Hi!

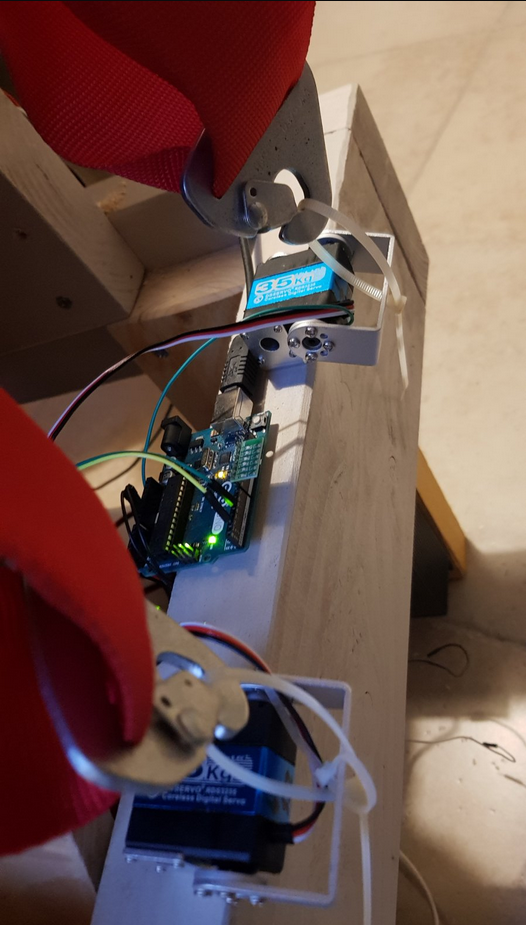

My cockpit is static, I've build a pressure gSeat with bladders and RC servo.

I wanted to increase immersion by a harness tensionner.

I'd already tested a static harness tensionner on a 2 DOF plateform, and the feeling was great.

As my rig is static, I'll have to actuate the harness but the advantage is that I can make a 2 DOF tensionner.

principle:

2 DOF harness -> the strength on the right shoulder and left shoulder will be different

both will react along Surge (longitudinal acceleration)

and Sway (lateral acceleration) will tight one shoulder or the other (depending on left turn or right turn)

(maybe later add some heave information?)

harness : 5 points

the 5th will prevent the harness to move up, this will give actual tension (vs movement)!

prefer larger harness 3" (vs only 2")

