AS noted in several threads, I have a real racecar. Its a 1990 Miata converted into a Spec Miata (SM) and I race with the National Auto Sports Association (NASA), and the Sports Car Club of America (SCCA). For a couple different reasons, my race season in 2020 and probably 2021 has been/will be non-existent. So, I've turned to iRacing and the MX-5 Cup car (mostly) as continue training. To that end, I want my rig to reflect the ergonomics of my actual cockpit as much as practical.

The wheel (not pictured) is a Momo 78. The seat is a 16" Ultrashield VS Road Race Halo (20 deg layback). Note, the above pics were taken mid-rebuild after a rather serious wreck....hence the shattered windshield, and wires hanging loose.

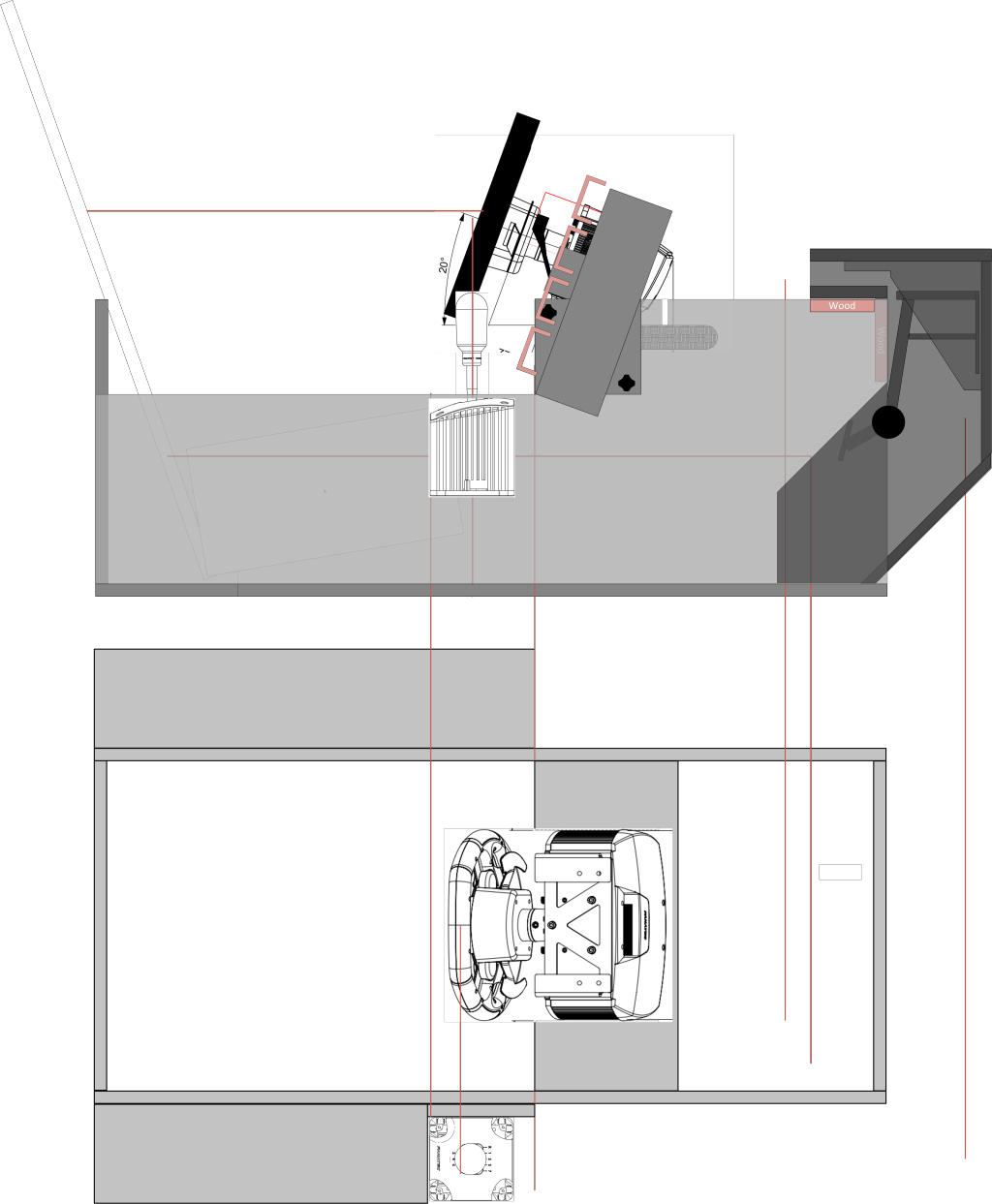

Besides wanting to replicate my SM controls, my other constraint is space. I don't have a place for a dedicated rig, and I use my computer for working from home these days. So, the rig needs to be portable, and compact...and reasonably cosmetically pleasing when not in use. To that end I opted for VR (Rift S) rather than a triple setup, and a coffin style overall design, DIY out of wood. The general idea is that it can be folded inside itself when not in use and become a "bench" or coffee table.

The idea is that all the parts that protrude beyond the boundaries of the "box" can be removed, and tucked inside or fold into it on hinges of some kind.

I've used scale drawings of Fanatec parts for proof of concepts, because a friend was going to sell me his CSW 2.5+V3 pedals+shifter setup when he upgraded to SC2/Quaife/Heusinkveld. Now that he's building a racecar, too...I'm guessing his money priorities have shifted. So, I'll probably replace with Accuforce V2, and a TBD H-pattern. I have an old Logitech Momo that I bought ages and ages ago.

For the pedals, I have a spare set of miata pedals: Clutch, Throttle, and brake. I'm mid build in converting those into a load-cell brake, and linear pot based clutch/throttle. The pedals will be mounted in a box which will hang off the end, and slide inside when not in use.

The seat I plan to use is an expired FIA Sparco Circuit Pro. Its not the same seat as the race car, but its also a halo seat, but I've found that the tactile Exciters work quite a bit better on the composite material than they did on the aluminum. I was going to use it in the car, but it won't fit in around the roll-cage. So, its been sitting on the shop collecting dust and spiders.

I started a separate thread on the Button Box, yesterday. That's here.

