I'm thinking of upgrading to an actual sim rig and am trying to decide between building my own with 8020 or going with a pre built one, probably the gt1 evo.

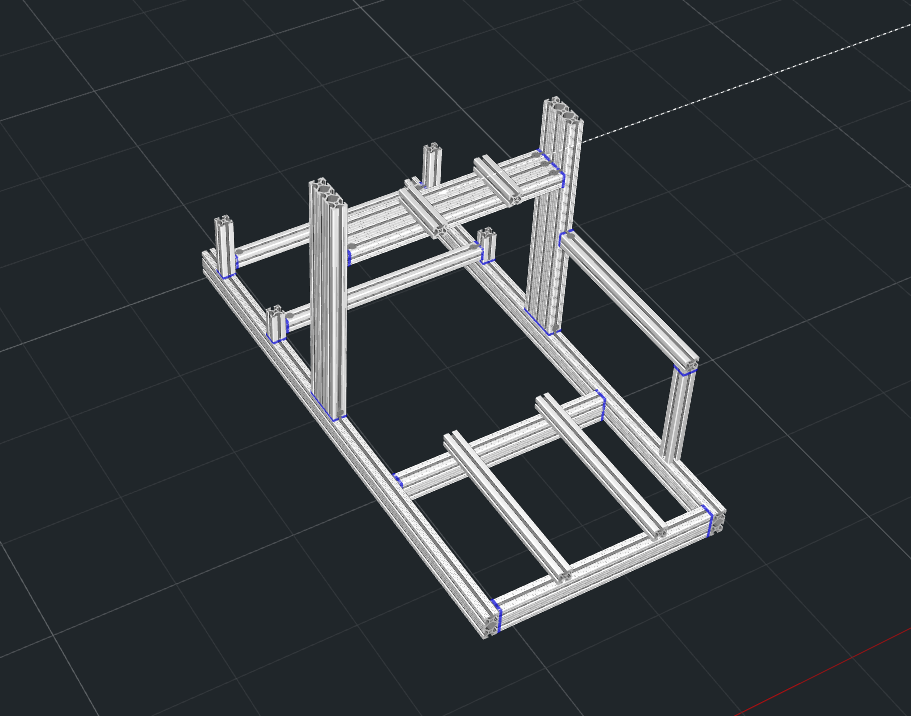

Here is an image of what I came up with in Frame Designer. It's 55"x23" and the vertical wheel posts are 26". This is using mostly 1.5"x3" from Tnutz. Except for the wheel posts and wheel deck, that's 1.5"x4.5". I threw together a similar one using 1.5"x4.5" for the base as well. I feel like that is probably overkill though.

I've never worked with 8020 before and this design is pretty similar to what other people have done. I'm just looking for some feedback from someone with more experience and if there are any major changes I should look into.

I don't know if the seat mounting or pedal area's would work. I'm looking to try and get the Proto Simtech PT2's when they are available and pull a seat out of an old car.

I'm planning on getting the simucube 2 pro so that's why I was thinking of going the diy 8020 route instead of the Gt1 evo from simlab.

Also has anyone built a rig out of wood. I was thinking using 2x4's as the frame would be a lot cheaper but I don't know how sturdy it would be.

Thanks for the help.

Here is an image of what I came up with in Frame Designer. It's 55"x23" and the vertical wheel posts are 26". This is using mostly 1.5"x3" from Tnutz. Except for the wheel posts and wheel deck, that's 1.5"x4.5". I threw together a similar one using 1.5"x4.5" for the base as well. I feel like that is probably overkill though.

I've never worked with 8020 before and this design is pretty similar to what other people have done. I'm just looking for some feedback from someone with more experience and if there are any major changes I should look into.

I don't know if the seat mounting or pedal area's would work. I'm looking to try and get the Proto Simtech PT2's when they are available and pull a seat out of an old car.

I'm planning on getting the simucube 2 pro so that's why I was thinking of going the diy 8020 route instead of the Gt1 evo from simlab.

Also has anyone built a rig out of wood. I was thinking using 2x4's as the frame would be a lot cheaper but I don't know how sturdy it would be.

Thanks for the help.