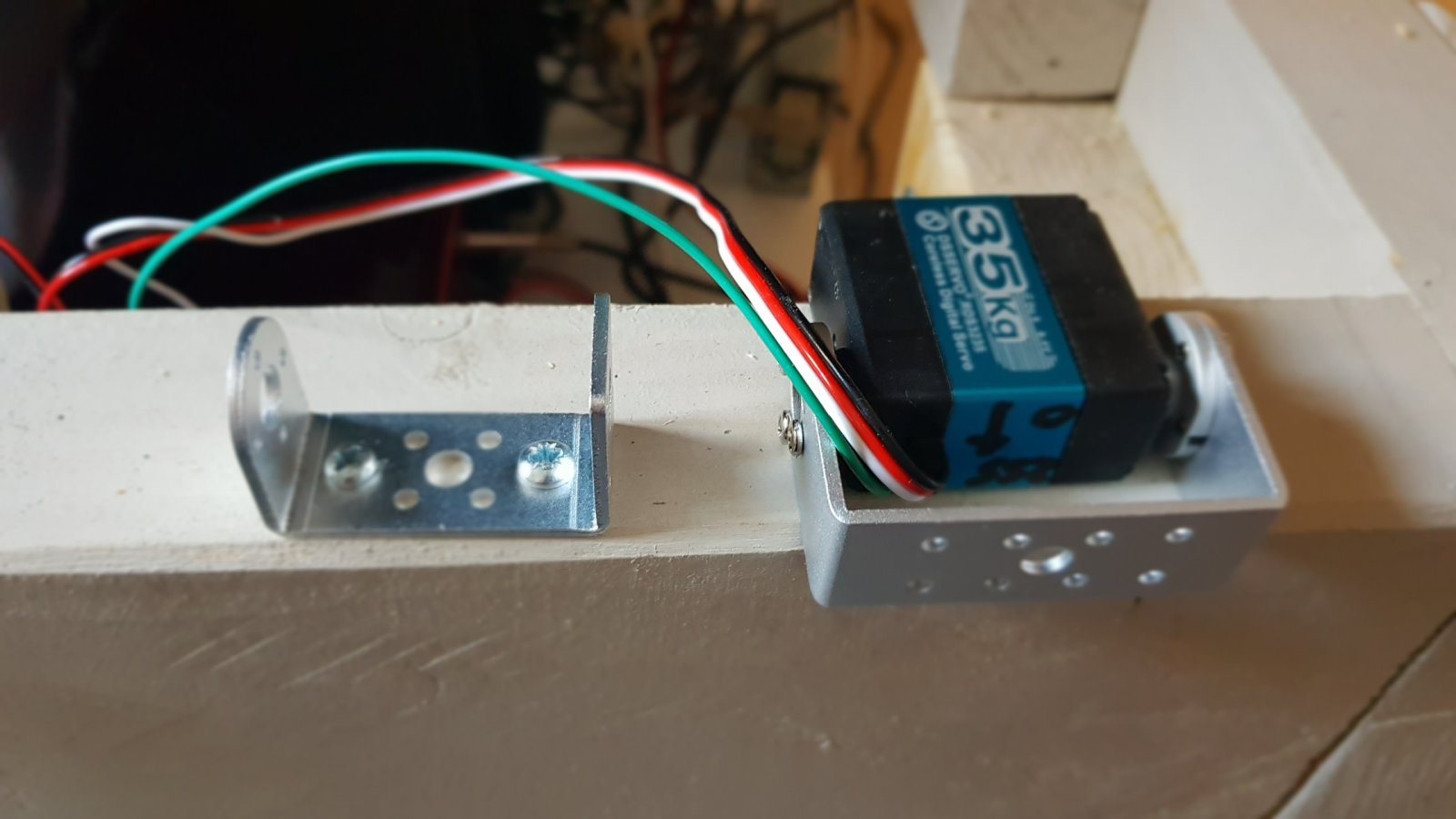

actuators:

RC servos 35kg.cm (5V to 8,3V)

PSU @7,3V

arduino:

code for 4 servos as I want to combine the harness and the gSeat pressure bladders also RC servo driven.