For tactile, I'm still very early stages in planning that. But, I currently have 4 DAEX32P-4, and have another 4 on order. I also scored a BK-LFE yesterday for less than half-price.

Anyway....that's a start at this build thread.

The wheel (not pictured) is a Momo 78. The seat is a 16" Ultrashield VS Road Race Halo (20 deg layback). Note, the above pics were taken mid-rebuild after a rather serious wreck....hence the shattered windshield, and wires hanging loose.

Besides wanting to replicate my SM controls, my other constraint is space. I don't have a place for a dedicated rig, and I use my computer for working from home these days. So, the rig needs to be portable, and compact...and reasonably cosmetically pleasing when not in use. To that end I opted for VR (Rift S) rather than a triple setup, and a coffin style overall design, DIY out of wood. The general idea is that it can be folded inside itself when not in use and become a "bench" or coffee table.

The idea is that all the parts that protrude beyond the boundaries of the "box" can be removed, and tucked inside or fold into it on hinges of some kind.

I've used scale drawings of Fanatec parts for proof of concepts, because a friend was going to sell me his CSW 2.5+V3 pedals+shifter setup when he upgraded to SC2/Quaife/Heusinkveld. Now that he's building a racecar, too...I'm guessing his money priorities have shifted. So, I'll probably replace with Accuforce V2, and a TBD H-pattern. I have an old Logitech Momo that I bought ages and ages ago.

For the pedals, I have a spare set of miata pedals: Clutch, Throttle, and brake. I'm mid build in converting those into a load-cell brake, and linear pot based clutch/throttle. The pedals will be mounted in a box which will hang off the end, and slide inside when not in use.

The seat I plan to use is an expired FIA Sparco Circuit Pro. Its not the same seat as the race car, but its also a halo seat, but I've found that the tactile Exciters work quite a bit better on the composite material than they did on the aluminum. I was going to use it in the car, but it won't fit in around the roll-cage. So, its been sitting on the shop collecting dust and spiders.

I started a separate thread on the Button Box, yesterday. That's here.

For tactile, I'm still very early stages in planning that. But, I currently have 4 DAEX32P-4, and have another 4 on order. I also scored a BK-LFE yesterday for less than half-price.

Anyway....that's a start at this build thread.