig. On the back of the dashboard almost all cables are hidden into the 3d printed cable guide.

When all was finished, those big connectors of the servo kept on bothering me. A couple of months later i cut them of and soldered the wires together so i could hide the entire wire into the 80/20 profile

When i used to move the rig into my office, i had to put pads under the feet to protect the carpet every time. Now these pads are fixed to the rods of the SFX, so they stick when the rig is put on the cart.

The under side also has carpet. Carpet on carpet eliminates the "walking" of my SFX in the office.

I replaced the LMEK30UU with the more quiet IGUS bearings. This did not only reduce the noise of my SFX100, but also created more room inside the actuator.

I have changed the servo settings to take advantage of that extra room and have transformed my SFX100 into a SFX125.

New Seaflos because of the bearings was starting to make noise and these fans are right into my face, it's better to be safe then sorry.

The windsim mount has also received an upgrade and can quickly be mounted with only two bolts and more cleaner cable management.

Changing from VR rig ( with Seaflos ) to rig with 49" monitor takes less then a minute due to lot's of optimizations.

The PC that powers it all is currently a 12900K with 32GB ram and a RTX 3090. The PC is watercooled and on top there's 200mm fan blowing the hot air out from under the desk.

When the simrig is parked during the day, it's a compact package. The pedal tray is fully retracted and the dashboard is moved to left. In the storage position the rig takes less than 1 square meter footprint, but still houses 14 usb devices, 9 tactile transducers, 7 servo controllers.

A lot customers notice the rig and it’s always a good topic of conversation and admiration.

In the background you can see my office and my “simracing closet”

Now, 1,5 years later, i'm still amazed that i can run my entrire simulator with 14 USB devices from one USB cable to the other room using a 3m extension cable ( problem free )

The entire rig has been modified to a carbon / black / grey theme about a year ago.

Last but not least there has been A LOT of cable management. I added cable guides on multiple places on the rig. On the back of the dashboard almost all cables are hidden into the 3d printed cable guide.

When all was finished, those big connectors of the servo kept on bothering me. A couple of months later i cut them of and soldered the wires together so i could hide the entire wire into the 80/20 profile

When i used to move the rig into my office, i had to put pads under the feet to protect the carpet every time. Now these pads are fixed to the rods of the SFX, so they stick when the rig is put on the cart.

The under side also has carpet. Carpet on carpet eliminates the "walking" of my SFX in the office.

I replaced the LMEK30UU with the more quiet IGUS bearings. This did not only reduce the noise of my SFX100, but also created more room inside the actuator.

I have changed the servo settings to take advantage of that extra room and have transformed my SFX100 into a SFX125.

New Seaflos because of the bearings was starting to make noise and these fans are right into my face, it's better to be safe then sorry.

The windsim mount has also received an upgrade and can quickly be mounted with only two bolts and more cleaner cable management.

Changing from VR rig ( with Seaflos ) to rig with 49" monitor takes less then a minute due to lot's of optimizations.

The PC that powers it all is currently a 12900K with 32GB ram and a RTX 3090. The PC is watercooled and on top there's 200mm fan blowing the hot air out from under the desk.

When the simrig is parked during the day, it's a compact package. The pedal tray is fully retracted and the dashboard is moved to left. In the storage position the rig takes less than 1 square meter footprint, but still houses 14 usb devices, 9 tactile transducers, 7 servo controllers.

A lot customers notice the rig and it’s always a good topic of conversation and admiration.

Last edited:

such a great rig, rig report .....

since i am part of simracing i always saw some of your projects

so maybe you are one of those guys who inspired me to do all my crazy stuff

RESPECT - i love the M4 rig combo - i am still waiting to get my M8 GTE to make the same picture

i see 2 problems

- i will not get one

- if i get one, i cannot park him in my basement

Cheers

Peter

since i am part of simracing i always saw some of your projects

so maybe you are one of those guys who inspired me to do all my crazy stuff

RESPECT - i love the M4 rig combo - i am still waiting to get my M8 GTE to make the same picture

i see 2 problems

- i will not get one

- if i get one, i cannot park him in my basement

Cheers

Peter

Latest News

-

F1 24’s Updated Driver Career Mode DetailedThe new aim of F1 24's driver career is to increase your recognition levels, and ultimately...

- Thomas Harrison-Lord

- Updated:

- 3 min read

-

Assetto Corsa Competizione’s Nordschleife Hits Consoles 2nd MayThe Nürburgring 24hr Pack DLC for Assetto Corsa Competizione arrives this time next week for...

- Thomas Harrison-Lord

- Updated:

- 2 min read

-

BeamNG Hotfix Adds Vehicle Detail Viewer And A Slew Of FixesBeamNG.drive's 0.32 update has been a huge hit with fans, the obligatory patch to partner the...

- Connor Minniss

- Updated:

- 3 min read

-

Gran Turismo 7’s Update 1.46 Includes Škoda’s Vision GTAn electric concept marks Škoda’s debut within Gran Turismo, and it will be joined by Honda’s...

- Thomas Harrison-Lord

- Updated:

- 4 min read

-

F1 Manager 2024’s New Mentality System, Pitbox Order DetailedAlongside being able to create a custom team, drivers can now be poached, races can be simulated...

- Thomas Harrison-Lord

- Updated:

- 2 min read

-

How The BTCC and Motorsport Games ReunitedIn a surprise move last week, official BTCC content will once again be present within rFactor 2...

- Thomas Harrison-Lord

- Updated:

- 5 min read

-

Sponsored MOZA Racing & Lamborghini Redefine Racing Boundaries with The Real Race Super Trofeo 2024MOZA Racing proudly announces its collaboration with Lamborghini for the launch of The Real Race...

- OverTake.gg

- Updated:

- 6 min read