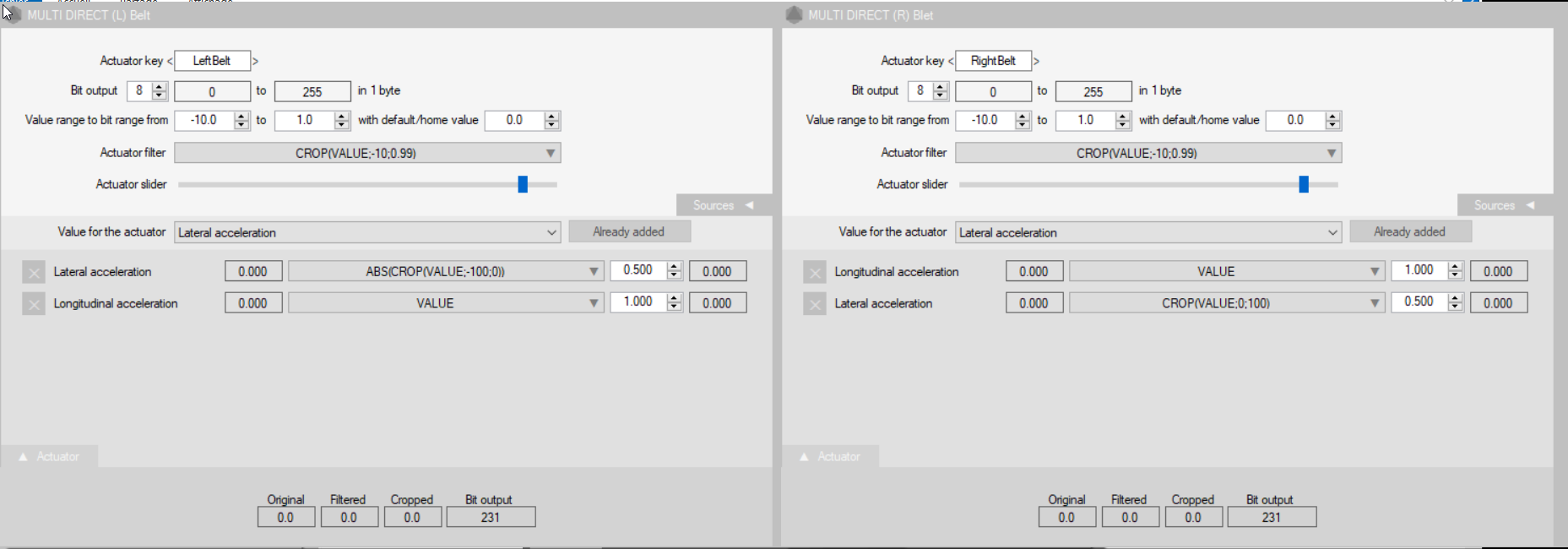

software:

FlyPT mover https://www.xsimulator.net/community/faq/flypt-mover.29/category

Here is a video showing step by step how I drive the 2 DOF belt with Fly PTmover:

The strength from 35kg.cm servo is enough.

Power up the servo, sit down, thight the belt as you wish, and start the sim. If you tight the belt before powering up the servos, they are loose and they could be pushed out of their range...

The only drawback, in my opinion is the noise of the servos: they are whinning...

here some infos gathered in this FAQ https://www.xsimulator.net/community/faq/harness-tensioner-simulation.361/

► shopping list

"HV high torque servo motor Robot servo 35kg RDS3235 Metal gear Coreless motor digital servo arduino servo for Robotic DIY"

www.aliexpress.com

17€

www.aliexpress.com

17€

I chose 270° range

You'll need a dedicated power supply (5V slower to 7,4V fastest)

Speed: 0.13sec/60 degree at(5v)

0.12sec/60 degree at(6v)

0.11sec/60 degree at(7.4v)

Torque: 29kg.cm.at(5v) -1.9A

32kg.cm.at(6v) -2.1A

35kg.cm.at(7.4v) -2.3A

or stronger but unecessary in my opinion

60kgcm 24€

https://www.aliexpress.com/item/4000055027119.html

speed is voltage related

torque is current related!

1/ choose speed AKA voltage

2/ check the spec which gives you the current at chosen voltage

3/ buy your PSU ;-)

if you choose 7,4V PSU, verify it'll be able to deliver up to 2.3A in order to give full torque (add a BIG margin ;-) )

https://fr.aliexpress.com/item/32823922664.html

11€ 7V 10A

here is my ball bearing support (12€ for 2 supports)

they are made of:

P000 https://www.aliexpress.com/item/32833812473.html

Zinc Alloy Diameter Bore Ball Bearing Pillow Block Mounted Support

they allow a big static disalignment as the bearing is mounted like a joint articulation

and 200mm Ø10 linear shaft Cylinder Chrome Plated Liner Rods

https://www.aliexpress.com/item/4001294745058.html

► budget:

2x 17€ for 35 kg.cm servo

11€ for 7V 10A PSU

(maybe consider a 12V 10A PSU + an Adjustable Power Module Constant Current 5A)

12€ for bearing rollers

15€ any arduino with a USB port (an original to support the community or a clone)

50€ for a used 3" width 5 points harness

total = 120€ all included

arduino code (for up to 4 servos)

here is the setup:

and the file itself: replace .txt extension by .Mover extension

My cockpit is static, I've build a pressure gSeat with bladders and RC servo.

I wanted to increase immersion by a harness tensionner.

I'd already tested a static harness tensionner on a 2 DOF plateform, and the feeling was great.

As my rig is static, I'll have to actuate the harness but the advantage is that I can make a 2 DOF tensionner.

principle:

2 DOF harness -> the strength on the right shoulder and left shoulder will be different

both will react along Surge (longitudinal acceleration)

and Sway (lateral acceleration) will tight one shoulder or the other (depending on left turn or right turn)

(maybe later add some heave information?)

harness : 5 points

the 5th will prevent the harness to move up, this will give actual tension (vs movement)!

prefer larger harness 3" (vs only 2")

actuators:

RC servos 35kg.cm (5V to 8,3V)

PSU @7,3V

arduino:

code for 4 servos as I want to combine the harness and the gSeat pressure bladders also RC servo driven.

software:

FlyPT mover https://www.xsimulator.net/community/faq/flypt-mover.29/category

Here is a video showing step by step how I drive the 2 DOF belt with Fly PTmover:

The strength from 35kg.cm servo is enough.

Power up the servo, sit down, thight the belt as you wish, and start the sim. If you tight the belt before powering up the servos, they are loose and they could be pushed out of their range...

The only drawback, in my opinion is the noise of the servos: they are whinning...

here some infos gathered in this FAQ https://www.xsimulator.net/community/faq/harness-tensioner-simulation.361/

► shopping list

"HV high torque servo motor Robot servo 35kg RDS3235 Metal gear Coreless motor digital servo arduino servo for Robotic DIY"

18.44€ 26% OFF|1X Hv High Torque Servo Motor Robot Servo 35Kg RDS3235 Metal Gear Coreless Motor Digital Servo Arduino Servo Voor robotic Diy|high torque servo|digital servorobot servo - AliExpress

Smarter Shopping, Better Living! Aliexpress.com

I chose 270° range

You'll need a dedicated power supply (5V slower to 7,4V fastest)

Speed: 0.13sec/60 degree at(5v)

0.12sec/60 degree at(6v)

0.11sec/60 degree at(7.4v)

Torque: 29kg.cm.at(5v) -1.9A

32kg.cm.at(6v) -2.1A

35kg.cm.at(7.4v) -2.3A

or stronger but unecessary in my opinion

60kgcm 24€

https://www.aliexpress.com/item/4000055027119.html

speed is voltage related

torque is current related!

1/ choose speed AKA voltage

2/ check the spec which gives you the current at chosen voltage

3/ buy your PSU ;-)

if you choose 7,4V PSU, verify it'll be able to deliver up to 2.3A in order to give full torque (add a BIG margin ;-) )

https://fr.aliexpress.com/item/32823922664.html

11€ 7V 10A

here is my ball bearing support (12€ for 2 supports)

they are made of:

P000 https://www.aliexpress.com/item/32833812473.html

Zinc Alloy Diameter Bore Ball Bearing Pillow Block Mounted Support

they allow a big static disalignment as the bearing is mounted like a joint articulation

and 200mm Ø10 linear shaft Cylinder Chrome Plated Liner Rods

https://www.aliexpress.com/item/4001294745058.html

► budget:

2x 17€ for 35 kg.cm servo

11€ for 7V 10A PSU

(maybe consider a 12V 10A PSU + an Adjustable Power Module Constant Current 5A)

12€ for bearing rollers

15€ any arduino with a USB port (an original to support the community or a clone)

50€ for a used 3" width 5 points harness

total = 120€ all included

arduino code (for up to 4 servos)

C++:

// Multi Direct

// -> 4 servos

// <255><LeftBelt><127><127><RightBelt>

// Rig : Bit output -> 8 bits

// avec inversion

// PT Mover envoie de 0 à 255 par axe

/*Mover = output "Binary" et "10bits"

Arduino = Byte Data[2]

Data[0] = Serial.read();

Data[1] = Serial.read();

result = (Data[0] * 256 + Data[1]);

OU

Mover = output "Binary" et "8bits"

Arduino = Byte Data

Data = Serial.read(); on obtient directement le résultat*/

#include <Servo.h> // local library "Servo.h" vs library partagée <Servo.h>

const byte nbServos = 4;

// create servo objects to control any servo

Servo myServo[nbServos];

const byte servoPin[nbServos] = {2, 3, 4, 5}; // pins digitales (pas forcément ~pwm)

const byte inversion[nbServos] = {1, 1, 0, 0 }; // paramètre à changer si un servo part le mauvais sens

int OldSerialValue[nbServos] = {0, 0, 0, 0};

int NewSerialValue[nbServos] = {0, 0, 0, 0};

// servo span:

int servoHomeDegres[nbServos] = { 0, 0, 0, 0}; //sera mis à jour avec la mesure de pression initiale

int servoMaxDegres[nbServos] = { 90, 90, 90, 90}; // cuisseG, cuisseD, côtéG, côtéD

int servoPositionTarget[nbServos] = {0, 0, 0, 0};

const byte deadZone = 0;

// =======================================

// Variables for info received from serial

// =======================================

int bufferPrevious = 0; // To hold previous read fom serial command

int bufferCurrent = 0; // To hold current read fom serial command

int bufferCount = 0; // To hold current position in bufferCommand array

// byte bufferCommand[2*nbServos] = {0}; // (*2 if 10 bits) To hold received info from serial

int bufferCommand[4] = {0}; // To hold received info from serial

void setup()

{

Serial.begin(115200); // opens serial port at specified baud rate

// attach the Servos to the pins

for (byte i = 0; i < nbServos; i++) {

// pinMode(servoPin[i], OUTPUT); // done within the library

myServo[i].attach(servoPin[i]); // attaches the servo on servoPin pin

}

// move the servos to signal startup

MoveAllServos255toDegres(125); // mi-course

delay(1000);

// send all servos to home

MoveAllServos255toDegres(0);

}

void loop()

{

// SerialValues contain the last order received (if there is no newer received, the last is kept)

if (Serial.available())

{

bufferPrevious = bufferCurrent; // Store previous byte

bufferCurrent = Serial.read(); // Get the new byte

bufferCommand[bufferCount] = bufferCurrent; // Put the new byte in the array

bufferCount++; // Change to next position in the array

if (bufferCurrent == 255) bufferCount = 0; // one 255 is the start of the position info

if (bufferCount == nbServos) //si 8 bits, nbServos // si 10 bits nbServos*2

//Having reach buffer count, means we have the new positions and that we can update the aimed position

{

for (byte i = 0; i < nbServos; i++) {

NewSerialValue[i] = bufferCommand[i];

//NewSerialValue[i]= (bufferCommand[i*2] * 256) + bufferCommand[i*2+1]; // si 10 bits

}

bufferCount = 0;

}

}

// Update orders sent to motor driver

for (byte i = 0; i < nbServos; i++) {

if (abs(OldSerialValue[i] - NewSerialValue[i]) > deadZone) {

if (inversion[i] == 1)

{

envoiServoConsigne255toDegres(i, (255 - NewSerialValue[i]));

}

else

{

envoiServoConsigne255toDegres(i, NewSerialValue[i]);

}

OldSerialValue[i] = NewSerialValue[i];

}

}

}

void envoiServoConsigne255toDegres(byte servoID, int val )

{

byte targetDegres;

val = constrain(val, 0, 255); // constrain coupe au dessus et en dessous : écrêtage et pas mise à l'échelle (comme map)

// sécurité pour éviter les cas où Simtools enverrait du négatif ou au-delà de 255

targetDegres = map(val, 0, 255, servoHomeDegres[servoID], servoMaxDegres[servoID]);

// map(value, fromLow, fromHigh, toLow, toHigh)

myServo[servoID].write(targetDegres); // tell servo to go to position in variable : in steps of 1 degree

// servo.write(angle) -> angle: the value to write to the servo, from 0 to 180

}

void MoveAllServos255toDegres( int target)

{

// send all servos to home

for (byte i = 0; i < nbServos; i++) {

envoiServoConsigne255toDegres(i, target);

}

}here is the setup:

and the file itself: replace .txt extension by .Mover extension

Attachments

Last edited: